Silicon-containing negative electrode material for lithium ion battery and preparation method of silicon-containing negative electrode material

A technology of lithium-ion batteries and negative electrode materials, applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc., can solve problems such as cycle performance deterioration, active material loss, material structure collapse, etc., to achieve optimization Rate performance, improved electrical conductivity, and improved volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

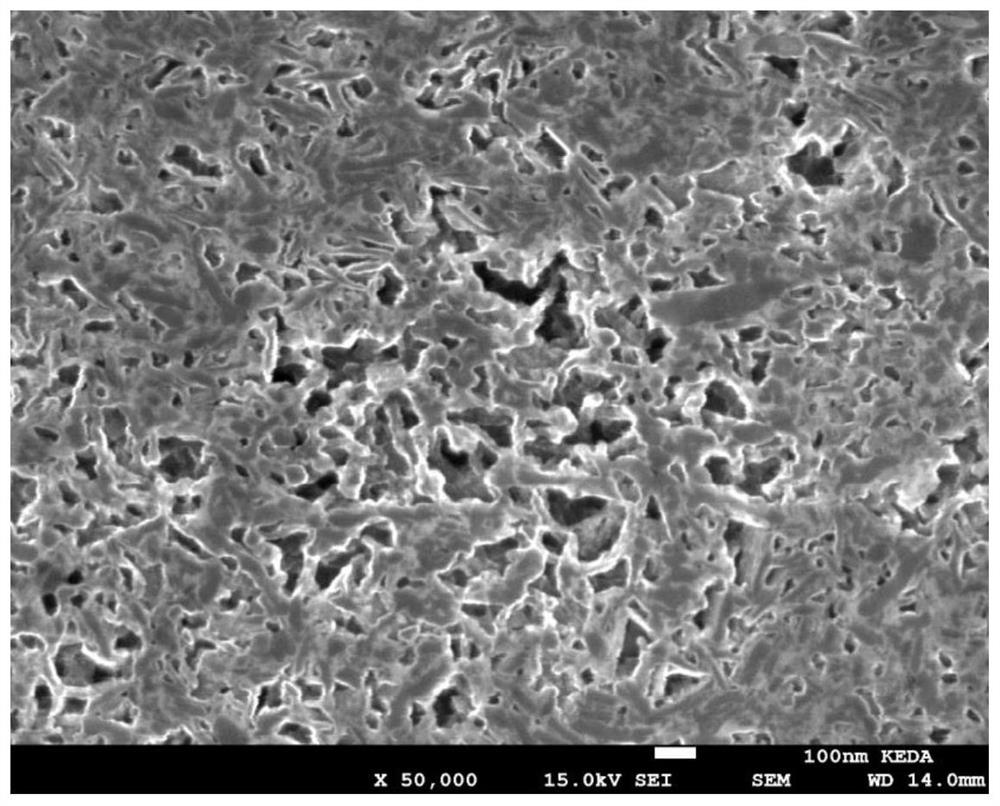

Image

Examples

Embodiment 1

[0033] A method for preparing a silicon-containing negative electrode material for a lithium ion battery, comprising the steps of:

[0034] (1) Preparation of porous carbon: Put glucose in a box furnace, pass in argon gas for gas protection, raise the temperature to 500°C at a heating rate of 3°C / min, keep it for 2h, and obtain a block formed by glucose decomposition after cooling Porous carbon: Grind the massive porous carbon to a fine powder, and sieve through a 325-mesh sieve to obtain the desired porous carbon;

[0035] (2) Preparation of nano-silicon: Add 1000 g of silicon powder with a median particle size of 1 μm and a purity of 99.99% and propanol into the dispersion tank of the sand mill, control the solid content of the mixed solution to be 10%, and then add grinding aid 3 Ethanolamine, the mass ratio of triethanolamine and silicon powder is 1:100, start stirring for 30 minutes; the material of the grinding beads is hard alloy, and the mass ratio of grinding beads an...

Embodiment 2

[0039](1) Preparation of porous carbon: put coal tar pitch with a median particle size of 10 μm in a box-type furnace, pass in nitrogen gas for gas protection, raise the temperature to 700 °C at a heating rate of 3 °C / min, stop nitrogen input, pass Into CO 2 After reacting for 3 hours, stop heating, cool to room temperature, and obtain a black powder; add the obtained black powder to excess concentrated hydrochloric acid, stir slowly, react for 20 hours, then fully wash with deionized water until neutral, and dry to obtain the obtained Need porous carbon;

[0040] (2) Preparation of nano-silicon: adding 1000 g of silicon powder with a median particle size of 5 μm and a purity of 99.97% and ethanol in the dispersion tank of the sand mill, controlling the solid content of the mixed solution to be 20%, and then adding grinding aid pyrophosphoric acid Sodium, the mass ratio of sodium pyrophosphate and silicon powder is 3:100, start stirring for 30 minutes; the material of the gri...

Embodiment 3

[0044] (1) Preparation of porous carbon: put the rice husk in a box-type furnace, pass helium gas into the gas protection, heat up to 850°C at a heating rate of 3°C / min, keep it warm for 2h, and obtain a carbonized product after cooling; combine the carbonized product with KOH is mixed in a mass ratio of 1:4, then added to pure water, stirred evenly, placed in an oven, and the temperature of the oven is controlled at 100°C until the mixture is dried; the dried powder is placed in a box furnace In the process, nitrogen was introduced for protection, and the temperature was raised to 650°C at a heating rate of 3°C / min, kept for 2 hours, cooled to room temperature, washed, dried, ground, and sieved through a 325-mesh sieve to obtain the desired porous carbon;

[0045] (2) Preparation of nano-silicon: Add 1000 g of silicon powder with a median particle size of 12 μm and a purity of 99.9% and isopropyl alcohol into the dispersion tank of the sand mill, control the solid content of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com