Silicon-containing powder for lithium ion battery negative electrode material and preparation method of silicon-containing powder

A technology for lithium-ion batteries and negative electrode materials, which is applied in the field of silicon-containing powders for lithium-ion battery negative electrode materials and its preparation, can solve problems affecting the first-time efficiency and cycle performance of batteries, and reduce the risk of spontaneous combustion, stabilize the powder structure, Reduces the effect of absolute volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of a lithium-ion battery negative electrode material containing silicon powder, comprising the steps of:

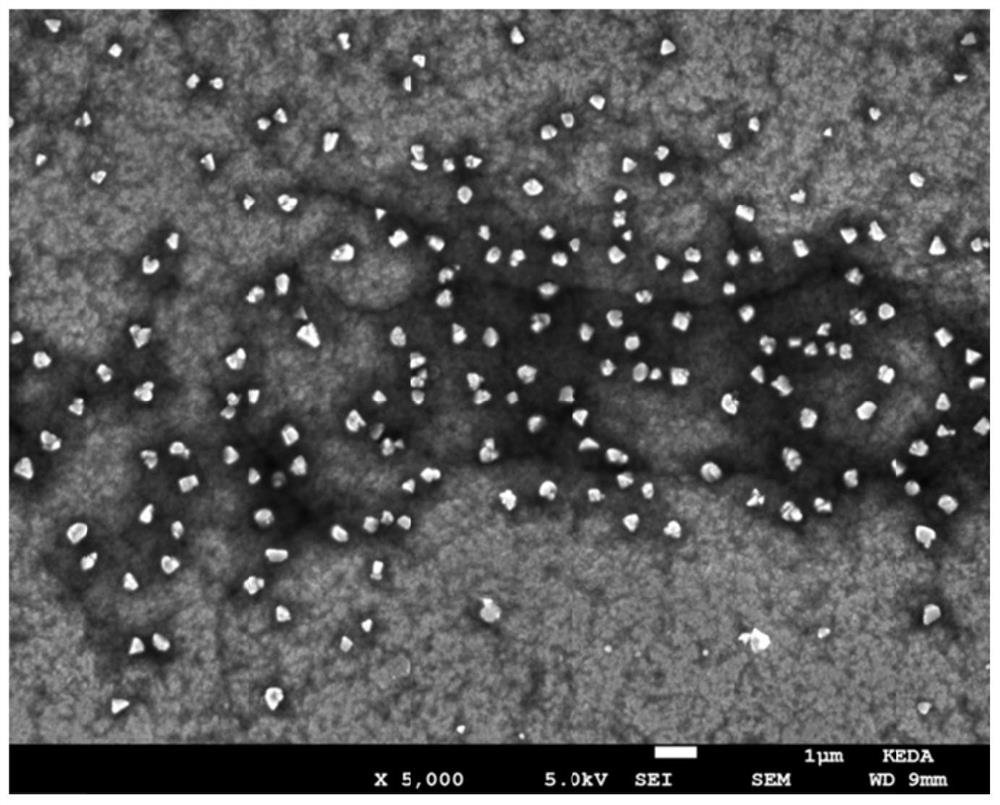

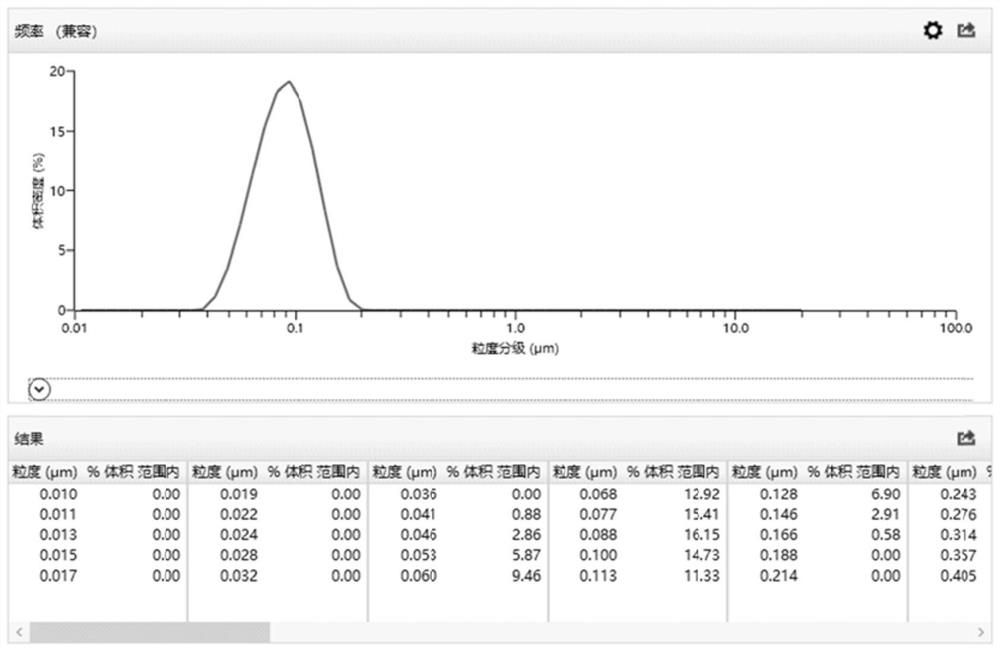

[0032] (1) Preparation of silicon-containing powder: Add 1000 g of silicon powder with a median particle size of 1 μm in the mixing tank supporting the sand mill, and the purity of the silicon powder is 99.92%, then add methanol in the mixing tank, and control the mixing tank. The solid content of the mixed solution is 10%, and the slow stirring is turned on, and 0.3mm zirconia beads are filled in the sand mill, and the mass ratio of zirconia beads to silicon powder is controlled to be 15:1, and the host speed of the sand mill is 1000rpm, grinding for 60h, the obtained silicon slurry was heated and dried to obtain a silicon-containing powder. Through detection, the median particle size D50 of the silicon-containing powder was 56nm, and the grain size of silicon was 7.9nm. The silicon powder contains 65.6 wt.% silicon, 26.3 wt.% oxygen and 8.1 w...

Embodiment 2

[0035] A preparation method of a lithium-ion battery negative electrode material containing silicon powder, comprising the steps of:

[0036] (1) Preparation of silicon-containing powder: Add 1000 g of silicon powder with a median particle size of 50 μm in the mixing tank supporting the sand mill, and the purity of the silicon powder is 99.53%, then add propanol in the mixing tank, and control the mixing tank The solid content of the mixed solution in the mixture is 15%, and the slow stirring is started, and 0.05mm zirconia beads are filled in the sand mill, and the mass ratio of the zirconia beads to the silicon powder is controlled to be 18:1, and the main machine speed of the sand mill is 18:1. Grind at 950rpm for 35h to obtain silicon slurry, and then heat and dry the silicon slurry to obtain a silicon-containing powder. The median particle size D50 of the silicon-containing powder is 71nm, and the grain size of silicon is 8.5nm. The silicon-containing powder Contains 74.4...

Embodiment 3

[0039] A preparation method of a lithium-ion battery negative electrode material containing silicon powder, comprising the steps of:

[0040] (1) Preparation of silicon-containing powder: Add 1000 g of silicon powder with a median particle size of 500 μm in the mixing tank supporting the sand mill, and the purity of the silicon powder is 99.67%, then add butanol in the mixing tank, and control the mixing tank The solid content of the mixed solution in the mixture is 10%, start slow stirring, fill the sand mill with 0.2mm zirconia beads, control the mass ratio of zirconia beads to silicon powder to 20:1, and the host speed of the sand mill Grinding at 900rpm for 50h, the obtained silicon slurry was heated and dried to obtain a silicon-containing powder. The median particle size D50 of the silicon-containing powder was 86nm, and the grain size of silicon was 10.3nm. The silicon-containing powder Contains 57.6wt.% of silicon, 24.1wt.% of oxygen and 18.3wt.% of zirconium;

[0041...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com