Titanium-aluminum-based high temperature alloy block preparing method based on thermal explosion reaction

A technology of superalloy and thermal explosion reaction, which is applied in the field of hot processing to achieve the effect of reducing room temperature brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solution of the present invention will be further described in detail below with reference to the embodiments:

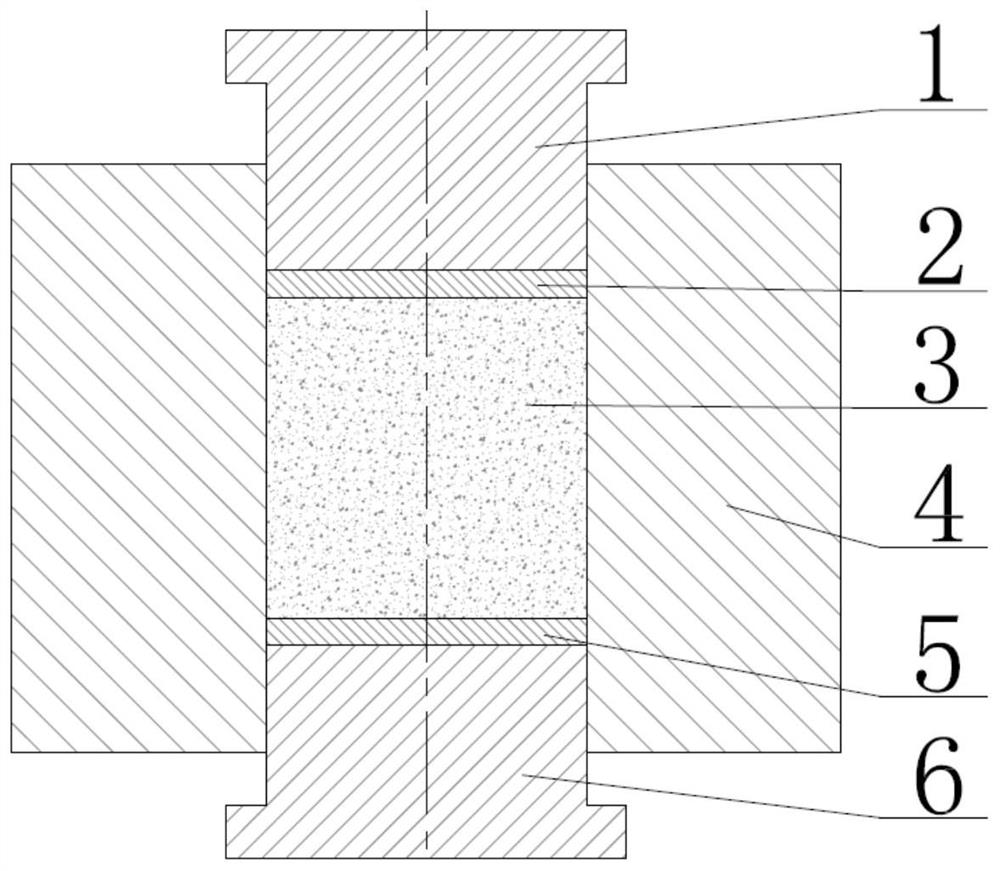

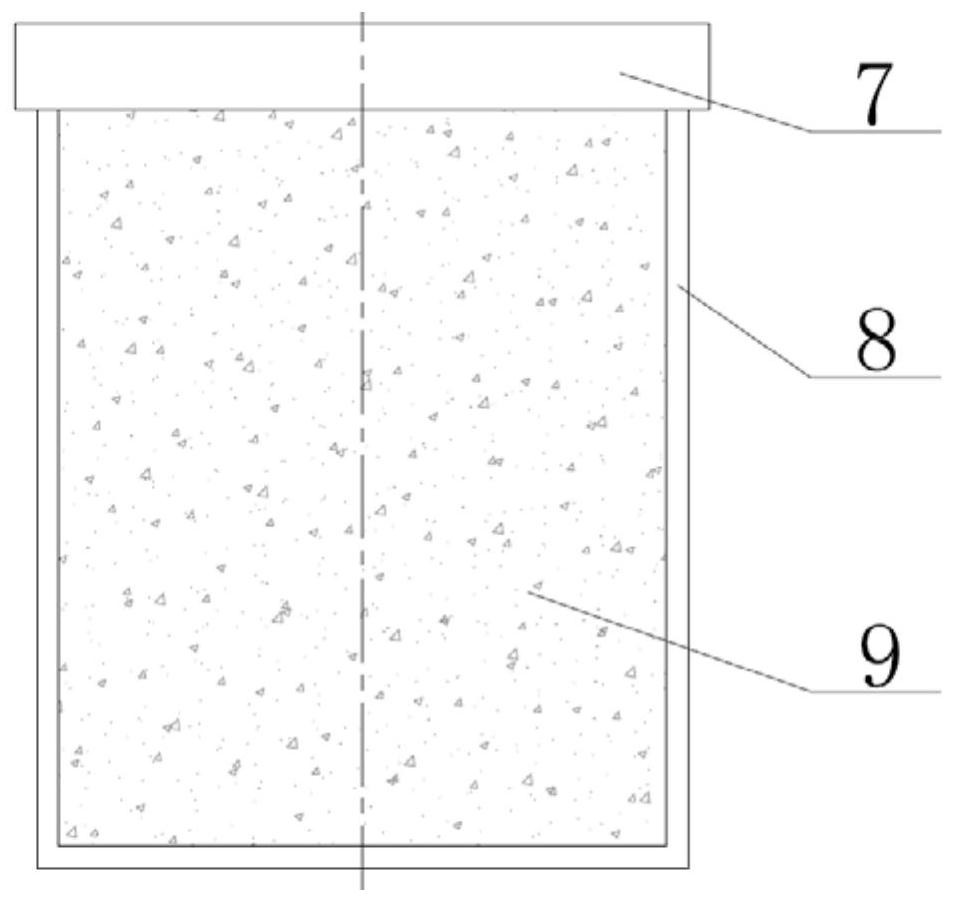

[0035] See attached Figure 1~3 As shown, the steps of the method for preparing the titanium-aluminum-based superalloy block based on the thermal explosion reaction described in this embodiment are as follows:

[0036] Step one, powder preparation

[0037] According to the weight of the titanium-aluminum-based superalloy block, weigh pure Ti powder, pure Al powder and titanium alloy powder with the same powder particle size. The mass ratio of the Ti powder and Al powder is consistent with the atomic ratio of the two, and the titanium alloy powder accounts for 5%-30% of the bulk volume of the titanium-aluminum-based superalloy;

[0038] The material of the titanium alloy powder is Ti2AlNb or Ti-Al-Fe;

[0039] Step two, heat explosion mold preparation

[0040] The thermal explosion mold used for the thermal explosion reaction is composed of two parts: the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com