Single-cycle detection and protection method for peak current of brushless direct current motor

A brush DC motor, peak current technology, applied in the direction of emergency protection circuit devices, electrical components, etc., can solve the problems that can not truly reflect the peak current of the motor, overcurrent protection lag, protection does not burn the controller in time, etc., to achieve strong real-time performance , Improving timeliness and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

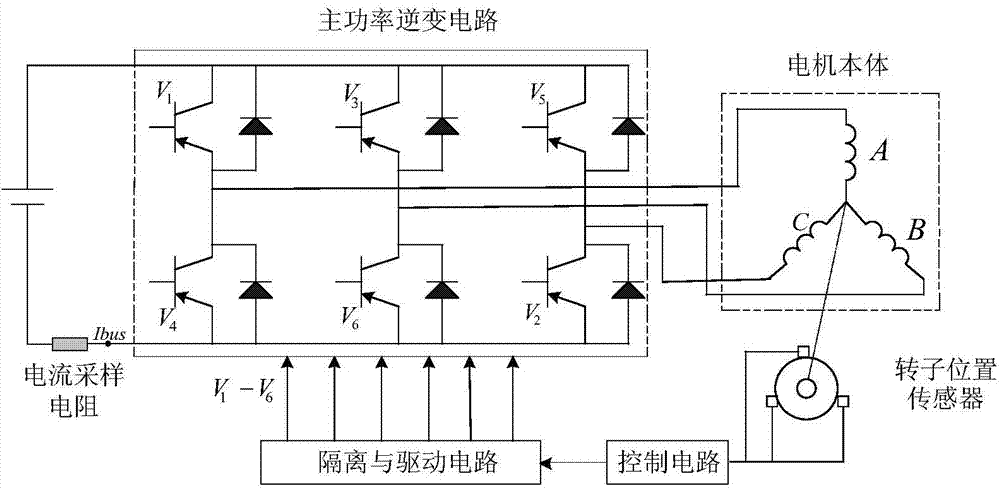

[0034] In the three-phase six-state brushless DC motor bus current detection circuit, the motor bus current passes through the power sampling resistor to convert the current value into a voltage value (see figure 1 ), and then sent to the AD port of DSP for detection after filtering and amplifying. It is especially emphasized that the filtering here only filters out the high-frequency clutter above the chopping frequency.

[0035] The control cycle of the control system software is 25uS (40KHz), the PWM chopping frequency is 25KHz, and the DSP uses TI's TMS320F2808.

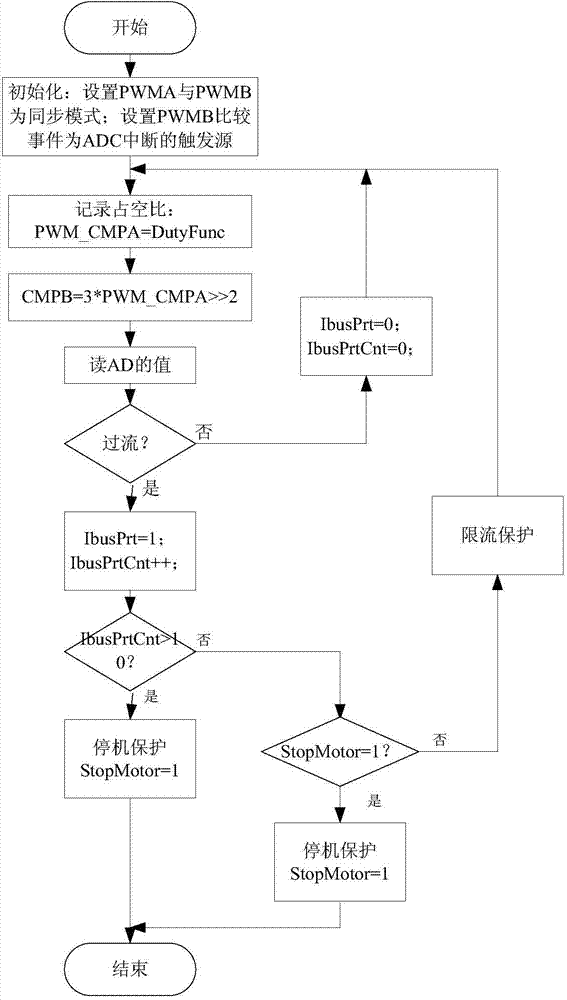

[0036] The specific implementation of current sampling and protection method is according to image 3 shown in the flowchart.

[0037] Step 1: In the initialization of the system control software, record the value of the initial duty ratio: PWM_CMPA=DutyFunc; set the A-way PWM and B-way PWM to sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com