Preparation method of fuel cell membrane electrode catalyst layer

An electrode catalytic layer, fuel cell membrane technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of increasing the complexity of the membrane electrode preparation process and production cost, which is not conducive to the efficient production of membrane electrodes, etc. Small changes and the effect of reducing mass transfer loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

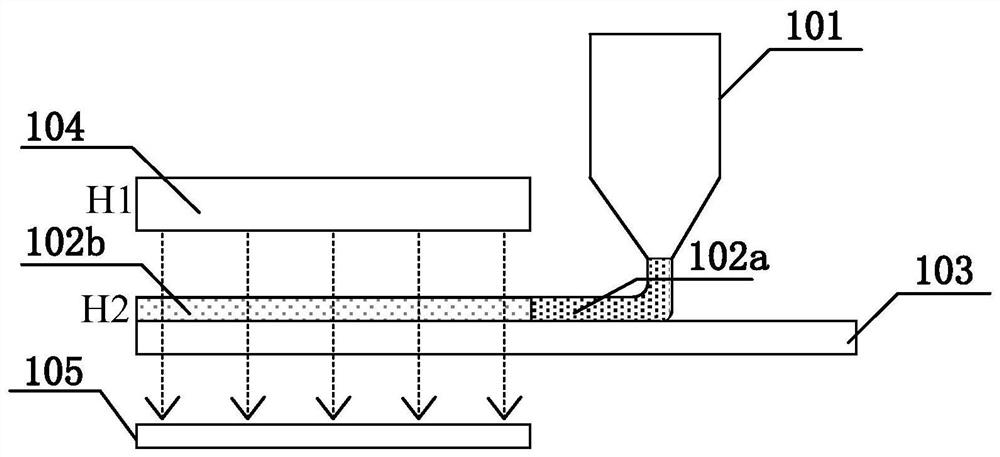

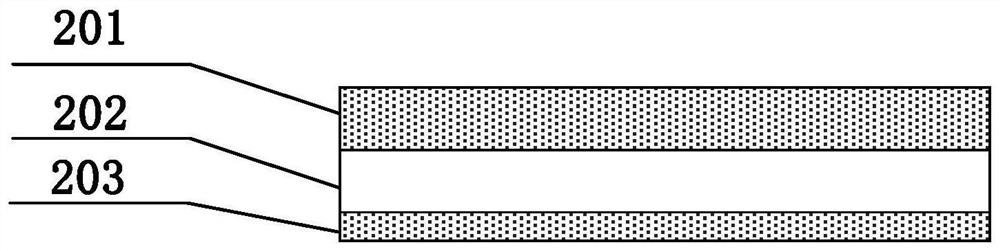

[0041] This embodiment provides a kind of preparation method of fuel cell membrane electrode catalytic layer, and makes the catalytic layer / ion exchange membrane module (Catalyst Coated Membrane, CCM) with uniform catalytic layer structure such as figure 2 As shown, the magnetic field control process device diagram of the catalytic layer drying process is shown in figure 1 Shown, the preparation method of CCM specifically comprises the following steps:

[0042] Step 1: get the mass fraction of 20g platinum (Pt) and be the PtCo / C catalyst of 50%, add 22g deionized water, 28g isopropanol and 50g mass fraction and be the Nafion solution of 20%, after magnetic stirring 4 hours, transfer to high pressure homogenization Carry out secondary dispersion in the homogenizer, the valve pressure of the high-pressure homogenizer is 300-500bar, the nozzle pressure is 400-600bar, disperse for 1 hour, and obtain the catalytic layer slurry; wherein, the atomic ratio of Pt and Co in the PtCo / C ...

Embodiment 2

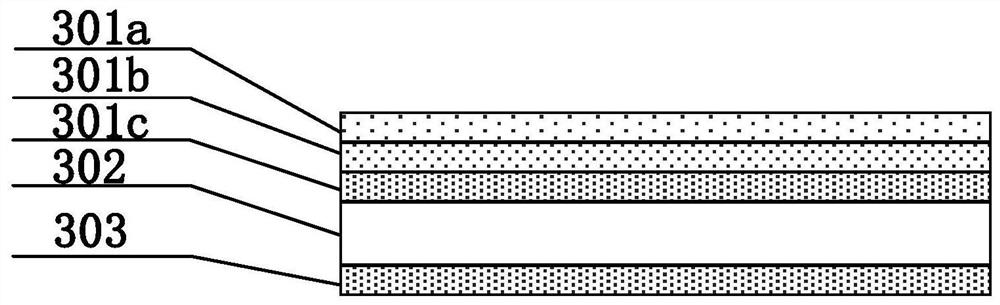

[0048] The present embodiment provides a kind of preparation method of fuel cell membrane electrode catalytic layer, and makes the catalytic layer / ion exchange membrane assembly (CCM) that has three-layer structure cathode catalytic layer such as image 3 As shown, the CCM specifically includes the following steps:

[0049] Step 1: get 20g platinum (Pt) mass fraction and be 50% PtCo / C catalyst, add 200g deionized water and 350g isopropanol, add 200g mass fraction after ultrasonic dispersion 5 minutes and be 5% Nafion solution, ultrasonic dispersion 20 minutes, then stirred for 1 hour to prepare catalyst slurry; wherein, the atomic ratio of Pt and Co in the PtCo / C catalyst was 3:1;

[0050] Step 2: Use an ultrasonic sprayer to spray the cathode catalytic layer: set the temperature of the bottom plate of the sprayer to 60°C, set the slurry flow rate and travel speed of the nozzle so that the single-layer Pt loading is 0.1mg / cm 2 ;An electromagnet is placed behind the nozzle thr...

Embodiment 3

[0056] This embodiment provides a method for preparing a catalytic layer of a fuel cell membrane electrode, which specifically includes the following steps:

[0057] Step 1: Take 15g of Pt / C catalyst with a mass fraction of platinum of 50%, 5g of PtCo / C catalyst with a mass fraction of platinum of 50%, add 200g of deionized water and 350g of isopropanol, and add after ultrasonic dispersion for 5 minutes 200g of Nafion solution with a mass fraction of 5%, ultrasonically dispersed for 20 minutes, and then stirred for 1 hour to prepare a catalyst slurry; wherein, the atomic ratio of Pt to Co in the PtCo / C catalyst was 3:1;

[0058] Step 2: Use an ultrasonic sprayer to spray the catalyst slurry on both sides of the Gore-select proton exchange membrane 602, set the temperature of the bottom plate heated by the sprayer to 60°C, and control the Pt loading by setting the slurry flow rate and travel speed of the sprayer. CCM was obtained after drying, wherein the Pt loading of the cath...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com