Combustible poison coating layer-containing coated fuel particle, pellet, fuel element, and preparation method of coated fuel particle

A technology for coating fuel particles and cladding layers, which is applied in the direction of reactor fuel materials, climate sustainability, and reduction of greenhouse gases. Widespread, enhanced neutron economy and safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

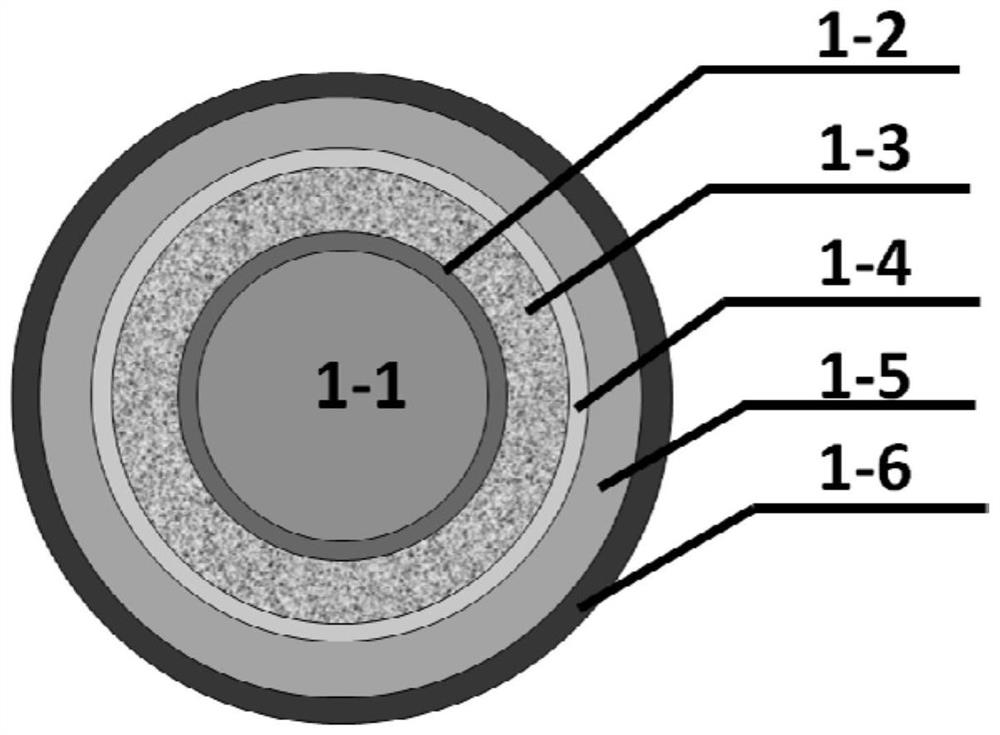

[0055] 1. A coated fuel particle containing a burnable poison coating:

[0056] The schematic diagram of the coated fuel particles is as figure 1 as shown, figure 1 Among them, 1-1 is the nuclear fuel core, 1-2 is the zirconium boride coating layer, 1-3 is the pyrolytic carbon loose layer, 1-4 is the inner transition layer of pyrolytic carbon, and 1-5 is the silicon carbide coating Layers, 1-6 are pyrolytic carbon environmental protection layers;

[0057] The coated fuel particles use ceramic fuel as the core, and the ceramic fuel core is sequentially coated with a zirconium boride coating layer, a loose layer, an inner transition layer, a carbide coating layer and an environmental protection layer;

[0058] The material composition of the ceramic fuel core is uranium dioxide, and the ceramic fuel core is a sphere with a diameter of 500-600 μm;

[0059] The thickness of the zirconium boride cladding layer is 1-2 μm;

[0060] The material composition of the loose layer is...

Embodiment 2

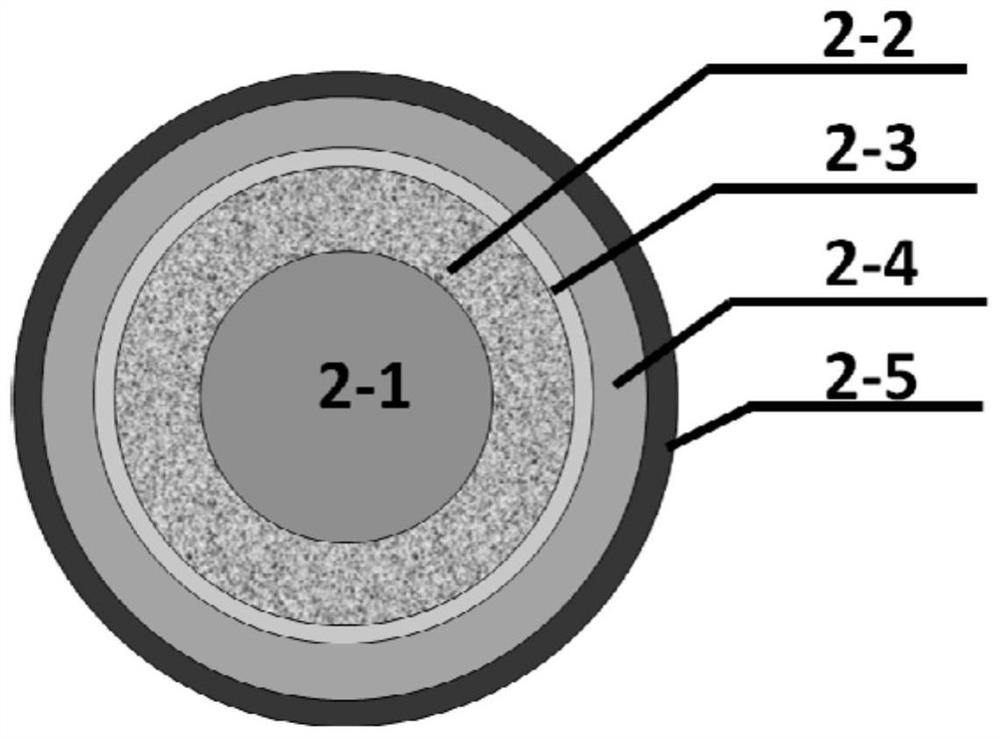

[0073] 1. A coated fuel particle containing a burnable poison coating:

[0074] The schematic diagram of the coated fuel particles is as figure 2 as shown, figure 2 Among them, 2-1 is the nuclear fuel core, 2-2 is the boron-containing pyrolytic carbon loose layer, 2-3 is the silicon carbide inner transition layer, 2-4 is the silicon carbide cladding layer, and 2-5 is the silicon carbide environmental protection layer. Floor;

[0075] The coated fuel particles use ceramic fuel as the core, and the ceramic fuel core is coated with a boron-containing loose layer, an inner transition layer, a carbide coating layer and an environmental protection layer in sequence;

[0076] The material composition of the ceramic fuel core is uranium nitride, and the ceramic fuel core is a sphere with a diameter of 800-900 μm;

[0077] The boron-containing loose layer is based on pyrolytic carbon, the porosity of the loose layer is 50%, the boron content is 5%, and the thickness is 90-100 μm; ...

Embodiment 3

[0089] A coated fuel particle containing a burnable poison coating layer, the coated fuel particle is the same as in Example 2, the difference is that 2-2 is a boron-containing silicon carbide loose layer, and the boron-containing loose layer uses silicon carbide as a matrix, The porosity of the loose layer is 50%, the boron content is 5%, and the thickness is 90-100 μm; wherein, the preparation method of the boron-containing silicon carbide loose layer comprises the following steps:

[0090] Heat the temperature of the fluidized bed to 1430°C, use argon as the carrier gas, pass through methyltrichlorosilane, the flow rate of argon is 15.0L / min, and pass through BCl at the same time 3 , BCl 3 The flow rate is 0.5 L / min, and the reaction time is 10 minutes to obtain a boron-containing silicon carbide loose layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com