A photocatalytic reduction of co 2 Method and application of pickering microbubble system for preparing methanol

A construction method and CO2 technology, applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problems of low reduction efficiency and poor selectivity of target products, improve reduction efficiency, solve contact difficulties, increase Effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

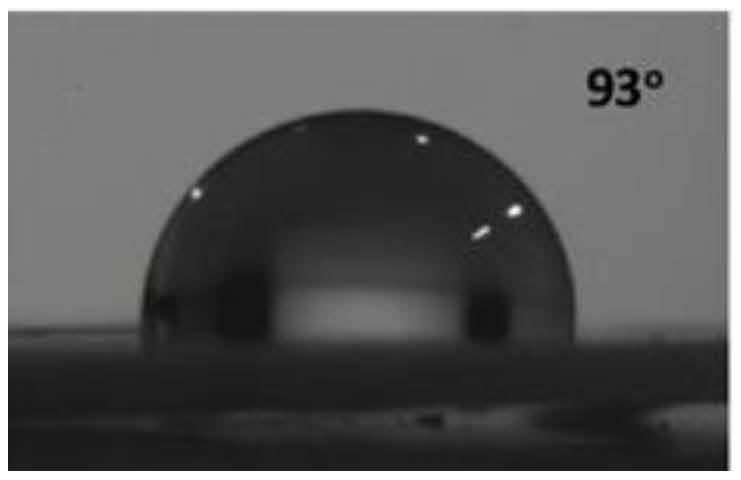

[0035] According to attached figure 1 The method shown to prepare the amphiphilic Pickering photocatalyst: the porous SiO 2 Surface hydroxylation of microspheres to obtain hydrophilic SiO 2 (see attached figure 2 , its gas / liquid / solid three-phase contact angle is 24 ° ), then regiomodified by hydrophobic aminosilicone esters to become amphiphilic SiO 2 carrier (see attached image 3 , its gas / liquid / solid three-phase contact angle is 93 ° ); the metal photocatalyst Pt was supported on amphiphilic SiO by photoreduction method 2 carrier to obtain amphiphilic Pickering photocatalyst.

[0036] Construction of the Pickering microbubble system: Weigh 1.0 g of amphiphilic Pickering photocatalyst, add it to a closed light-transmitting reactor containing 30 mL of deionized water, and fill it with CO 2 Gas and maintain the system pressure at 0.1MPa, stir magnetically at 800rpm for 10min to form CO in water 2 Type Pickering microbubble system (see Figure 4). attached Figure ...

Embodiment 2

[0038] Preparation of amphiphilic Pickering photocatalysts: Surface introduction of porous carbon materials-N + (CH 3 ) 3 Cl - The group is treated with hydrophilicity, and then adjusted with hydrophobic silane to obtain a gas / liquid / solid three-phase contact angle of 89 ° amphiphilic support; the TiO 2 The photocatalyst is loaded on the amphiphilic carrier to obtain the amphiphilic Pickering photocatalyst.

[0039] Construction of the Pickering microbubble system: Weigh 1.5g of amphiphilic Pickering photocatalyst, add it to a closed light-transmitting reactor containing 50mL deionized water, and fill it with CO 2 Gas and maintain the system pressure at 0.2MPa, stir magnetically at 900rpm for 15min to form CO in water 2 Type Pickering microbubble system.

Embodiment 3

[0041] Preparation of amphiphilic Pickering photocatalyst: introduce -COOH and -OH groups on the surface of graphene for hydrophilic treatment, and then use hydrophobic silicone grease to control, and obtain a gas / liquid / solid three-phase contact angle of 89 ° amphiphilic carrier; protonated g-C by electrostatic self-assembly method 3 N 4 The photocatalyst is loaded on the amphiphilic carrier to obtain the amphiphilic Pickering photocatalyst.

[0042] Construction of the Pickering microbubble system: Weigh 1.8g of amphiphilic Pickering photocatalyst, add it to a closed light-transmitting reactor containing 60mL deionized water, and fill it with CO 2 Gas and maintain the system pressure at 0.25MPa, and magnetically stir at 1000rpm for 20min to form CO in water 2 Type Pickering microbubble system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com