Instantaneous pressure-relief spinning method based high polymer fiber, preparation method thereof and application

A high polymer fiber and high polymer technology, applied in fiber processing, rayon manufacturing, fiber chemical characteristics, etc., can solve the problems of controllable fiber shape, large solvent pollution, etc., achieve good wear resistance and avoid recycling and treatment, high vapor permeability and barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1 Preparation method of polyethylene micro-nano fibers based on instantaneous pressure release spinning method

[0040] This embodiment is carried out according to the following sequence of steps:

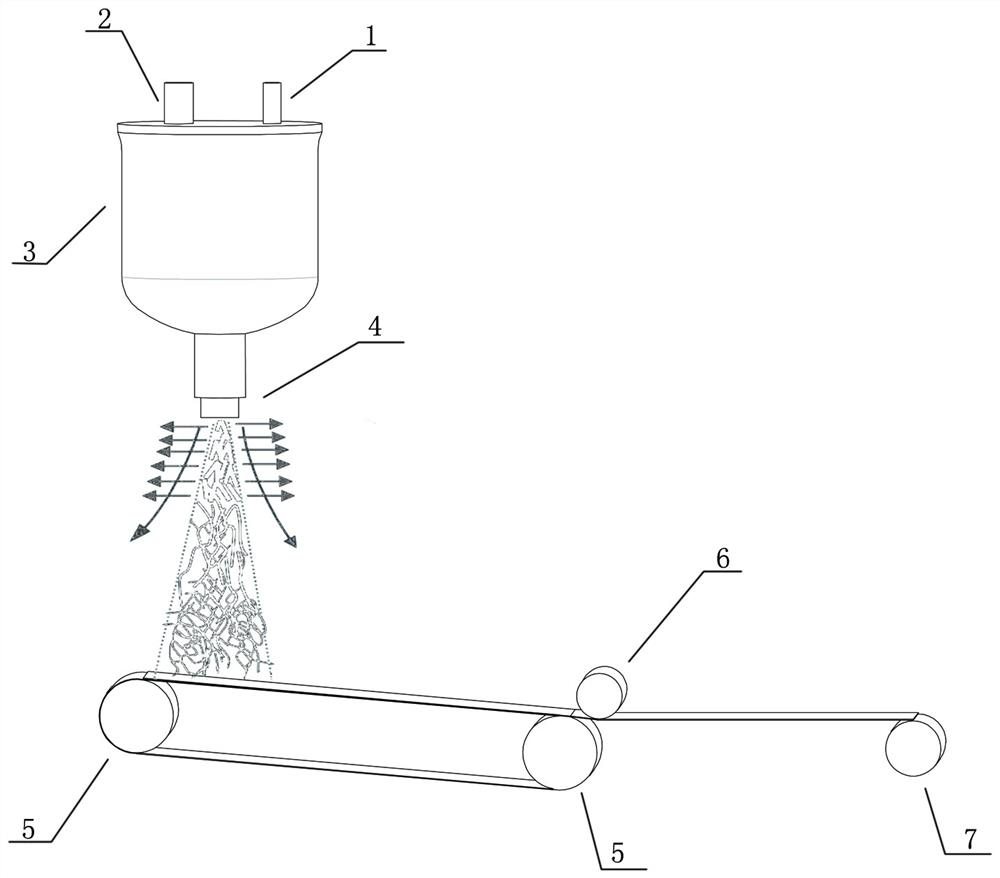

[0041] One, such as figure 1 As shown, 90kg of high-density polyethylene and 10kg of plasticizer cyclohexane are metered and transported from raw material port 2 to 150 o In C supercritical kettle 3, import supercritical carbon dioxide to 18MPa from supercritical gas inlet 1 under agitation state, form supercritical spinning fluid after being stable for 2h;

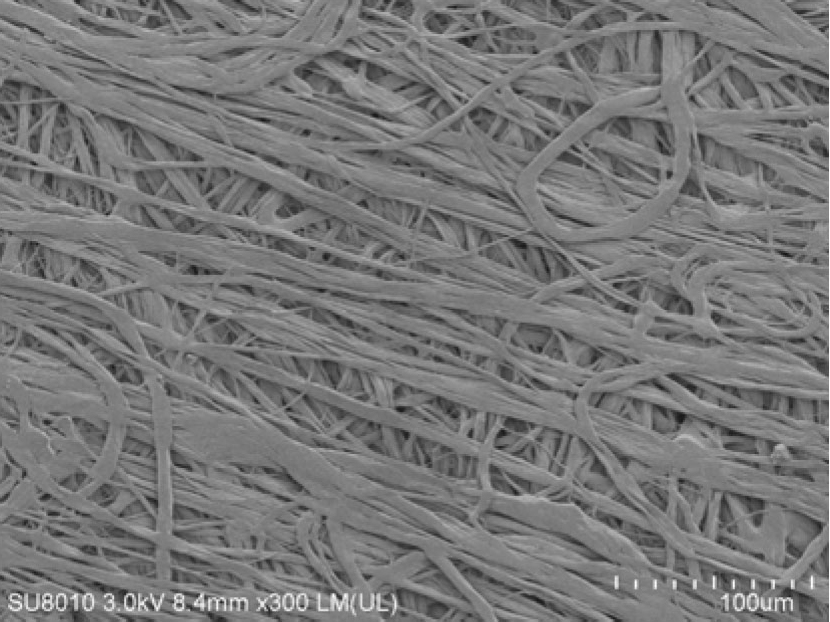

[0042] 2. In the open air environment where the supercritical spinning fluid is instantaneously released through a circular nozzle at a speed of 200m / s, the supercritical spinning fluid undergoes phase phase rapidly from the supercritical state under the high pressure difference of 150 produced by the air amplifier 4. Separation and conversion into carbon dioxide gas, cyclohexane gas and solidified high-densit...

Embodiment 2

[0045] Example 2 Preparation method of polyamide 6 micro-nano fibers based on instant pressure release spinning method

[0046] This embodiment is carried out according to the following sequence of steps:

[0047] One, such as figure 1 As shown, 70 kg of polyamide 6 slices, 15 kg of plasticizer isopropanol and 15 kg of dichloromethane are metered and transported from raw material port 2 to 130 oIn C supercritical kettle 3, import supercritical carbon dioxide to 12MPa from supercritical gas inlet 1 under stirring state, form supercritical spinning fluid after being stable for 3h;

[0048] 2. In the open air environment where the supercritical spinning fluid is instantaneously released through a circular nozzle at a speed of 250m / s, the supercritical spinning fluid undergoes rapid phase phase from the supercritical state under the high pressure difference of 180 produced by the air amplifier 4. Separation and conversion into carbon dioxide gas, isopropanol gas, dichloromethane...

Embodiment 3

[0050] Example 3 Preparation method of polylactic acid micro-nano fibers based on instantaneous pressure release spinning method

[0051] This embodiment is carried out according to the following sequence of steps:

[0052] One, such as figure 1 As shown, 95kg of polylactic acid slices and 5kg of plasticizer dioxane are measured and transported from raw material port 2 to 110 o In C supercritical kettle 3, import supercritical carbon dioxide to 8MPa from supercritical gas inlet 1 under stirring state, form supercritical spinning fluid after being stable for 2h;

[0053] 2. In the open air environment where the supercritical spinning fluid is instantaneously released through a circular nozzle at a speed of 200m / s, the supercritical spinning fluid undergoes phase phase rapidly from the supercritical state under the high pressure difference of 100 produced by the air amplifier 4. Separation and conversion into carbon dioxide gas, dioxane gas and cured polylactic acid. In the ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com