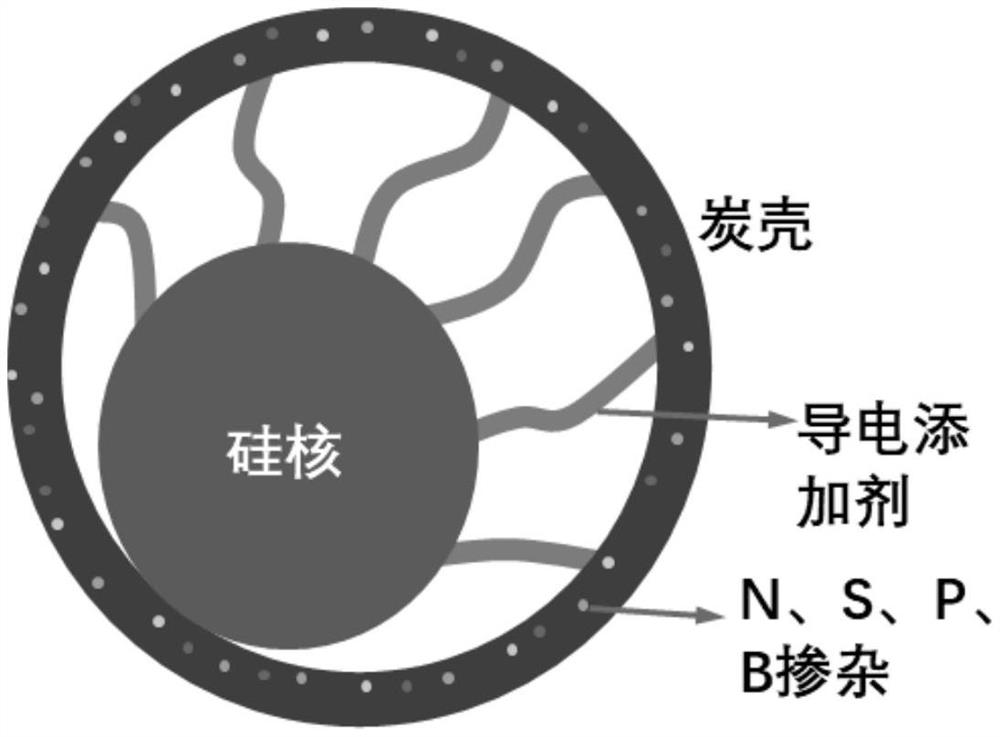

Multi-heteroatom co-doped carbon shell coated silicon composite material and preparation method thereof

A composite material and a heteroatom technology, which is applied to the composite material and the preparation field of multi-heteroatom co-doped carbon shell-coated silicon, can solve the problems of low reversible capacity, unsatisfactory cycle stability, etc. The effect of improving transport and diffusion rates and ensuring structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

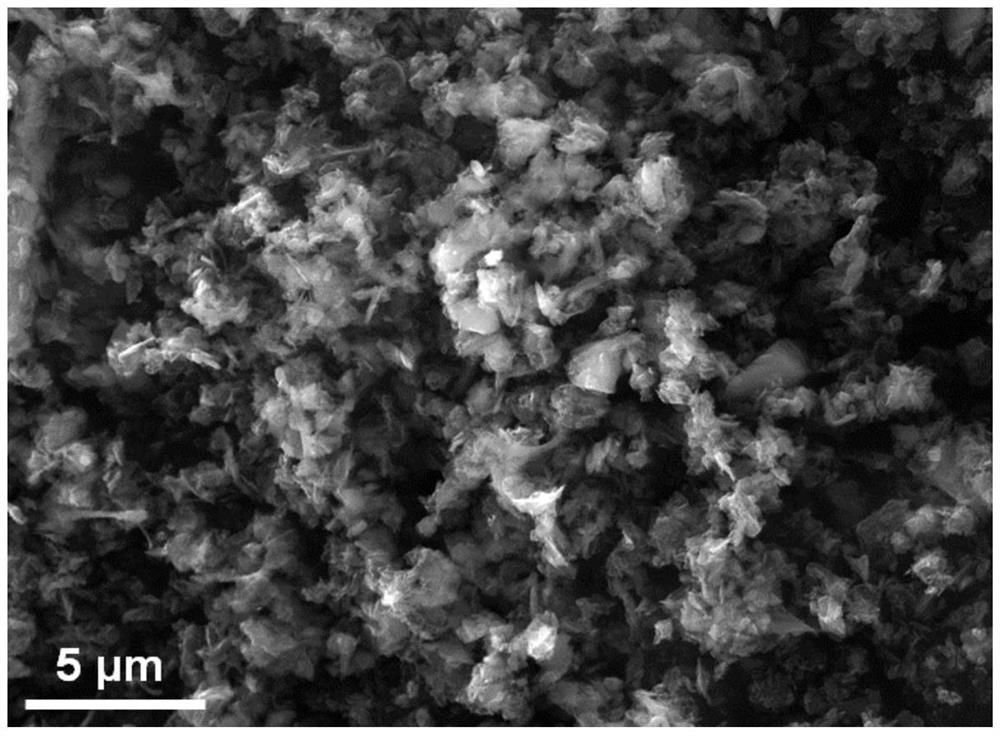

Image

Examples

Embodiment 1

[0035] (1) Pretreatment of carbon precursor: Weigh 2g of medium-temperature pitch, grind it into powder in a mortar, pour it into a conical flask containing 50ml of toluene solution, and stir for 20min; then weigh 2g of melamine, 1g of sublimated sulfur, 0.5g of sodium tetraphenylborate and 1g of red phosphorus were added to the above solution in turn, ultrasonicated for 10 minutes, and then evaporated to dryness while stirring to obtain a medium temperature pitch mixed with nitrogen source, sulfur source, boron source and phosphorus source.

[0036] (2) Oxidation treatment of silicon powder: put industrial silicon powder and water into a ball mill tank at a mass ratio of 1:1, pass in argon gas protection, and then perform high-energy ball milling at a speed of 1000r / min for 2 hours. The treated powder was transferred to a tube furnace and heated to 800 °C for 2 h under the protection of argon to obtain SiO 2 and Si mixture.

[0037] (3) Carbon coating treatment: doped pitch,...

Embodiment 2

[0042] (1) Pretreatment of carbon precursor: Weigh 2g of medium-temperature pitch, grind it into powder in a mortar, pour it into a conical flask containing 50ml of toluene solution, and stir for 20min; then weigh 2g of melamine, 1g of thiourea, 0.5 g of boric acid was added to the above solution in turn, ultrasonically treated for 10 min, and then evaporated to dryness while stirring to obtain a medium-temperature pitch mixed with nitrogen source, sulfur source and boron source.

[0043] (2) Oxidation treatment of silicon powder: put industrial silicon powder and water into a ball mill tank at a mass ratio of 1:0.5, pass in argon gas protection, and then perform high-energy ball milling treatment at a speed of 1000r / min for 3 hours. The treated powder was transferred to a tube furnace and heated to 800 °C for 2 h under the protection of argon to obtain SiO 2 and Si mixture.

[0044] (3) Carbon coating treatment: doped pitch, SiO 2 / Si mixture and conductive carbon black are...

Embodiment 3

[0048] (1) Pretreatment of carbon precursor: Weigh 2g of phenolic resin, grind it into powder in a mortar, pour it into a conical flask containing 50ml of ethanol solution, and stir for 20min; then weigh 2g of urea, 1g of ethylphosphonic acid Sequentially added to the above solution, treated with ultrasound for 10 minutes, and then evaporated to dryness while stirring to obtain medium-temperature asphalt mixed with nitrogen source and phosphorus source.

[0049] (2) Oxidation treatment of silicon powder: put industrial silicon powder and water into a ball mill tank at a mass ratio of 1:3, pass through argon protection, and then perform high-energy ball milling at a speed of 1000r / min for 4 hours. The treated powder was transferred to a tube furnace and heated to 800 °C for 2 h under the protection of argon to obtain SiO 2 and Si mixture.

[0050] (3) Carbon coating treatment: the doped phenolic resin, SiO 2 / Si mixture and graphene are packed in the ball mill jar according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com