Surface grafted curcumin modified degradable polyurethane composite material as well as preparation method and application thereof

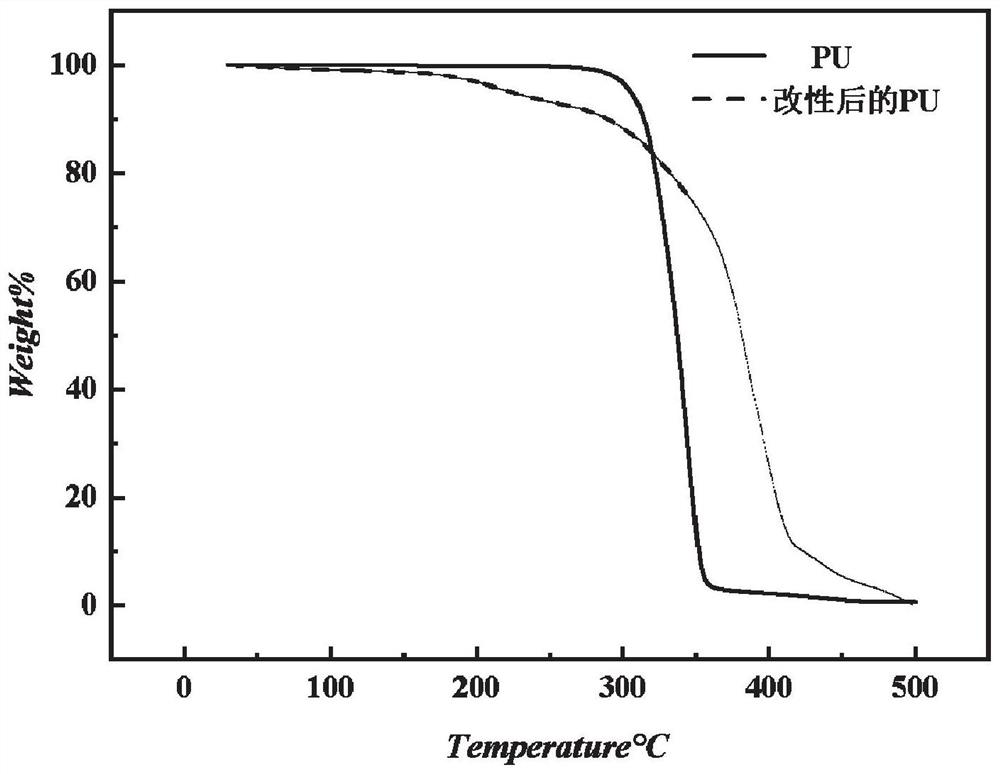

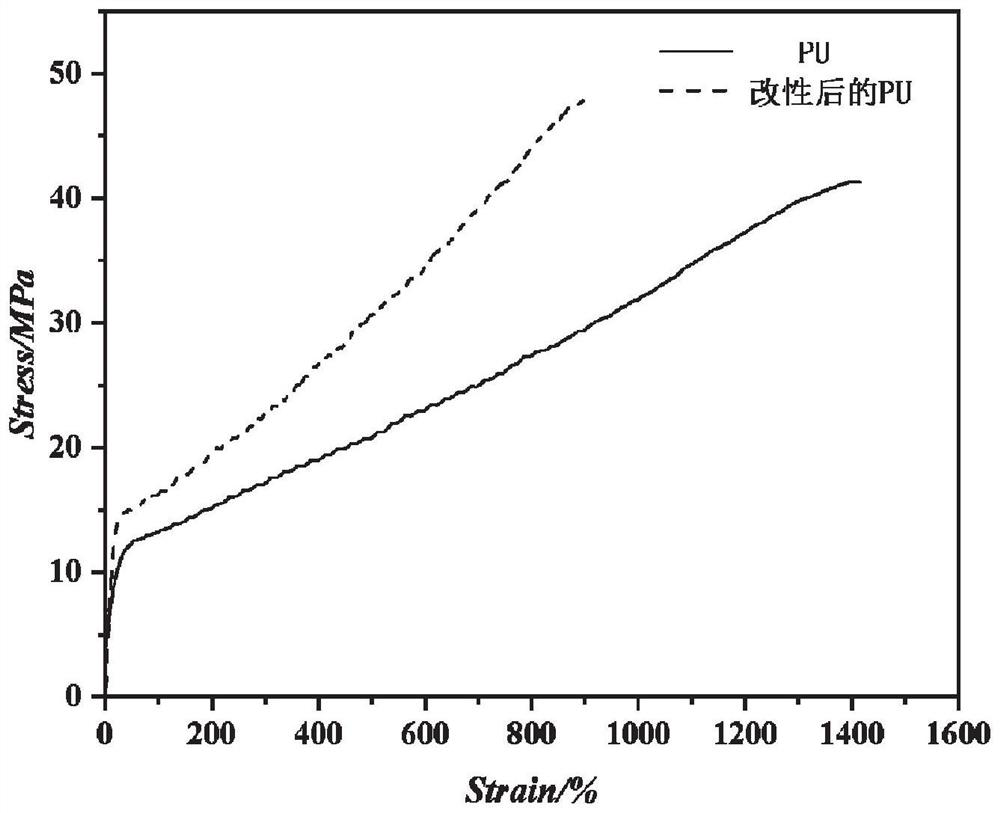

A polyurethane material and surface grafting technology are applied in the field of surface grafting curcumin-modified degradable polyurethane composite materials and their preparation fields, which can solve the problems of single additional properties and the like, and achieve stable fluorescence, mechanical properties and thermal stability improvement. , good antibacterial and biocompatibility effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] (1) Take 0.5mL hexamethylene diisocyanate (HDI) and add it to 10mL anhydrous toluene, put 1×1cm 2 After the modified polyurethane material is washed with anhydrous toluene until the surface is clean, it is put into the mixed solution of anhydrous toluene and hexamethylene diisocyanate (HDI), and 1-2 drops of the catalyst dibutyltin dilaurate are added dropwise. Shake the reaction at ℃ for 2 hours. After the completion, take out the membrane and wash it repeatedly to remove unreacted HDI, and prepare a membrane (PU-NCO) grafted with isocyanate on the surface of polyurethane;

[0058] (2) Dissolve 0.368g curcumin in 10mL of anhydrous toluene solution, then mix the PEU-NCO membrane prepared in step (1) with the above solution, stir and react at 45°C for 16h, and then use anhydrous toluene Rinse (measure the washing liquid), and then rinse with ethanol, and put it into a vacuum drying oven to dry for 24 hours to prepare a degradable polyurethane film modified by grafting cu...

Embodiment 2

[0064] (1) 0.368g of curcumin, 0.2g of 2-(-4-isobutylphenyl)propionic acid (ibuprofen), 0.2g of 1-ethyl-(3-dimethylaminopropyl ) carbodiimide hydrochloride (EDC.HCL), 0.12g of 4-dimethylaminopyridine (DMAP) were added to 15mL of dichloromethane and mixed respectively, stirred and reacted at 25°C for 1.5h, and cooled with NaHCO 3 Extracted from dichloromethane, then subjected to Na 2 SO 4 Drying, concentration under reduced pressure, purification by silica gel chromatography, and drying to obtain the pure product modified curcumin;

[0065] (2) Take 0.5mL hexamethylene diisocyanate (HDI) and add it to 10mL anhydrous toluene, put 1×1cm 2 After the modified polyurethane material is washed with anhydrous toluene until the surface is clean, it is put into the mixed solution of anhydrous toluene and hexamethylene diisocyanate (HDI), and 1-2 drops of the catalyst dibutyltin dilaurate are added dropwise. Shake the reaction at ℃ for 2 hours. After the completion, take out the membr...

Embodiment 3

[0069] (1) 0.552g of curcumin, 0.4g of 2-(-4-isobutylphenyl)propionic acid (ibuprofen), 0.4g of 1-ethyl-(3-dimethylaminopropyl ) carbodiimide hydrochloride (EDC.HCL), 0.24g of 4-dimethylaminopyridine (DMAP) were added to 20mL of dichloromethane and mixed respectively, stirred and reacted at 25°C for 2h, and cooled with NaHCO 3 Extracted from dichloromethane, then subjected to Na 2 SO 4 Drying, concentration under reduced pressure, purification by silica gel chromatography, and drying to obtain the pure product modified curcumin;

[0070] (2) Take 0.8mL hexamethylene diisocyanate (HDI) and add it to 15mL anhydrous toluene, put 1×1cm 2 After the modified polyurethane material is washed with anhydrous toluene until the surface is clean, put it into the mixed solution of anhydrous toluene and hexamethylene diisocyanate (HDI), add 1-2 drops of catalyst DBTDL, and shake it at 45°C for 4 hours. After the completion, take out the membrane and wash it repeatedly to remove unreacted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com