Blast belt type roasting machine and method for roasting pellets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

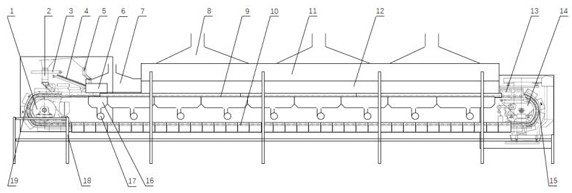

[0030] Such as figure 1 Shown, a blast belt roaster. The head star wheel 1 of the roasting machine is driven by a transmission device. The head curve 19 is installed with the upper track 9 and the lower track 10 and fixed on the frame 18, and the tail curve 15 and the tail star wheel 14 are fixedly connected On the tail star wheel swing frame, on the upper track 9, starting from the machine head, set the bottoming chute 2 and the bottoming valve under the chute, the wide belt conveyor 3, the roller screen distributor 4 and the collecting belt located below. Machine, paving chute 5, exhaust gas exhaust and smoke collecting furnace cover 7 and movable door 6, waste heat power generation boiler 11, furnace cover 12 (the furnace cover is the boiler hearth, and the interior is built with lightweight high-temperature alumina hollow ball insulation bricks) And the exhaust gas exhaust fume collecting hood 8 above the boiler, the wind box 16 and the blower 17 below the wind box under th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com