Amino-modified unsaturated polyester resin

A polyester resin and amino modification technology, applied in the direction of adhesive additives, polymer adhesive additives, adhesives, etc., can solve the problems of partial brittleness of product performance, low adhesive force, and limited development, etc., to achieve the solution of bonding The effect of poor force, improved adhesion, and improved flexibility and adhesive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

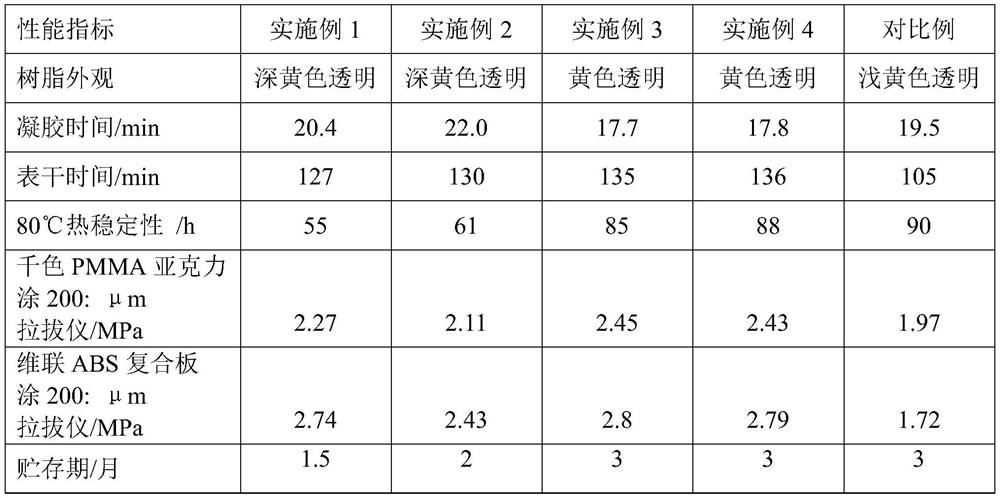

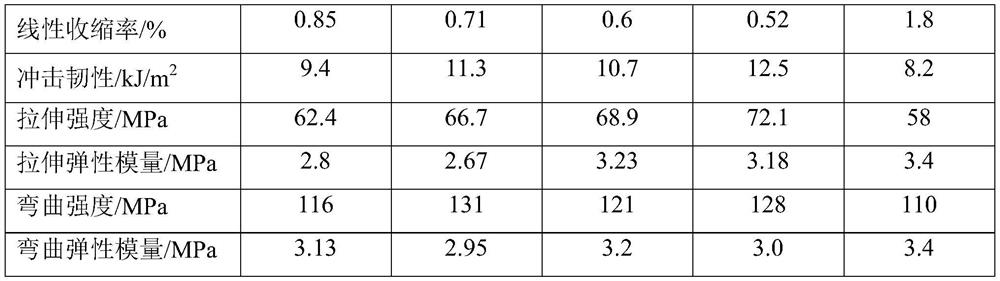

Examples

Embodiment 1

[0026] Add 8.5 mol of propylene glycol, 0.78 mol of melamine, 4.76 mol of phthalic anhydride, 3.1 mol of maleic anhydride, 0.1 g of methylhydroquinone, and reflux reaction at 100-200°C until the acid value is less than 30 mgKOH / g , cooling down to 150°C, adding 0.2 grams of methyl hydroquinone, then cooling down to 70-100°C, adding 7.2mol styrene for dilution, 0.1 grams of p-tert-butylcatechol, and 1 gram of paraffin wax, to obtain amino-containing unsaturated resin .

Embodiment 2

[0028] Add 2.7 mol propylene glycol, 5.8 mol ethylene glycol, 1 mol diethylene glycol, 0.7 mol urea, 6.57 mol phthalic anhydride, 2.2 mol maleic anhydride, 0.1 g of methyl hydroquinone, at 100-200 °C Reflux reaction within the range until the acid value is less than 30mgKOH / g, cool down to 150°C and add 0.2g of methyl hydroquinone, then cool down to 70-100°C and add 7.5mol styrene for dilution, 0.1g of p-tert-butylcatechol , 1 gram of paraffin to obtain an amino-containing unsaturated resin.

[0029] Prioritize the reaction of urea with phthalic anhydride at 135-145°C until the acid value is in the range of 120-150mgKOH / g, and then add maleic anhydride to react.

Embodiment 3

[0031] Add 6.8 mol of methylpropanediol, 2.2 mol of ethylene glycol, 5.8 mol of phthalic anhydride, 2.5 mol of maleic anhydride, 0.1 g of methyl hydroquinone, and reflux in the range of 100-200°C until the acid value Less than 30mgKOH / g, cool down to 150°C and add 0.2g of methyl hydroquinone, then cool down to 70-100°C and add 7.2mol styrene to dilute, 0.1g of p-tert-butylcatechol to obtain carboxyl-terminated unsaturated resin, Cool down to 55-70°C, add 0.35mol urethane acrylic acid to react for 1 hour, and add 1 gram of paraffin to obtain amino group-containing unsaturated polyester resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com