A kind of method for adjusting polyglycolic acid molecular chain structure

A polyglycolic acid and molecular chain technology, applied in the field of molecular chain regulation, can solve problems such as slow degradation rate, difficulty in obtaining transparent molded products, and difficulty in amorphous preformed products, etc. Hydrolysis performance, effect of improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Preparation of polyglycolic acid polymer with anti-hydrolysis and anti-oxidation properties: under the atmosphere of normal temperature and pressure and nitrogen protection, add 100g of glycolide monomer, 100ppm of isopropanol, 20ppm of linear stannate, open and stir, from 80 The temperature rises at ℃ and the reaction time is 100min. SAG (epoxy polymer) is added 5min before the end of the reaction, preferably in the form of a liquid to facilitate dispersion.

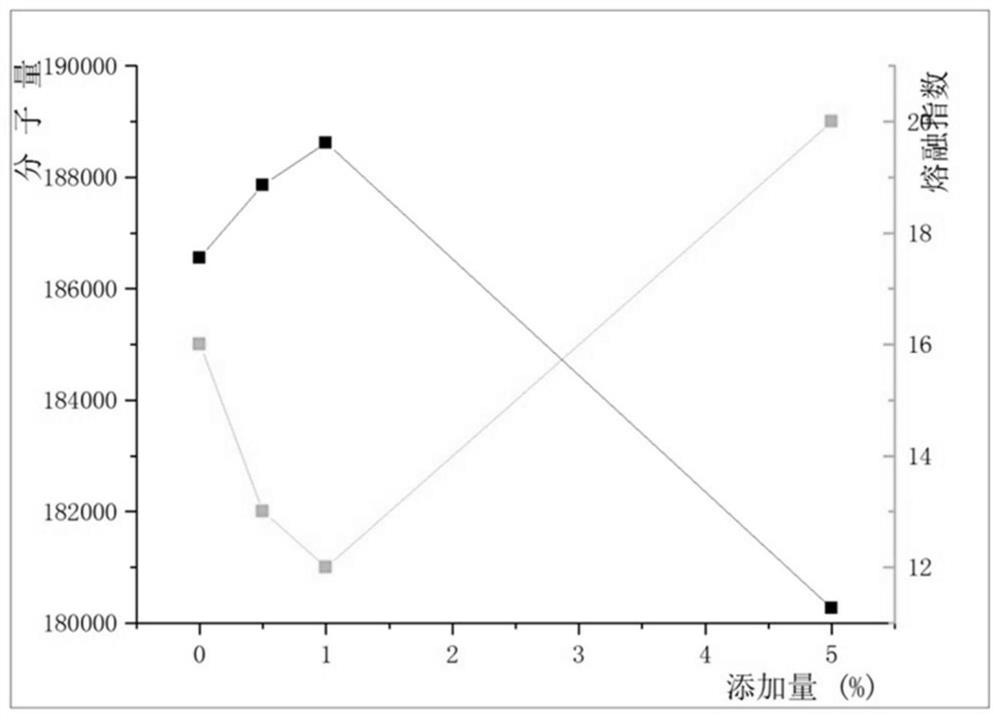

[0064] figure 1 By adding different amounts of SAG epoxy polymer, the final product molecular weight and material fluidity change. It can be seen from the figure that the molecular weight will increase when the addition amount is from 0 to 1%, and the melt index will become smaller at the same time. The reaction between the epoxy polymer and the chain end leads to a slight increase in its molecular weight and is affected by the end-capping effect of the polyester. The anti-oxidation performance has improved, and...

Embodiment 2

[0069] Preparation of polyglycolic acid polymer with increased molecular weight: under the atmosphere of normal temperature and pressure and nitrogen protection, add 100g of glycolide monomer, 100ppm of isopropanol, 12ppm of linear stannate, turn on and stir, and start the heating reaction from 80°C After reaching the reaction temperature, PEG with different molecular weights and Wt accounting for 5% was added to react, and the reaction was continued for 50 min after reaching the reaction temperature.

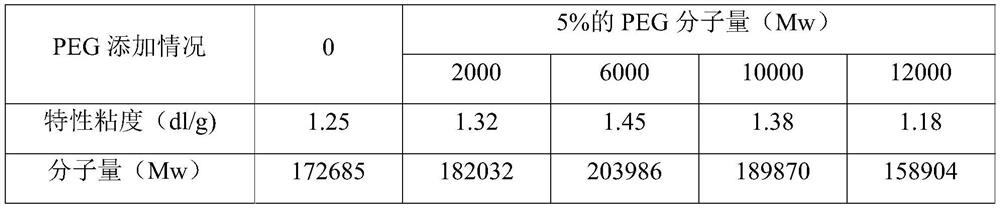

[0070] Table 2

[0071]

[0072] As can be seen from the above table, the molecular weight changes when 5% of PEG with different molecular weights are added. When PEG with a molecular weight of 6000 is added, the molecular weight of the polyester obtained increases by 3w compared with the pure material, and the intrinsic viscosity also increases accordingly.

Embodiment 3

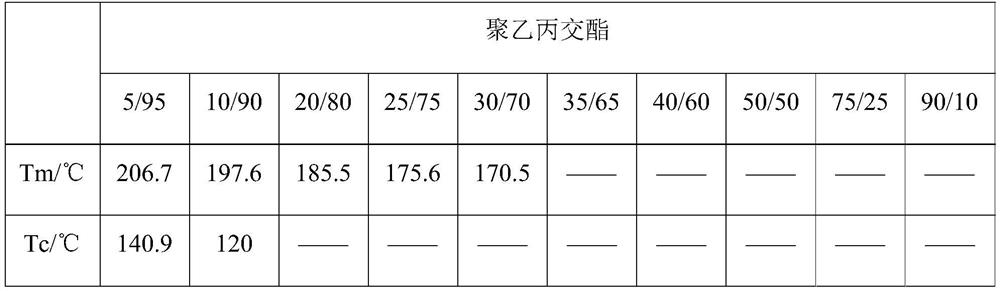

[0074] Preparation of non-crystalline polyglycolide: under the atmosphere of normal temperature and pressure and nitrogen protection, add 100g glycolide monomer, 82.5g lactide monomer, 100ppm isopropanol, 12ppm linear stannate, turn on and stir , start the heating reaction from 80℃, and react for 6 hours after reaching the target temperature, then devolatilize and then cool and granulate. The obtained sample is light yellow transparent crystal, the weight average molecular weight is 15×104, the intrinsic viscosity is 1.21dL / g, the tensile strength of polyglycolic acid is 100Mpa, the elongation is 3.15%, and the tensile strength of polyglycolide is 78Mpa, the elongation is 300%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com