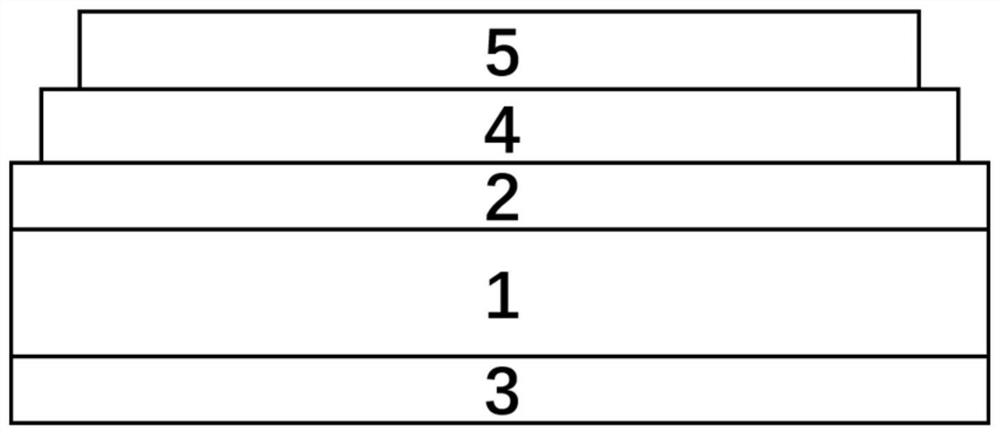

Graphene/single atomic layer gas/gaas radio generator and manufacturing method thereof

A single atomic layer, graphene layer technology, applied in circuits, electrical components, circuit devices, etc., can solve problems such as difficult preparation and large-scale integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) After making the first electrode (titanium gold) on the back of gallium arsenide, perform the following cleaning operation on the gallium arsenide chip: first use acetone to ultrasonically clean it for 5 minutes, then wash it three times with deionized water, and then use dilute hydrochloric acid solution to remove oxidation. layer, then wash off the dilute hydrochloric acid, and then oxidize the surface of gallium arsenide with hydrogen peroxide solution, repeat the deoxidation and oxidation operation 3-7 times, passivate the gallium arsenide sample with 18% ammonium sulfide solution, and finally use deionized water Cleaning is complete;

[0025] 2) Take a piece of copper-based graphene spin-coated with PMMA, and cut it into a regular shape of 0.5cm×0.5cm. Place the cut copper-based graphene on the upper surface of the copper foil etching solution. Use a glass slide to transfer the etched graphene+PMMA layer to deionized water for cleaning, and transfer and clean f...

Embodiment 2

[0029] 1) After making the first electrode (Ti / Au) on the back of GaAs, the gallium arsenide wafer is cleaned as follows: First, ultrasonically clean with acetone for 5 minutes, then wash with deionized water three times, and then remove with dilute hydrochloric acid solution Oxide layer, then wash off the dilute hydrochloric acid, then oxidize the surface of gallium arsenide with hydrogen peroxide solution, repeat the deoxidation and oxidation operation 3-7 times, passivate the gallium arsenide sample with 12% ammonium sulfide solution for 15 minutes, and finally use Deionized water cleaning is completed;

[0030] 2) Take a piece of copper-based graphene spin-coated with PMMA, and cut it into a regular shape of 0.5cm×0.5cm. Put the cut graphene on the copper foil in the copper foil etching solution (graphene face up). Use a glass slide to transfer the etched graphene+PMMA layer to deionized water for cleaning, and transfer and clean for 3-5 times;

[0031] 3) Transfer the c...

Embodiment 3

[0034] 1) After making the first electrode (Ti / Au) on the back of GaAs, the gallium arsenide wafer is cleaned as follows: First, ultrasonically clean with acetone for 5 minutes, then wash with deionized water three times, and then remove with dilute hydrochloric acid solution Oxide layer, wash off the dilute hydrochloric acid and then oxidize the surface of gallium arsenide with hydrogen peroxide solution, repeat the deoxidation and oxidation operation 3-7 times, passivate the gallium arsenide sample with 18% ammonium sulfide solution for 30 minutes, and finally use deionized Water cleaning is complete;

[0035] 2) Take a piece of copper-based graphene spin-coated with PMMA, and cut it into a regular shape of 0.5cm×0.5cm. Put the cut graphene on the copper foil in the copper foil etching solution (graphene face up). Use a glass slide to transfer the etched graphene+PMMA layer to deionized water for cleaning, and transfer and clean for 3-5 times;

[0036] 3) Transfer the clea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com