Nickel oxide/titanium dioxide nanorod composite structure gas sensor as well as preparation method and application thereof

A gas sensor, titanium dioxide technology, applied in nanotechnology, nanotechnology, nanotechnology for sensing, etc., can solve the problems of long response recovery time and low sensitivity, and achieve short response recovery time, high sensitivity and repeatability , Improve the effect of gas-sensing characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The present invention also provides a method for preparing the gas sensor described above, comprising the following steps:

[0048] (1) Prepare a titanium dioxide nanorod film on the surface of the substrate by hydrothermal method, and then carry out the first annealing;

[0049] (2) growing nickel oxide on the titanium dioxide nanorod film after the first annealing, and then performing the second annealing to obtain a nickel oxide / titanium dioxide nanorod composite structure layer;

[0050] (3) Preparing interdigitated electrodes on the surface of the nickel oxide / titanium dioxide nanorod composite structure to obtain a nickel oxide / titanium dioxide nanorod composite structure gas sensor.

[0051] The invention adopts a hydrothermal method to prepare a titanium dioxide nanorod thin film on the surface of a substrate, and then performs drying and first annealing in sequence. In the present invention, the substrate is preferably cleaned and dried before use; the cleanin...

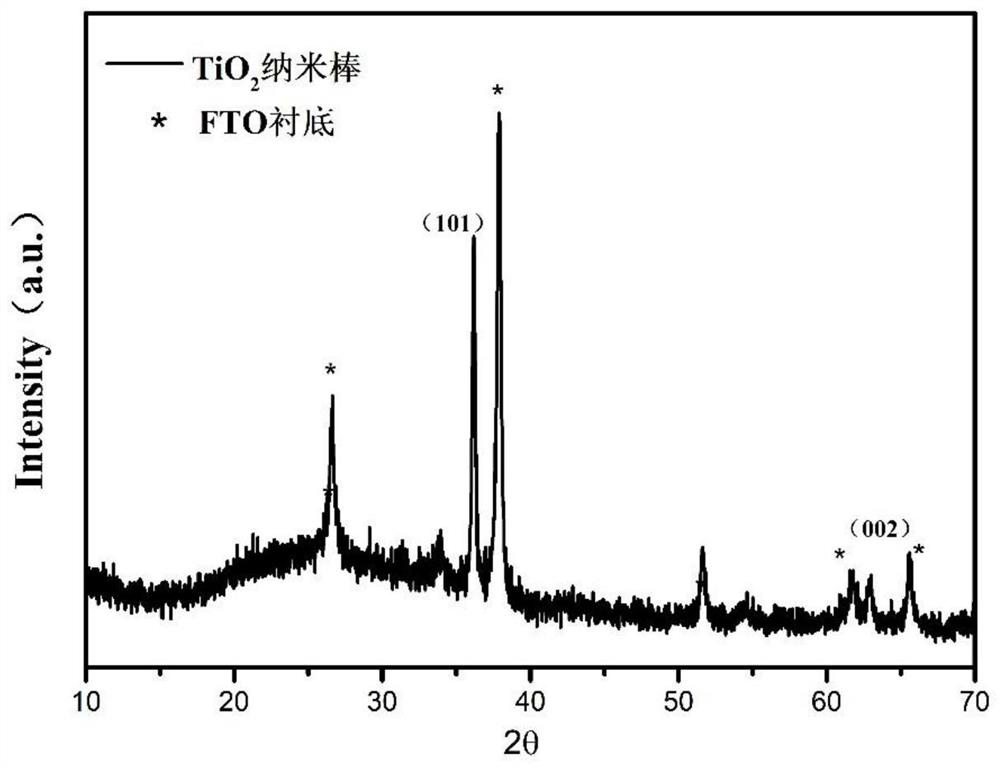

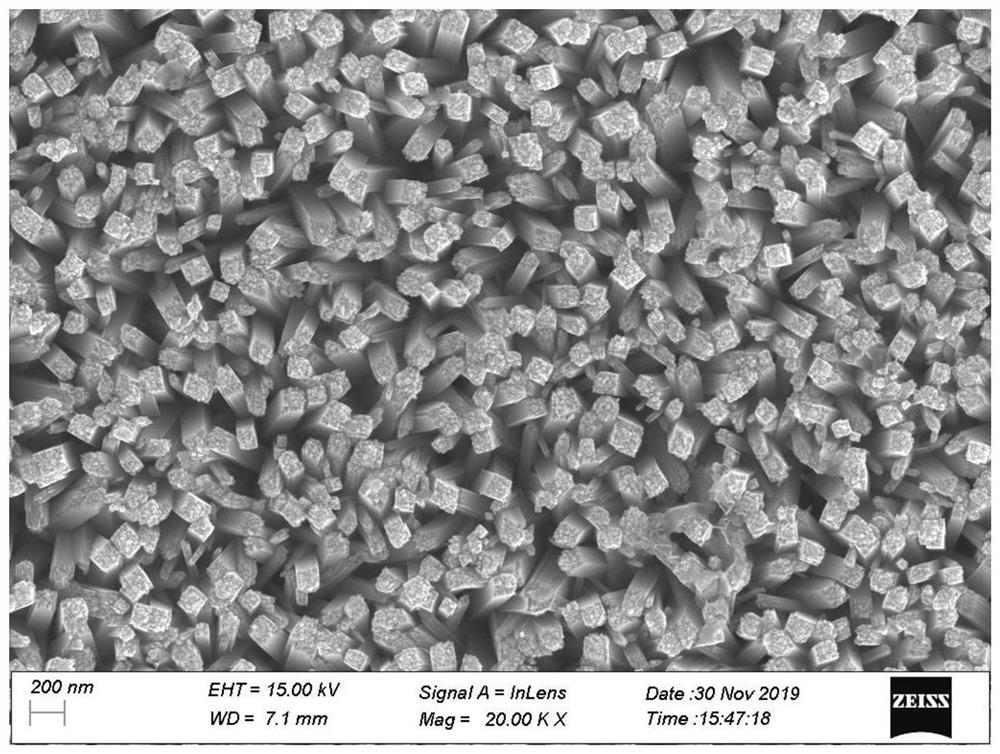

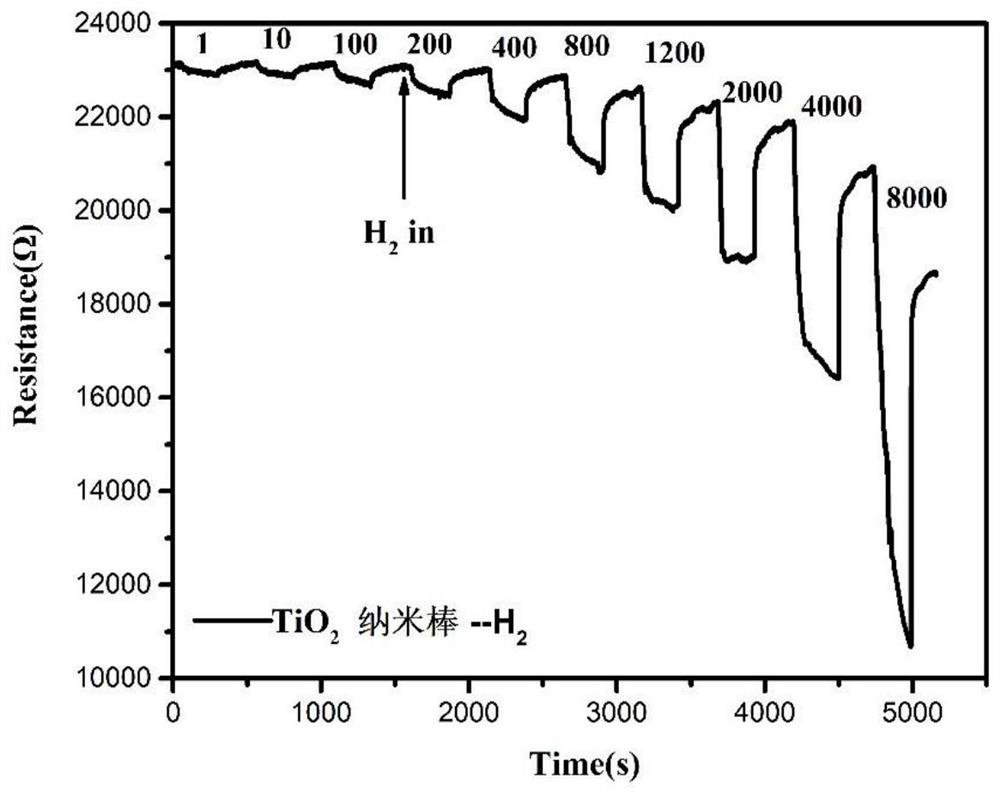

Embodiment 1

[0076] Put the FTO substrate against the inner wall of polytetrafluoroethylene in the hydrothermal reactor in a V shape, and pour the precursor prepared by 30mL deionized water, 0mL absolute ethanol, 30mL concentrated hydrochloric acid and 1mL tetrabutyl titanate solution, hydrothermal reaction at 150°C for 8h to obtain TiO 2 Nanorod film, after the reaction kettle is lowered to room temperature, wash the film with deionized water, soak it in deionized water, change the water every 3 hours, soak it for 6 hours, and dry it at a constant temperature at 70°C. Annealed at 400°C for 20min in air atmosphere and then ready for use.

[0077] The precursor solution (prepared from 0.59 g of nickel chloride hexahydrate, 100 mL of deionized water and 2 mL of ammonia water) was placed in a hydrothermal reactor, and two pieces of FTO (containing TiO 2 The nanorod film faces down) in a V shape and placed on the inner wall of the polytetrafluoroethylene reactor for hydrothermal reaction, and...

Embodiment 2

[0088] Put the FTO substrate against the inner wall of polytetrafluoroethylene in the hydrothermal reactor in a V shape, and pour the precursor prepared by 28mL deionized water, 2mL absolute ethanol, 30mL concentrated hydrochloric acid and 1mL tetrabutyl titanate. Bulk solution, hydrothermal reaction at 150°C for 8h to obtain TiO 2 Nanorod film, after the reaction kettle is lowered to room temperature, wash the film with deionized water, soak it in deionized water, change the water every 3 hours, soak it for 6 hours, and dry it at a constant temperature at 70°C. Annealed at 400°C for 20min in air atmosphere and then ready for use.

[0089] The precursor solution (prepared from 0.59 g of nickel chloride hexahydrate, 100 mL of deionized water, and 2 mL of ammonia water) was placed in a hydrothermal reactor, and two pieces of FTO (containing TiO 2 The nanorod film faces down) in a V shape and placed on the inner wall of the polytetrafluoroethylene reactor for hydrothermal reacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com