Silicon carbide crystal growth device and growth method thereof

A growth device, silicon carbide technology, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of inclusion defects, affecting the quality of silicon carbide crystals, etc., and achieve the effect of increasing sufficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

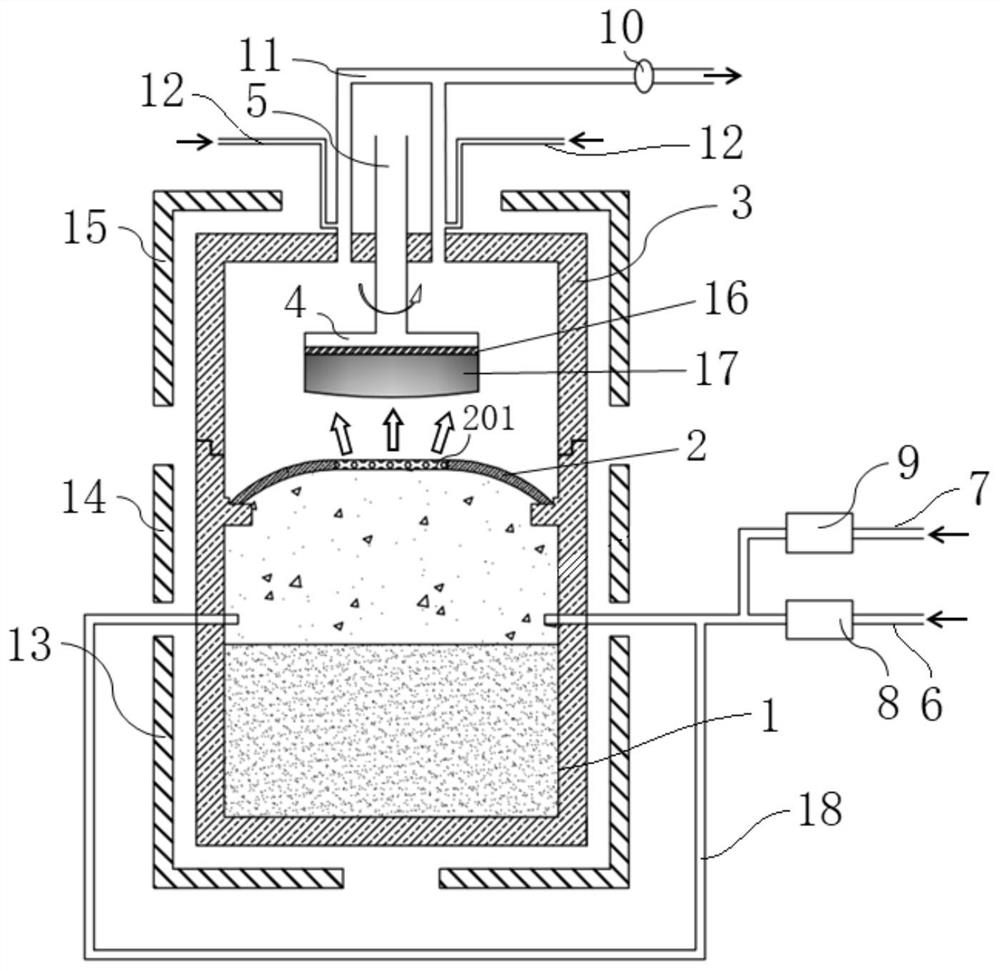

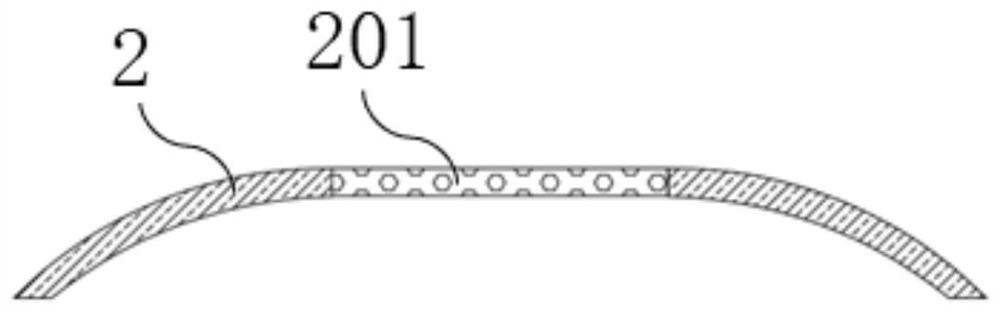

[0068] Such as figure 1 As shown, the high-purity silicon powder raw material is placed in the crucible body 1, and ethylene gas and argon gas enter from the first gas inlet pipe 6 and the second gas inlet pipe 7 through the first flow controller 8 and the second flow controller 9 respectively. into the gas reaction zone. The high-purity silicon powder raw material is heated by the first heater 13 to generate silicon vapor, and the silicon vapor reacts with the injected ethylene gas in the reaction zone to generate Si m C n Component gas phase. The temperature of the first heater 13 , the second heater 14 and the third heater 15 is adjusted so that the inner cavity of the crucible forms a temperature gradient required for gas sublimation from bottom to top. Si formed in the reaction zone m C n The gas phase of the components and the unreacted silicon vapor and ethylene gas are driven by the temperature gradient and sublime through the vent hole 201 in the middle region of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com