Multi-element gas co-infiltration strengthening system and process thereof

A technology of co-infiltration and gas, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problem of heat treatment of large and super large objects, poor corrosion resistance of treated parts, poor wear resistance, hardness, etc. Solve problems such as a single infiltration element to achieve the effect of improving environmental performance, reducing friction coefficient, and achieving uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with accompanying drawing and specific embodiment, the present invention is further described:

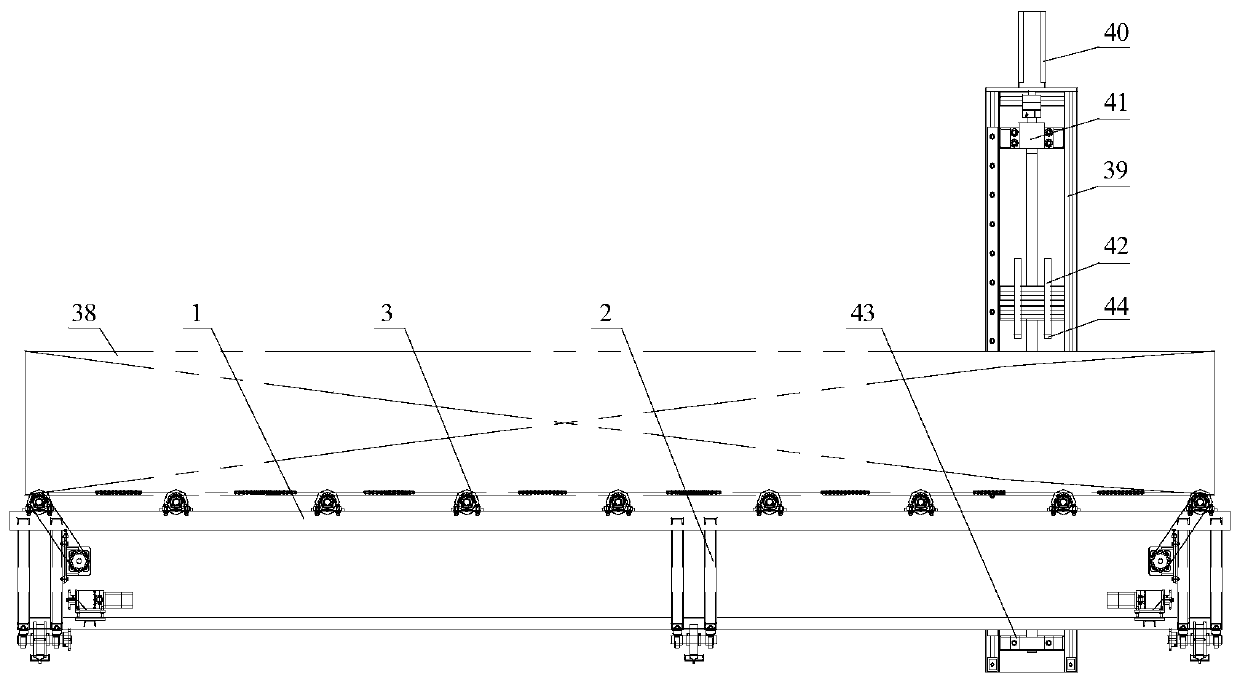

[0043] Such as figure 1 — Figure 8 As shown, a multi-component gas co-infiltration strengthening system includes a sequentially connected feeding unit, a ventilation unit, a heating pre-infiltration unit, a multi-component gas co-infiltration strengthening unit, a cooling protection unit, and a discharge unit;

[0044] The feeding unit includes a feeding vehicle frame 1, a feeding vehicle traveling mechanism 2 arranged below the feeding vehicle frame 1, and a plurality of conveying rollers 3 that run along the surface of the feeding vehicle frame 1 and run through each unit;

[0045] The ventilation unit includes a front ventilation chamber 4 placed at the front of the heating pre-infiltration unit and a rear ventilation chamber 5 placed at the rear of the cooling protection unit;

[0046] The heating pre-infiltration unit includes a heating furnace, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com