Method for preparing CuCr-MgBi contact material through electromagnetic-ultrasonic suspension smelting

A technology of suspending smelting and contact materials, applied in contact materials, contacts, circuits, etc., to achieve the effects of strong breaking capacity, reduced segregation, and increased crystal defect density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

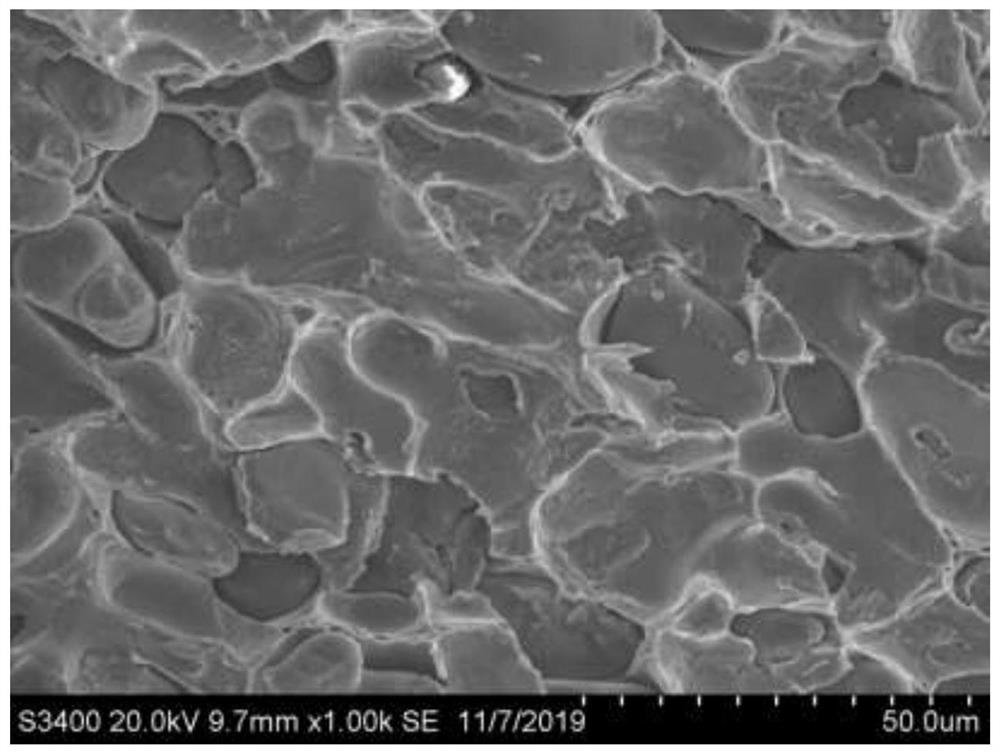

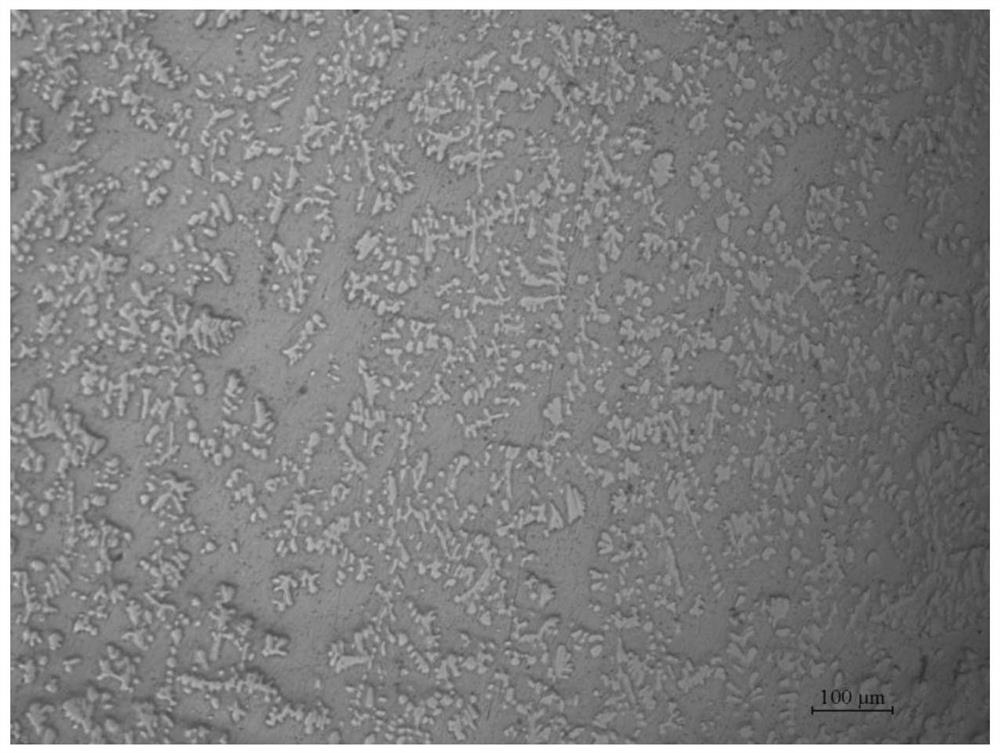

Examples

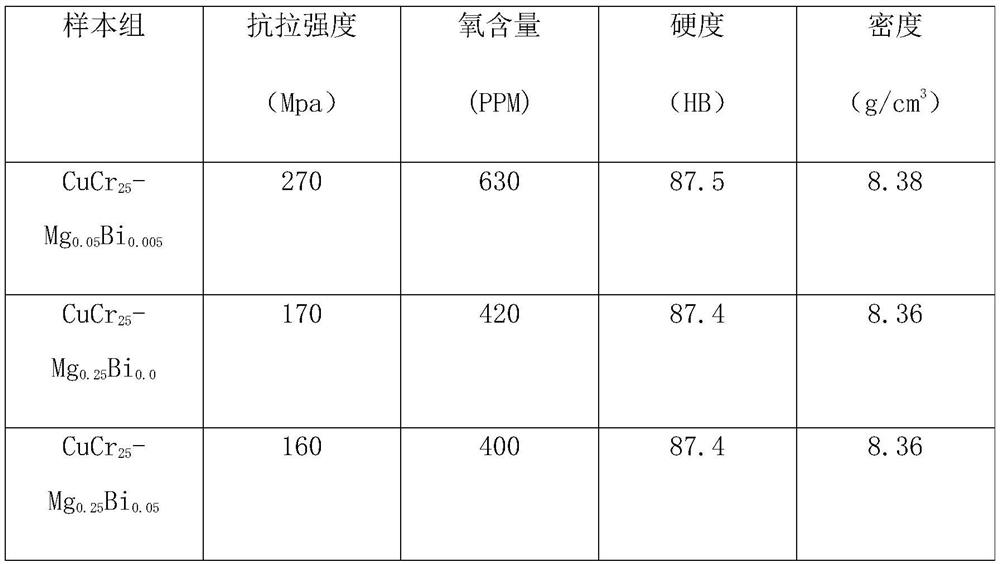

Embodiment 1

[0045] 1. Ingredients: Weigh Cr ingots, Cu ingots, CuMg alloy ingots, and Bi ingots as alloy samples, in which the Cr content is 25%, the Mg content is 0.05%, and the Bi content is 0.005%.

[0046] 2. Furnace loading: Put the Cr block, Cu block, and CuMg alloy block on the hollow ceramic support rod of the closed container system, and put the Bi block into the secondary feeding device.

[0047] 3. Ultrasonic levitation: vacuumize the airtight container system to 10 -1 Pa; Turn on the ultrasonic standing wave generator to make the sample suspended stably.

[0048] 4. Induction heating: Turn on the high-frequency induction heater, and heat according to the temperature gradient of 10KW, 20KW, 30KW, 40KW and the stirring frequency of 150KHz.

[0049] (1) The 10KW stage is maintained for 1min, and the distance between the radiation end and the reflection end is adjusted to increase the suspension force compensation.

[0050] (2) The 20KW and 30KW phases are maintained for 1 minut...

Embodiment 2

[0059] 1. Ingredients: Weigh Cr ingots, Cu ingots, CuMg alloy ingots, and Bi ingots as alloy samples, in which the Cr content is 30%, the Mg content is 0.25%, and the Bi content is 0.05%.

[0060] 2. Furnace loading: Put the Cr block, Cu block, and CuMg alloy block on the hollow ceramic support rod of the closed container system, and put the Bi block into the secondary feeding device.

[0061] 3. Ultrasonic levitation: vacuumize the airtight container system to 10 -1 Pa; Turn on the ultrasonic standing wave generator to make the sample suspended stably.

[0062] 4. Induction heating: Turn on the high-frequency induction heater, and heat according to the temperature gradient of 10KW, 20KW, 30KW, 40KW and the stirring frequency of 150KHz.

[0063] (1) The 10KW stage is maintained for 2 minutes, and the distance between the radiation end and the reflection end is adjusted to increase the suspension force compensation.

[0064] (2) The 20KW and 30KW phases are maintained for 2 m...

Embodiment 3

[0073] 1. Ingredients: Weigh Cr lumps, Cu lumps, CuMg alloy lumps, and Bi lumps as alloy samples, in which the Cr content is 30%, the Mg content is 0.25%, and the Bi content is 0.05%.

[0074] 2. Furnace loading: Put the Cr block, Cu block, and CuMg alloy block on the hollow ceramic support rod of the closed container system, and put the Bi block into the secondary feeding device.

[0075] 3. Ultrasonic levitation: vacuumize the airtight container system to 10 -1 Pa; Turn on the ultrasonic standing wave generator to make the sample suspended stably.

[0076] 4. Induction heating: Turn on the high-frequency induction heater, and heat according to the temperature gradient of 10KW, 20KW, 30KW, 40KW and the stirring frequency of 150KHz.

[0077] (1) The 10KW stage is maintained for 3 minutes, and the distance between the radiation end and the reflection end is adjusted to increase the suspension force compensation.

[0078] (2) The 20KW and 30KW phases are maintained for 3 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com