PC/ABS alloy material for household appliances

A technology for alloy materials and home appliances, which is applied in the field of alloy plastics, can solve problems such as single material does not show shielding performance, polymer material preparation is complicated, and the aging resistance of alloy materials is reduced, so as to reduce electromagnetic pollution, good electromagnetic shielding performance, Good absorption coefficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

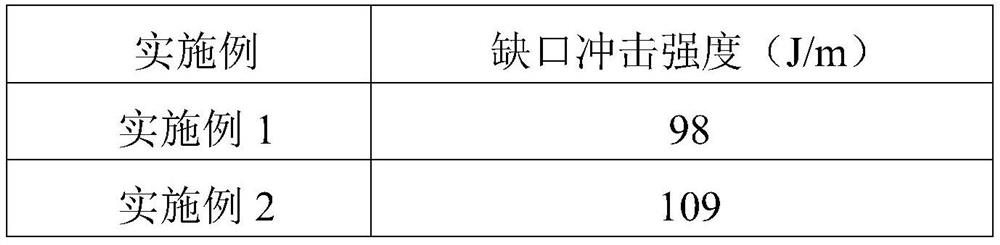

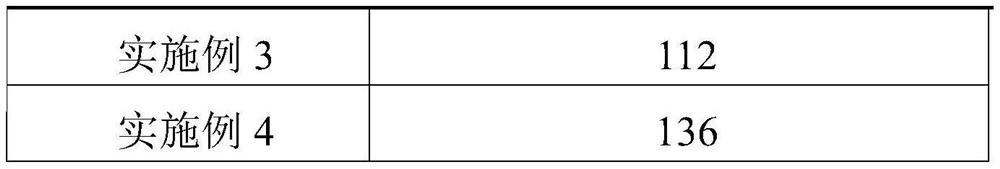

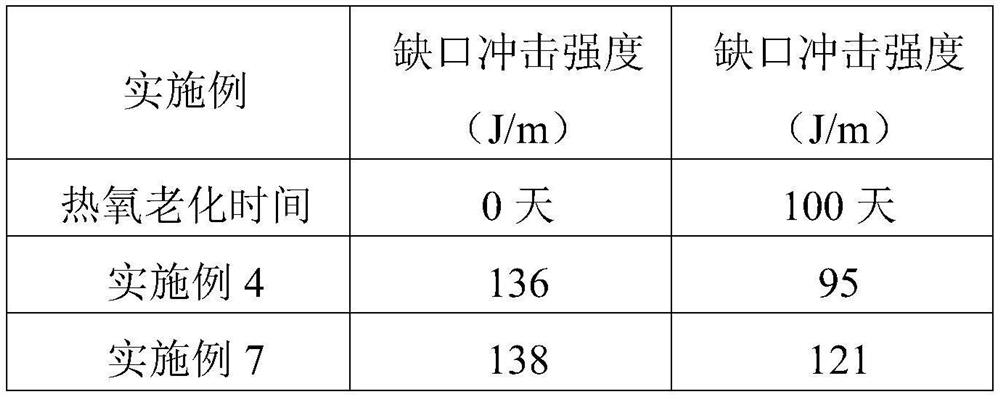

Examples

Embodiment 1

[0053] A PC / ABS alloy material for household appliances, consisting of the following raw materials in parts by weight: 58.3 parts of PC resin, 25 parts of ABS resin, 8 parts of straw biochar material, 8 parts of compatible toughening agent, 0.3 part of antioxidant, lubricating 0.4 parts of the agent. Dry PC resin at 125°C for 3.5 hours, dry ABS resin at 80°C for 4 hours, mix 58.3 parts of PC resin, 25 parts of ABS resin, 8 parts of modified straw biochar materials, 8 parts of compatible toughening agent, 0.3 parts of oxygen agent and 0.4 parts of lubricant were mixed, extruded and granulated in a twin-screw extruder at 240° C., and dried at 100° C. for 8 hours to obtain the PC / ABS alloy material for household appliances.

[0054] The compatible toughening agent is methyl methacrylate-butadiene-styrene terpolymer toughening agent, brand: EXL-2620, Dow Chemical.

[0055] The antioxidant is Antioxidant 1010, full name tetrakis(3,5-di-tert-butyl-4-hydroxyhydrocinnamic acid) penta...

Embodiment 2

[0059] A PC / ABS alloy material for household appliances, consisting of the following raw materials in parts by weight: 58.3 parts of PC resin, 25 parts of ABS resin, 8 parts of modified straw biochar material, 8 parts of compatible toughening agent, and 0.3 part of antioxidant , 0.4 part of lubricant. Dry PC resin at 125°C for 3.5 hours, dry ABS resin at 80°C for 4 hours, mix 58.3 parts of PC resin, 25 parts of ABS resin, 8 parts of modified straw biochar materials, 8 parts of compatible toughening agent, 0.3 parts of oxygen agent and 0.4 parts of lubricant were mixed, extruded and granulated in a twin-screw extruder at 240° C., and dried at 100° C. for 8 hours to obtain the PC / ABS alloy material for household appliances.

[0060] The compatible toughening agent is methyl methacrylate-butadiene-styrene terpolymer toughening agent, brand name: EXL-2620, Dow Chemical.

[0061] The antioxidant is Antioxidant 1010, full name tetrakis(3,5-di-tert-butyl-4-hydroxyhydrocinnamic acid) p...

Embodiment 3

[0067] A PC / ABS alloy material for household appliances, consisting of the following raw materials in parts by weight: 58.3 parts of PC resin, 25 parts of ABS resin, 8 parts of modified straw biochar material, 8 parts of compatible toughening agent, and 0.3 part of antioxidant , 0.4 part of lubricant. Dry PC resin at 125°C for 3.5 hours, dry ABS resin at 80°C for 4 hours, mix 58.3 parts of PC resin, 25 parts of ABS resin, 8 parts of modified straw biochar materials, 8 parts of compatible toughening agent, 0.3 parts of oxygen agent and 0.4 parts of lubricant were mixed, extruded and granulated in a twin-screw extruder at 240° C., and dried at 100° C. for 8 hours to obtain the PC / ABS alloy material for household appliances.

[0068] The compatible toughening agent is methyl methacrylate-butadiene-styrene terpolymer toughening agent, brand name: EXL-2620, Dow Chemical.

[0069] The antioxidant is Antioxidant 1010, full name tetrakis(3,5-di-tert-butyl-4-hydroxyhydrocinnamic acid)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com