A kind of preparation method and application of dithiocarbamate iron complex catalyst

A technology of dithiocarbamate and dimethyldithiocarbamate is applied in the field of preparation of iron dithiocarbamate complex catalysts, which can solve problems such as poor recycling performance and achieve low pollution and high catalytic activity. , the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

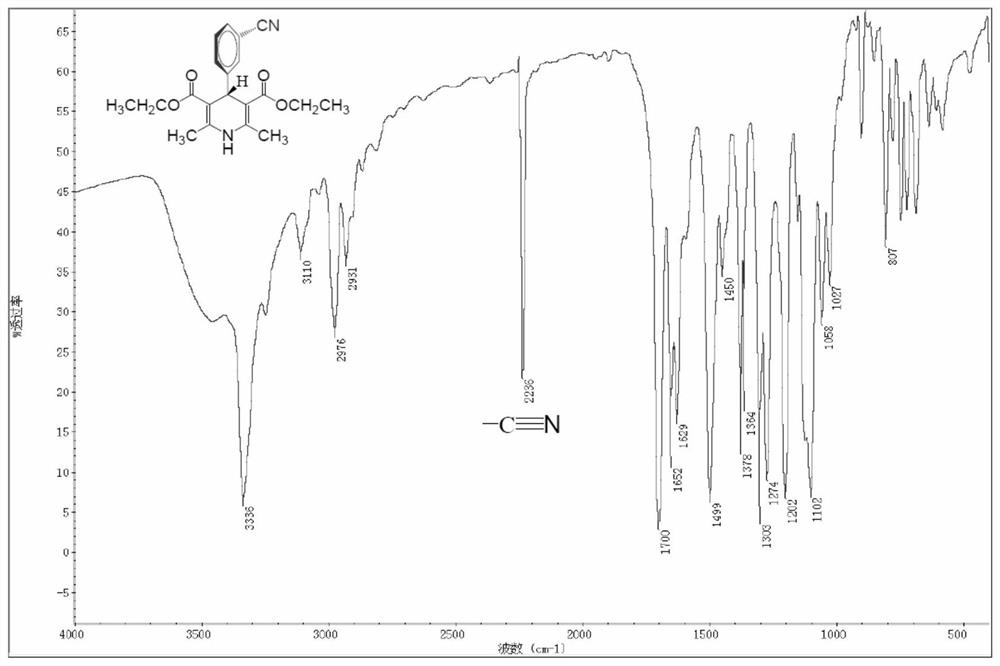

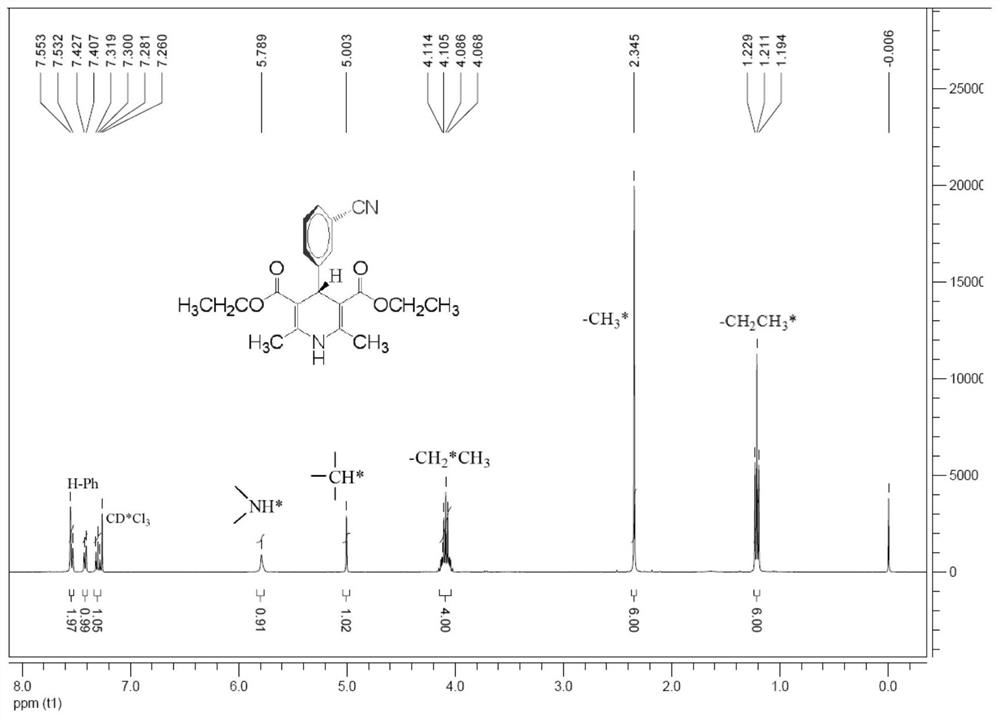

[0019] Take by weighing 1.0mmol, the ferrous ammonium sulfate (NH 4 ) 2 Fe(SO 4 ) 2 ·6H 2 O and 3.0mmol, 0.363g of N,N-dimethyldithiocarbamate, placed in a round bottom flask, add 10mL of distilled water, 5.0mL of ethanol and 1.0mL of DMF, stir at room temperature for 10min, adjust the pH of the solution with ammonia water The value is 5, and the mixture solution is obtained. The mixture solution is transferred to a stainless steel reactor at 130 ° C for 72 hours, naturally cooled to room temperature, and separated by filtration to obtain a reddish-brown block crystal, which is an iron dithiocarbamate complex. Yield 93%. The prepared iron complex was used as the catalyst for the Hantzsch reaction, and the reaction raw materials of ethyl acetoacetate, 3-cyanobenzaldehyde and ammonium acetate were carried out in a mixed solvent with a volume ratio of ethanol and water of 1:1, and the catalytic reaction experiment was carried out And catalyst recycling experiment test.

Embodiment 2

[0021] Take by weighing 1.0mmol, the ferrous ammonium sulfate (NH 4 ) 2 Fe(SO 4 ) 2 ·6H 2 O and 3.0mmol, 0.363g of N,N-dimethyldithiocarbamate, placed in a round bottom flask, add 10mL of distilled water, 5.0mL of ethanol and 1.0mL of DMF, stir at room temperature for 10min, adjust the pH of the solution with ammonia water The value is 6, and the mixture solution is obtained. The mixture solution is transferred to a stainless steel reactor at 160 ° C for 24 hours, naturally cooled to room temperature, and separated by filtration to obtain a reddish-brown block crystal, which is an iron dithiocarbamate complex. Yield 90.5%. The prepared iron complex was used as the catalyst for the Hantzsch reaction, and the reaction raw materials of ethyl acetoacetate, 3-cyanobenzaldehyde and ammonium acetate were carried out in a mixed solvent with a volume ratio of ethanol and water of 1:1, and the catalytic reaction experiment was carried out And catalyst recycling experiment test.

Embodiment 3

[0023] Take by weighing 1.0mmol, the ferrous ammonium sulfate (NH 4 ) 2 Fe(SO 4 ) 2 ·6H 2 O and 3.0mmol, 0.363g of N,N-dimethyldithiocarbamate, placed in a round bottom flask, add 10mL of distilled water, 5.0mL of ethanol and 1.0mL of DMF, stir at room temperature for 10min, adjust the pH of the solution with ammonia water The value was 5.5, and the mixture solution was obtained. The mixture solution was transferred to a stainless steel reactor at 140 ° C for 48 hours, cooled to room temperature naturally, filtered and separated to obtain a reddish-brown block crystal, which was an iron dithiocarbamate complex. Yield 92%.

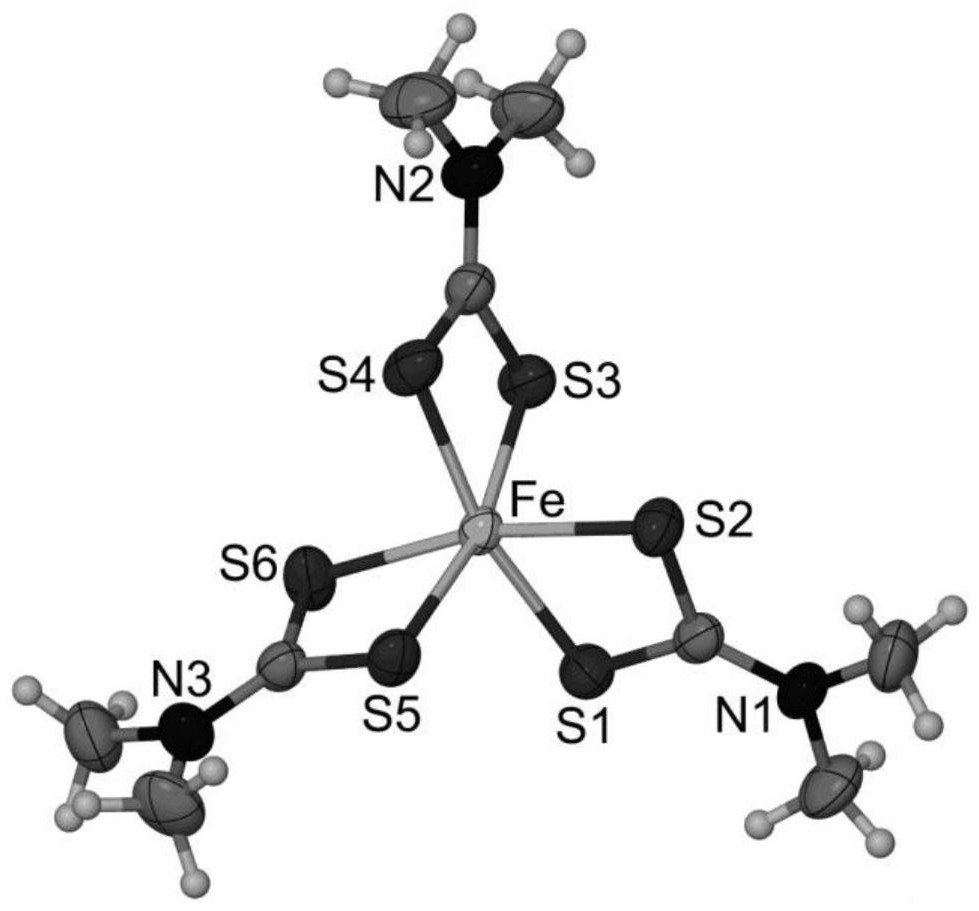

[0024] Select the reddish-brown block crystal that makes in the above-mentioned embodiment that size is suitable to carry out X-ray single-crystal diffraction test analysis, after determination asymmetric structure unit is by an Fe (III) ion and three dithiocarbamate radicals (L - ) composition, its structural formula is [Fe(L) 3 ], the crystal system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com