A kind of normal temperature NTC thermistor thin film and preparation method thereof

A technology of thermistor and thin film, which is applied in the field of normal temperature NTC thermistor thin film and its preparation, can solve the problems of affecting the performance of the thin film, reducing the TCR value, and cannot be directly applied to the field of infrared measurement, etc., and achieves a good crystallization state and a simple thin film Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

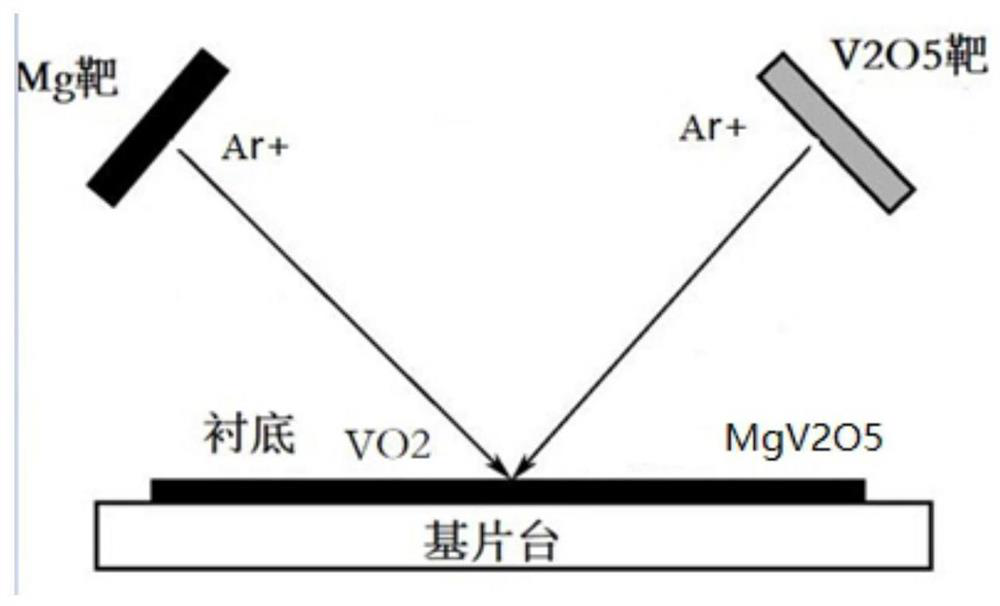

[0039] In this embodiment, an ordinary P-type (100) silicon wafer is used as a substrate, and an NTC film is prepared on its surface, such as figure 1 shown; the specific steps are as follows.

[0040] 1. Clean the substrate: soak the silicon wafer in dilute hydrochloric acid (10% HCL) for 5 minutes to remove metal ions. After rinsing, soak in acetone and isopropanol for 5 minutes to remove oil stains, then rinse and dry in a nitrogen oven.

[0041] 2. Equipment and target selection: The sputtering equipment is denton multi-target magnetron sputtering coating machine, the target is 3 inches in diameter, 5 mm thick, metal magnesium with a purity of 99.999% and vanadium pentoxide ceramic target with a purity of 99.999% .

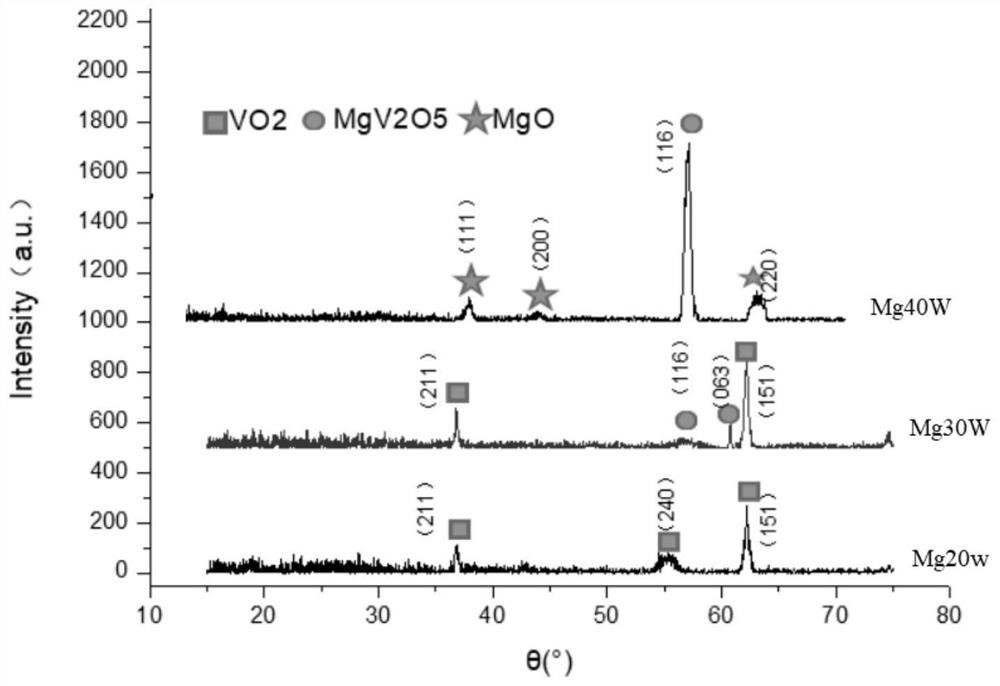

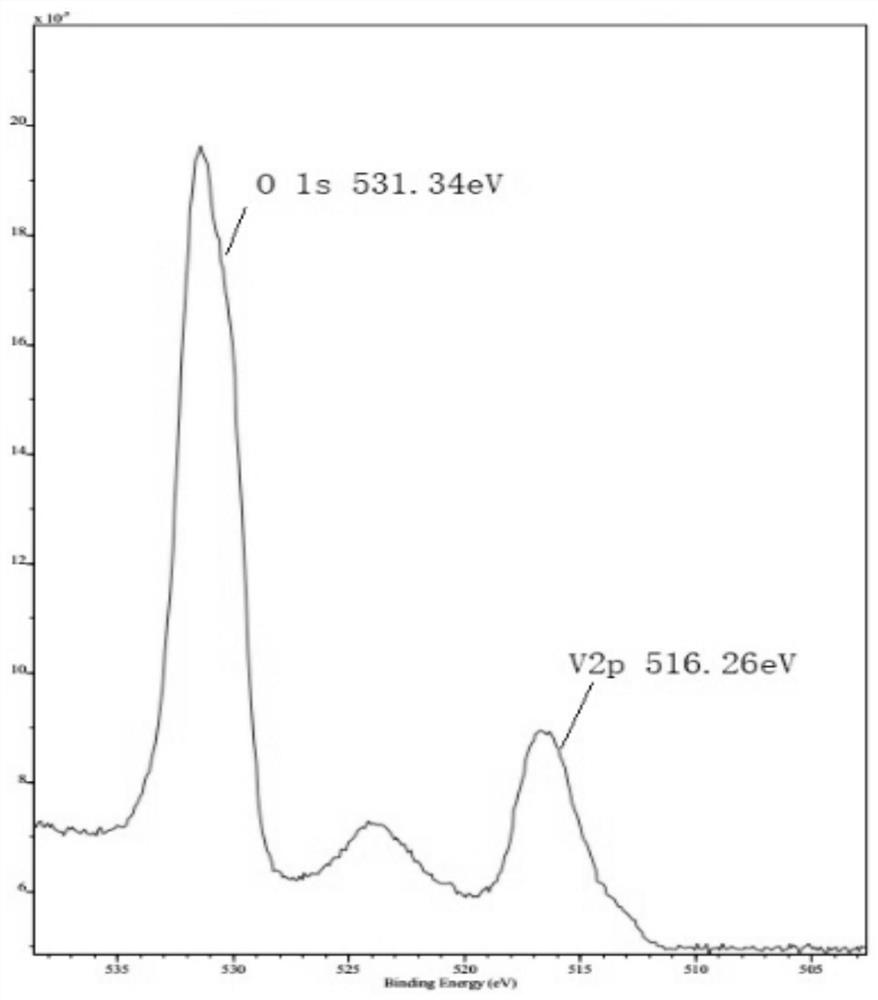

[0042] 3. Thin film deposition: put the substrate on the water-cooled workpiece table, close the chamber, and pump the vacuum to 3*10 -4 After Pa, set the argon gas flow rate to 30 sccm, the working pressure to 0.6 pa, the magnesium target power to 100 W, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com