Corrosion-resistant high-strength pearlite steel rail and preparation method thereof

A pearlite rail, high-strength technology, applied in the field of metallurgy, can solve problems that do not involve the corrosion resistance of rails, and achieve the effect of improving service performance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

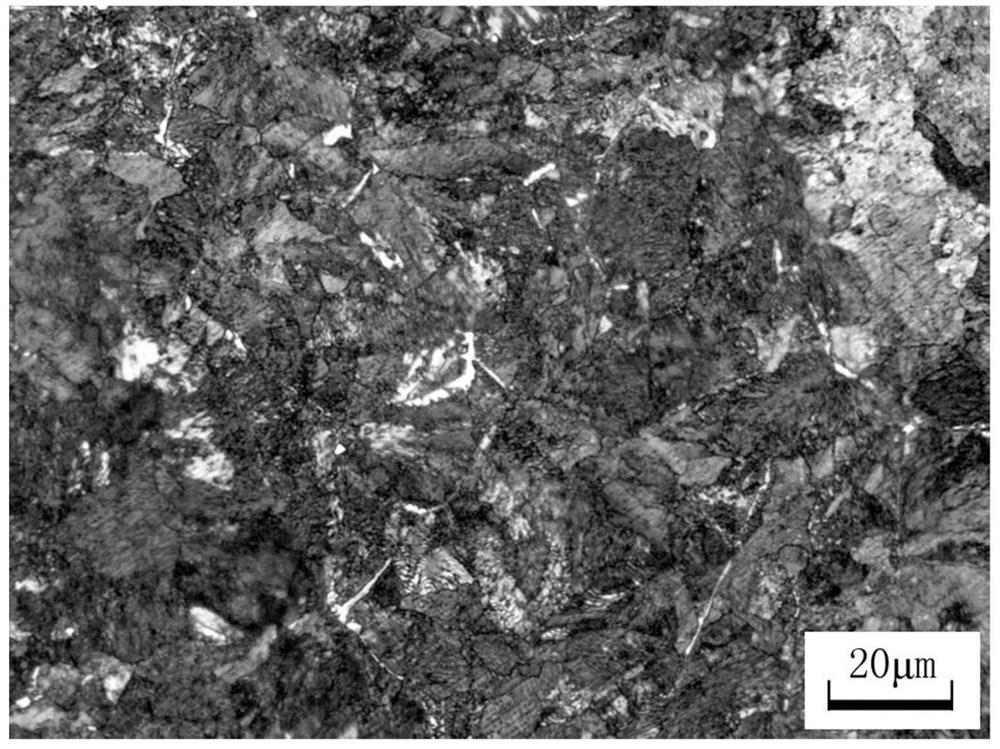

Image

Examples

Embodiment 1

[0085] Example 1: Hot metal desulfurization adopts magnesium powder desulfurization process, converter smelting adopts top-bottom combined blowing process, and controls the tapping temperature at 1670°C; the slag alkalinity of LF refining outside the furnace is controlled at 1.7, and the vacuum treatment time is 28 minutes; RH adopts Deep vacuum treatment, the treatment time of pressure ≤ 50Pa is 17min; the continuous casting process adopts the long nozzle of the large tank and the submerged nozzle of the crystallizer to protect the pouring, prevent contact with air, the immersion depth is 70mm, and the temperature of the tundish is controlled at 16℃ above the liquidus line , the billet casting speed is controlled at 0.4m / min, and the cast billet should be slowly cooled, the cooling rate is controlled at 0.1°C / s, and water spraying on the billet surface is strictly prohibited; the billet is heated by a walking beam heating furnace, and Carry out heat preservation treatment, the...

Embodiment 2

[0086] Example 2: Hot metal desulfurization adopts magnesium powder desulfurization process, converter smelting adopts top-bottom combined blowing process, and controls the tapping temperature at 1680°C; the slag alkalinity of LF refined outside the furnace is controlled at 1.8, and the vacuum treatment time is 30 minutes; RH adopts Deep vacuum treatment, the treatment time is 20 minutes when the pressure is less than or equal to 50Pa; the continuous casting process adopts the long nozzle of the large tank and the submerged nozzle of the crystallizer to protect the pouring, prevent contact with air, the immersion depth is 75mm, and the temperature of the tundish is controlled at 20°C above the liquidus line , the billet casting speed is controlled at 0.5m / min, and the cast billet should be slowly cooled, the cooling rate is controlled at 0.3°C / s, and it is strictly forbidden to spray water on the billet surface; the billet is heated by a walking beam heating furnace, and Carry ...

Embodiment 3

[0087] Example 3: Hot metal desulfurization adopts magnesium powder desulfurization process, converter smelting adopts top-bottom combined blowing process, and controls the tapping temperature at 1685°C; the slag alkalinity of LF refined outside the furnace is controlled at 2.1, and the vacuum treatment time is 32 minutes; RH adopts Deep vacuum treatment, the treatment time of pressure ≤ 50Pa is 18min; the continuous casting process adopts the long nozzle of the large tank and the immersed nozzle of the crystallizer to protect the pouring, prevent contact with air, the immersion depth is 72mm, and the temperature of the tundish is controlled at 18℃ above the liquidus line , the billet casting speed is controlled at 0.6m / min, and the cast billet should be slowly cooled at a rate of 0.2°C / s, and it is strictly forbidden to spray water on the billet surface; Carry out heat preservation treatment, the heating temperature is 1230°C, the heat preservation time is 200min, the rolling ...

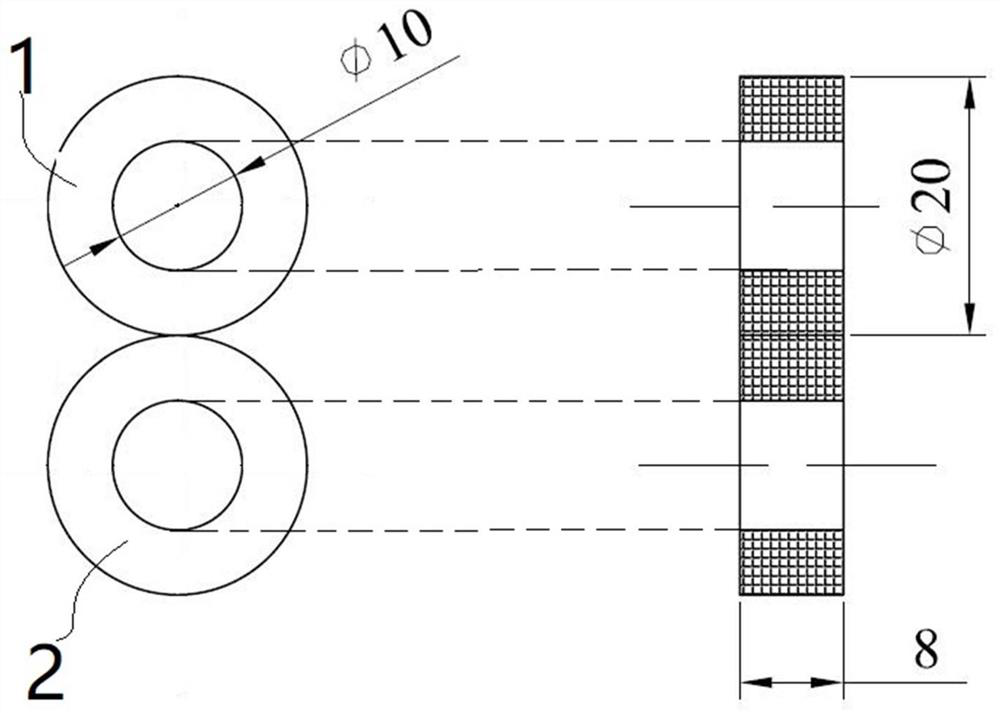

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com