A kind of fecral stainless steel composite pipe blank and preparation method thereof

A technology of stainless steel and composite pipe, applied in the field of FeCrAl stainless steel composite pipe blank and its preparation, can solve the problems of unsatisfactory and prone to interlayer peeling, and achieve the effects of reducing porosity, uniform microstructure and reasonable particle size composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

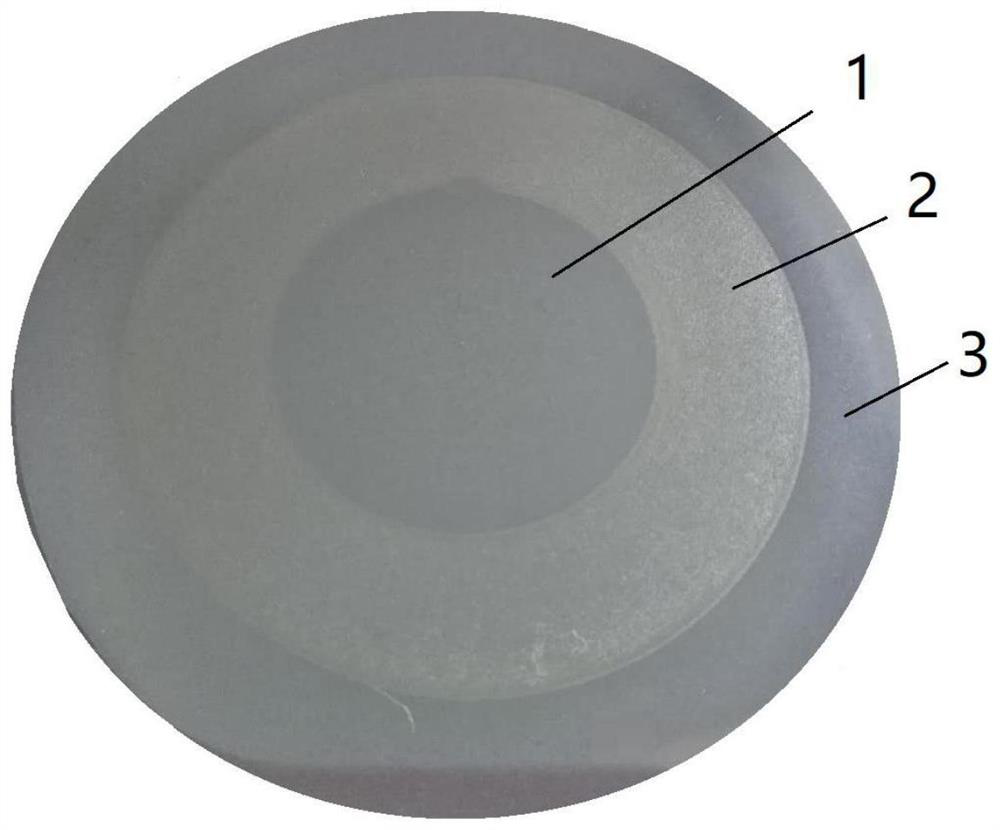

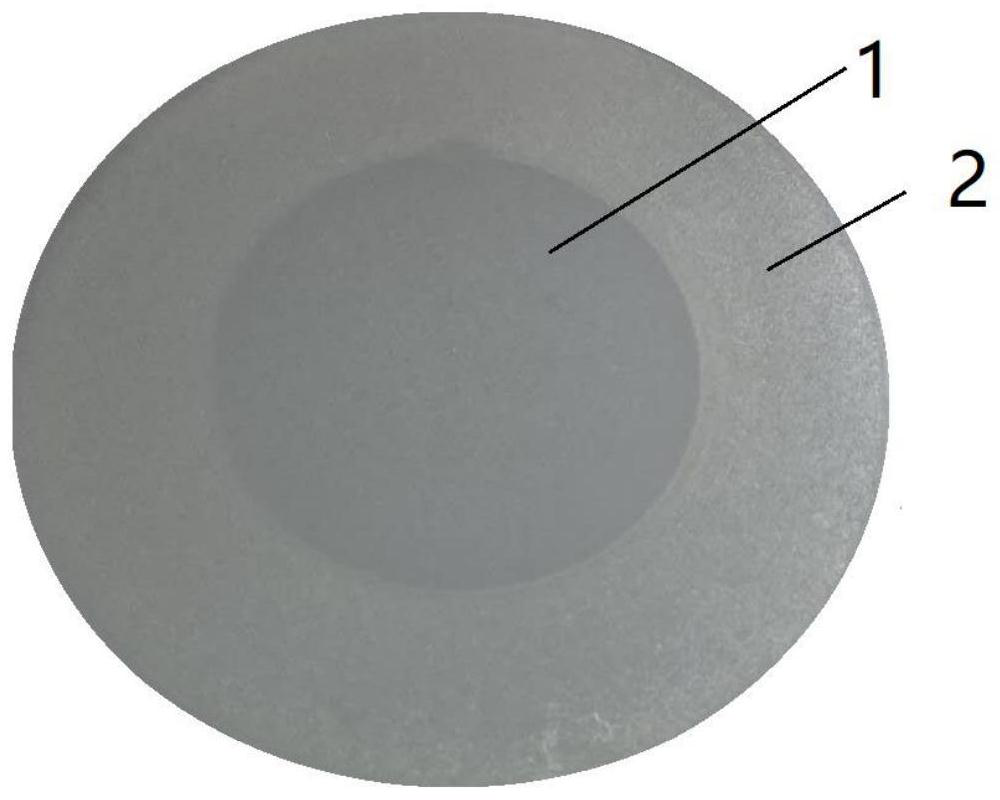

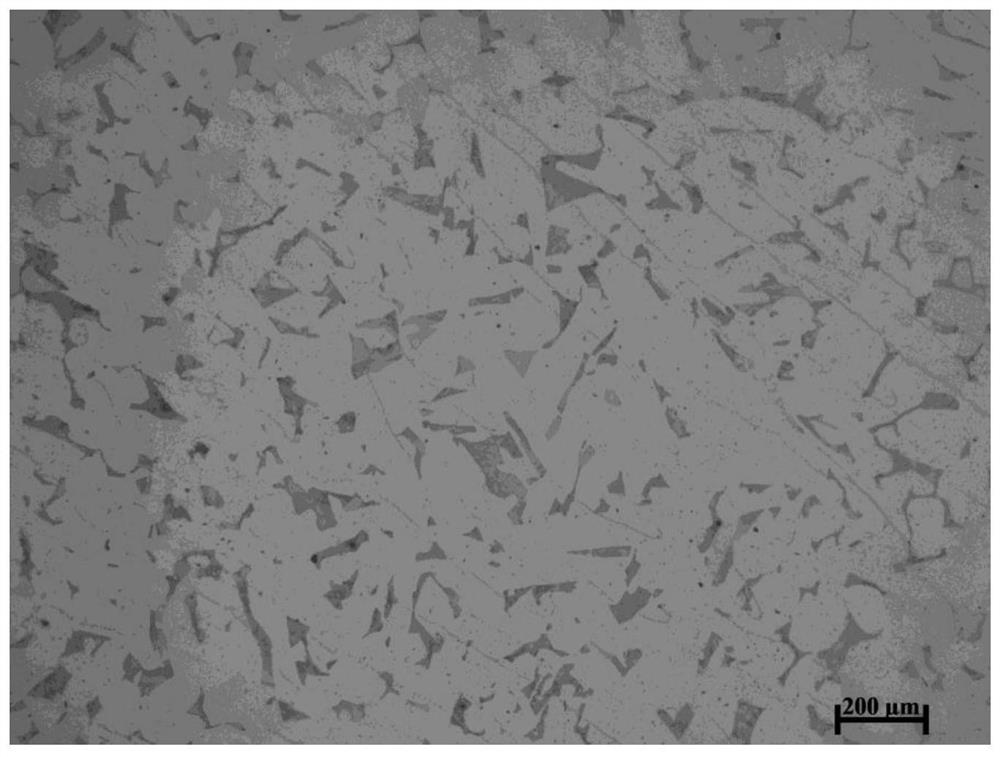

[0040] The preparation principle adopted in the present invention is: the present invention prepares the FeCrAl stainless steel layer 2 by powder metallurgy on a mandrel made of metal such as stainless steel or alloy steel, so that the T91 steel mandrel layer 1 and the FeCrAl stainless steel layer 2 are formed. The metallurgical bonding layer 4 satisfies comprehensive requirements such as mechanical properties and corrosion resistance. Specifically, FeCrAl stainless steel ingots (i.e. FeCrAl stainless steel bar master material) are smelted by vacuum induction process, and high-quality FeCrAl stainless steel powder with low O content (oxygen content is lower than 0.0014wt%) is prepared by plasma rotating electrode atomization. After the powder is sieved To obtain stainless steel powder with small particle size and uniform size, powder metallurgy is carried out on the sheathing device containing T91 steel mandrel and FeCrAl stainless steel powder by hot isostatic pressing to obta...

Embodiment 1

[0052] This embodiment provides a method for preparing a FeCrAl stainless steel composite tube blank, comprising the following steps:

[0053] Step 1. Use a 25kg vacuum induction furnace to smelt steel ingots after iron washing in the forehearth, and use pure iron, Ni plate, J-Cr, and aluminum blocks to smelt Benxi Steel. The chemical composition of the cast FeCrAl stainless steel ingot is shown in Table 1.

[0054] FeCrAl stainless steel ingots are subjected to vacuum degreasing treatment: the vacuum degree is 0.13Pa, the temperature is 320°C, and the temperature is kept for 5h after reaching the temperature. Steel ingots are cooled to 80°C in a vacuum chamber and released.

[0055] Step 2. Prepare FeCrAl stainless steel powder by plasma rotating electrode atomization, the vacuum degree is 0.2Pa, the air leakage rate is 0.8Pa / min; the ingot speed is 15000r / min, the plasma arc current is 2000A, and the plasma working gas flow rate is 280L / min ; The FeCrAl stainless steel pow...

Embodiment 2

[0061] This embodiment provides a method for preparing a FeCrAl stainless steel composite tube blank, comprising the following steps:

[0062] Step 1. Use a 25kg vacuum induction furnace to smelt steel ingots after iron washing in the forehearth, and use pure iron, Ni plate, J-Cr, and aluminum blocks to smelt Benxi Steel. The chemical composition of the cast FeCrAl stainless steel ingot is shown in Table 1.

[0063] The FeCrAl stainless steel ingot is subjected to vacuum degreasing treatment: the vacuum degree is 0.13Pa, the temperature is 500°C, and after reaching the temperature, it is kept for 0.5h, and the steel ingot is cooled to 100°C in the vacuum chamber and released from the furnace.

[0064] Step 2. Prepare FeCrAl stainless steel powder by plasma rotating electrode atomization method, the vacuum degree is 0.13Pa, the air leakage rate is 1.0Pa / min; the ingot speed is 11000r / min, the plasma arc current is 1300A, and the plasma working gas flow rate is 35L / min ; FeCrAl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com