Back protection film of solar cell

A technology for back protection film and solar cells, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of interlayer detachment, and achieve the effect of improving adhesion, good hydrolysis resistance, and not easy interlayer detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] An adhesive, which is a copolyester resin prepared by the following process: put terephthalic acid, isophthalic acid, adipic acid, 2 , 2-dimethylpropanediol, ethylene glycol, and antimony trioxide as a polymerization catalyst containing 0.04 mol% of all acid components, and carried out esterification reaction for 4 hours while raising the temperature from 160°C to 240°C. Subsequently, the pressure in the boiler was gradually reduced to 650 Pa after 1 hour. The pressure was reduced to 40 Pa while raising the temperature to 265° C., and a polymerization reaction was implemented for 3 hours while maintaining 265° C. and 40 Pa or less. The properties of the copolyester resin thus obtained are shown in Table 1.

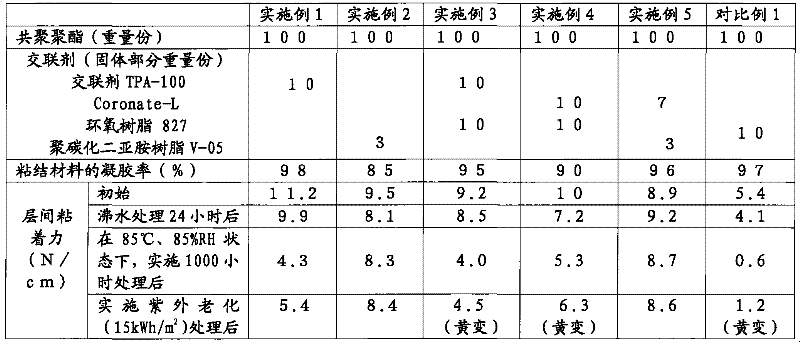

Embodiment 2~5 and comparative example 1

[0040] The copolyester resins provided in Examples 2-5 and Comparative Example 1 were prepared by the same method as Example 1, except that the raw materials and usage amounts of the esterification reaction were different. See Table 1 for details.

[0041] Table 1

[0042] Example 1 Example 2 Example 3 Example 4 Example 5 Comparative example 1 Acid Composition TPA IPA AA SA DA TMA 30 30 40 42 58 37 18 45 50 25 25 41 57 2 20 20 60 Diol composition 2-MPD 2,2-DMPD 1,5-PD 1,6-HD EG DEG 45 55 20 80 31 69 25 75 11 89 50 50 intrinsic viscosity 0.57 0.50 0.54 0.53 0.55 0.59 Specific gravity (g 1.23 1.22 1.19 1.18 1.21 1.15

[0043] In Table 1, TPA: terephthalic acid; IPA: isophthalic acid; AA: adipic acid; SA: sebacic acid; DA: 1,10-methenyl dicarboxylic acid; TMA: trimellitic anhydride; MPD: 2-methyl-1,3-propanediol...

Embodiment 6

[0045] This embodiment provides a method for making a solar cell protective film, which is as follows: 18g of copolyester resin is dissolved in 27g of ethyl acetate, and then 1.8g of crosslinking agent TPA-100 (a trifunctional product manufactured by Asahi Kasei Chemical Co., Ltd.) is added. isocyanate compounds). A commercially available 250 μm polyethylene terephthalate film (Oriental #6021) and 30 μm polyvinylidene fluoride film (Arkema #302) with corona treatment on both sides is usually required. First, the prepared solution of the above-mentioned copolyester resin was applied to one side of a polyethylene terephthalate film, and then dried at 90° C. for 10 minutes. The thickness of the coating layer after drying was 17 μm. Next, compound the coated side of the solution to the above-mentioned polyvinylidene fluoride film, at 80°C, 2.5kg / cm 2 After heating and pressing for 3 minutes in the state of , heating at 80° C. for 3 hours and performing a crosslinking reaction. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com