An industrial waste gas treatment device and treatment method thereof

A technology for industrial waste gas and waste gas, which is applied in separation methods, gas treatment, chemical instruments and methods, etc., can solve the problems of affecting waste gas treatment efficiency, easily blocked filter parts, and reduced filtering effect, so as to improve adsorption efficiency and ensure adsorption. The effect of improving the adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

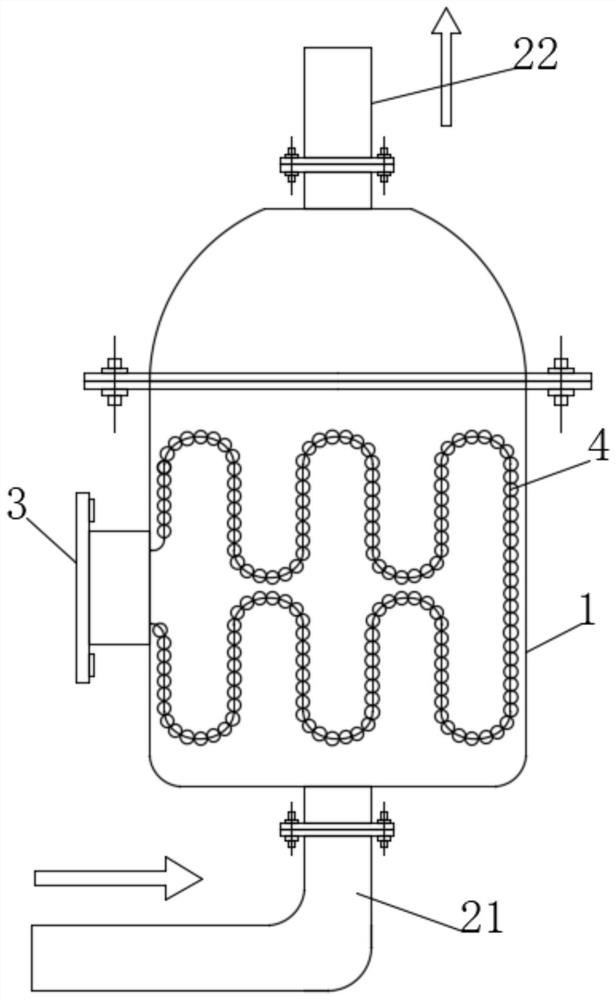

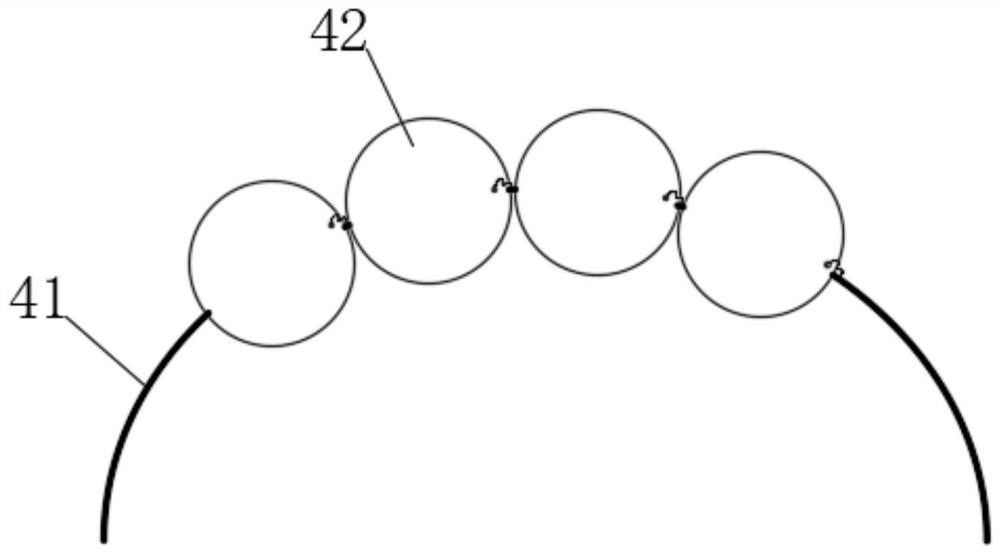

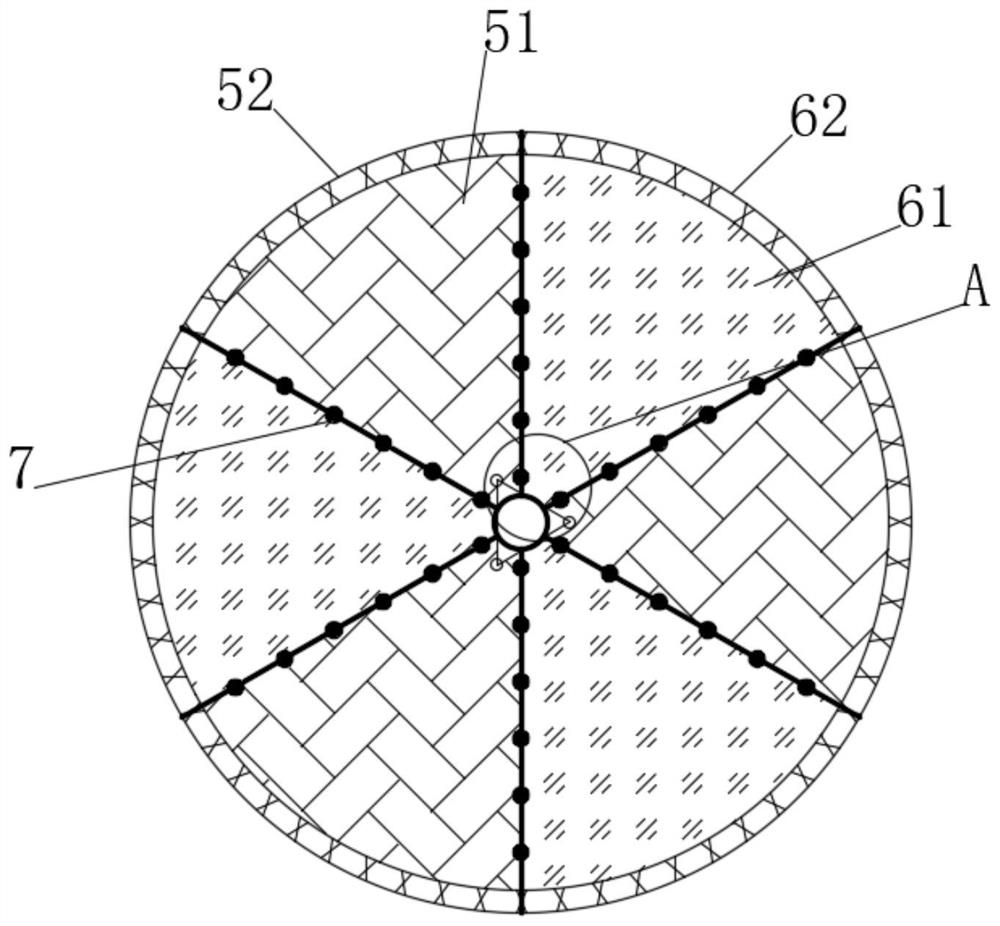

[0046] see Figure 1-2 , an industrial waste gas treatment device, comprising a device body 1, the upper and lower ends of the device body 1 are respectively fixedly connected with an air inlet pipe 21 and an air outlet pipe 22, both the air inlet pipe 21 and the air outlet pipe 22 communicate with the inside of the device body 1, and the inside of the device body 1 There are a plurality of self-falling-off adsorption plates 4 that are in contact with each other in a fixed connection. The loop-back self-falling adsorption plates 4 include special-shaped rods 41 and a plurality of semi-shedding adsorption balls 42 that are slidably connected on the special-shaped rods 41. Two adjacent half-shedding adsorption balls 42 are in contact with each other, and the left end of the device body 1 is fixedly connected with a filling channel 3 with a valve. The special-shaped rod 41 is a circular reciprocating structure with up and down symmetry, and the two ends of the special-shaped rod 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com