Deoxidizing technology for electric furnace steel ladle

A technology of electric furnace steel and process, which is applied in the deoxidation process of ladle and the field of deoxidation process, which can solve the problems of coarsening of bubbles, failure to achieve effective removal, and inapplicability of high deoxidation steel, so as to promote diffusion speed and fast reaction speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

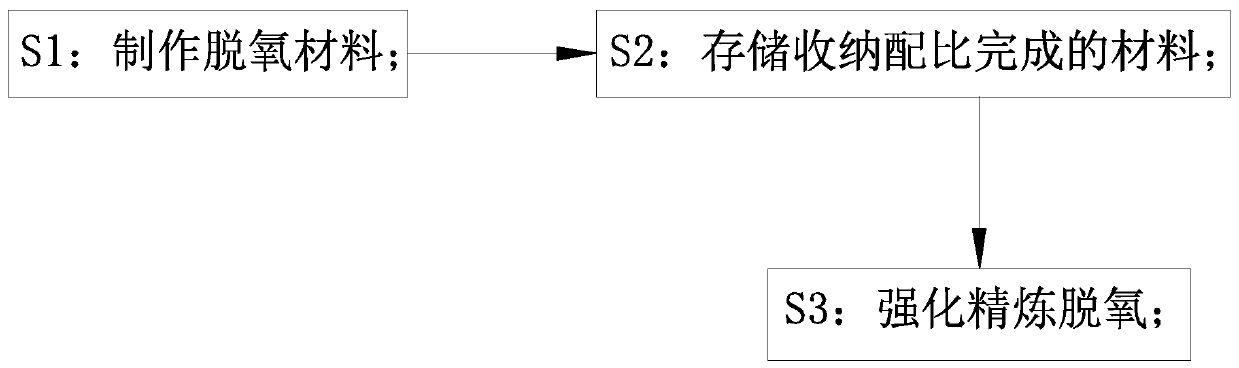

[0019] Such as figure 1 As shown, a kind of deoxidation process for electric furnace ladle provided by the present invention comprises the following steps:

[0020] S1: Make deoxidized material, grind limestone and aluminum to a particle size of less than 1mm, then mix the ground limestone and aluminum with graphite carbon with a carbon content of 90%, and press it into a diameter of 20-30mm with a dry powder briquetting machine Calcium carbonate carbon-aluminum balls, wherein the mass percentage of limestone accounts for 37-46% of the mass of carbon-aluminum balls, the mass percentage of aluminum accounts for 40-50% of the mass of carbon-aluminum balls, and the proportion of graphite carbon The mass percentage of the added ratio accounts for 4-7% of the carbon sphere mass, and the carbon content mass percentage in the middle of the calcium carbonate carbon sphere is controlled at 5-7%;

[0021] S2: Store and store the materials that have been proportioned, and vacuum pack th...

no. 2 example

[0026] Based on the deoxidation process for the electric furnace ladle provided by the first embodiment of the present invention, the difference of the deoxidation process for the electric furnace ladle provided by the second embodiment of the present invention is that the diameter is 26mm by using a dry powder briquetting machine Calcium carbonate carbon-aluminum balls, wherein the mass percentage of limestone accounts for 37-46% of the mass of carbon-aluminum balls, the mass percentage of aluminum accounts for 40-50% of the mass of carbon-aluminum balls, and the proportion of graphite carbon The mass percentage of the added ratio accounts for 4-7% of the mass of the carbon spheres, and the mass percentage of carbon content in the middle of the calcium carbonate carbon spheres is controlled at 5-7%.

no. 3 example

[0028] Based on the deoxidation process for the electric furnace ladle provided by the second embodiment of the present invention, the difference of the deoxidation process for the electric furnace ladle provided by the first embodiment of the present invention is that a dry powder briquetting machine is used to press into a diameter of 20 -30mm calcium carbonate carbon-aluminum balls, wherein the mass percentage of limestone accounts for 44% of the mass of carbon-aluminum balls, the mass percentage of aluminum accounts for 50% of the mass of carbon-aluminum balls, and the mass percentage of graphite carbon The mass percentage of the carbon sphere accounts for 6% of the mass of the carbon sphere, and the mass percentage of the carbon content in the middle of the calcium carbonate carbon sphere is controlled at 5-7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com