Florfenicol powder for improving water solubility as well as preparation method and application of florfenicol powder

A technology of florfenicol and water solubility, which is applied in the fields of improving water solubility of florfenicol powder and its preparation and application, and can solve problems such as poor curative effect, increased biological resistance, poor water solubility of florfenicol, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

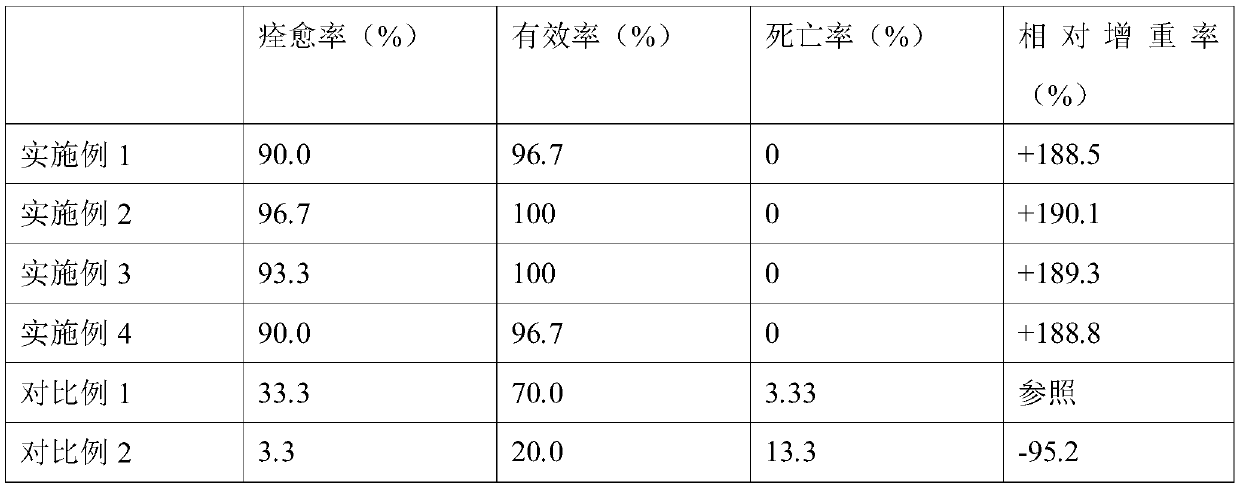

Examples

Embodiment 1

[0022] According to parts by weight, it consists of 10 parts of florfenicol powder, 5 parts of citric acid, 3 parts of polyvinylpyrrolidone PVPK30, 70 parts of lactose, 2 parts of sodium lauryl sulfate, 5 parts of polyethylene glycol 6000, 2 parts Trimethoprim lactate and 3 parts of palm oil form Florfenicol powder.

[0023] A preparation method for improving water-soluble florfenicol powder, comprising the steps of:

[0024] 1) Weighing 5 parts of polyethylene glycol 6000, 3 parts of palm oil, 110 parts of distilled water and dissolving 10 parts of florfenicol powder at 53 degrees Celsius to obtain a mixture 1;

[0025] 2) Add 3 parts of polyvinylpyrrolidone PVPK30, 70 parts of lactose, 2 parts of sodium lauryl sulfate, and 2 parts of trimethoprim lactate to mixture 1, stir and dissolve at 53 degrees Celsius, and then spray dry to obtain mixture 2, Pass through a 40 mesh sieve;

[0026] 3) Add 5 parts of citric acid to mixture 2, mix evenly, and pass through a 40-mesh sieve...

Embodiment 2

[0029] According to parts by weight, it consists of 10 parts of florfenicol powder, 4 parts of citric acid, 3 parts of polyvinylpyrrolidone PVPK30, 69 parts of lactose, 3 parts of sodium lauryl sulfate, 5 parts of polyethylene glycol 6000, 3 parts Trimethoprim lactate and 3 parts of palm oil form Florfenicol powder.

[0030] A preparation method for improving water-soluble florfenicol powder, comprising the steps of:

[0031] 1) Weighing 5 parts of polyethylene glycol 6000, 3 parts of palm oil, 110 parts of distilled water and dissolving 10 parts of florfenicol powder at 53 degrees Celsius to obtain a mixture 1;

[0032] 2) Add 3 parts of polyvinylpyrrolidone PVPK30, 69 parts of lactose, 3 parts of sodium lauryl sulfate, and 3 parts of trimethoprim lactate to mixture 1, stir and dissolve at 53 degrees Celsius, and then spray dry to obtain mixture 2, Pass through a 40 mesh sieve;

[0033] 3) Add 4 parts of citric acid to mixture 2, mix evenly, and pass through a 40-mesh sieve...

Embodiment 3

[0036] According to parts by weight, it consists of 10 parts of florfenicol powder, 5 parts of citric acid, 3 parts of polyvinylpyrrolidone PVPK30, 69 parts of lactose, 2 parts of sodium lauryl sulfate, 5 parts of polyethylene glycol 6000, 3 parts Trimethoprim lactate and 3 parts of palm oil form Florfenicol powder.

[0037] A preparation method for improving water-soluble florfenicol powder, comprising the steps of:

[0038] 1) Weighing 5 parts of polyethylene glycol 6000, 3 parts of palm oil, 110 parts of distilled water and dissolving 10 parts of florfenicol powder at 53 degrees Celsius to obtain mixture 1;

[0039] 2) Add 3 parts of polyvinylpyrrolidone PVPK30, 69 parts of lactose, 2 parts of sodium lauryl sulfate, and 3 parts of trimethoprim lactate to mixture 1, stir and dissolve at 53 degrees Celsius, and then spray dry to obtain mixture 2, Pass through a 40-mesh sieve; 3) Add 5 parts of citric acid to the mixture 2, mix evenly, and pass through a 40-mesh sieve to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solubility (mass) | aaaaa | aaaaa |

| solubility (mass) | aaaaa | aaaaa |

| solubility (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com