Ultra-high-temperature safe lithium ion battery electrolytic solution and lithium ion battery using electrolytic solution

A lithium-ion battery and electrolyte technology, applied in the field of lithium-ion batteries, can solve the problems of reducing ion conductivity, decreasing ion conductivity, and high viscosity, and achieving the effects of meeting performance requirements, improving thermal stability, and excellent safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

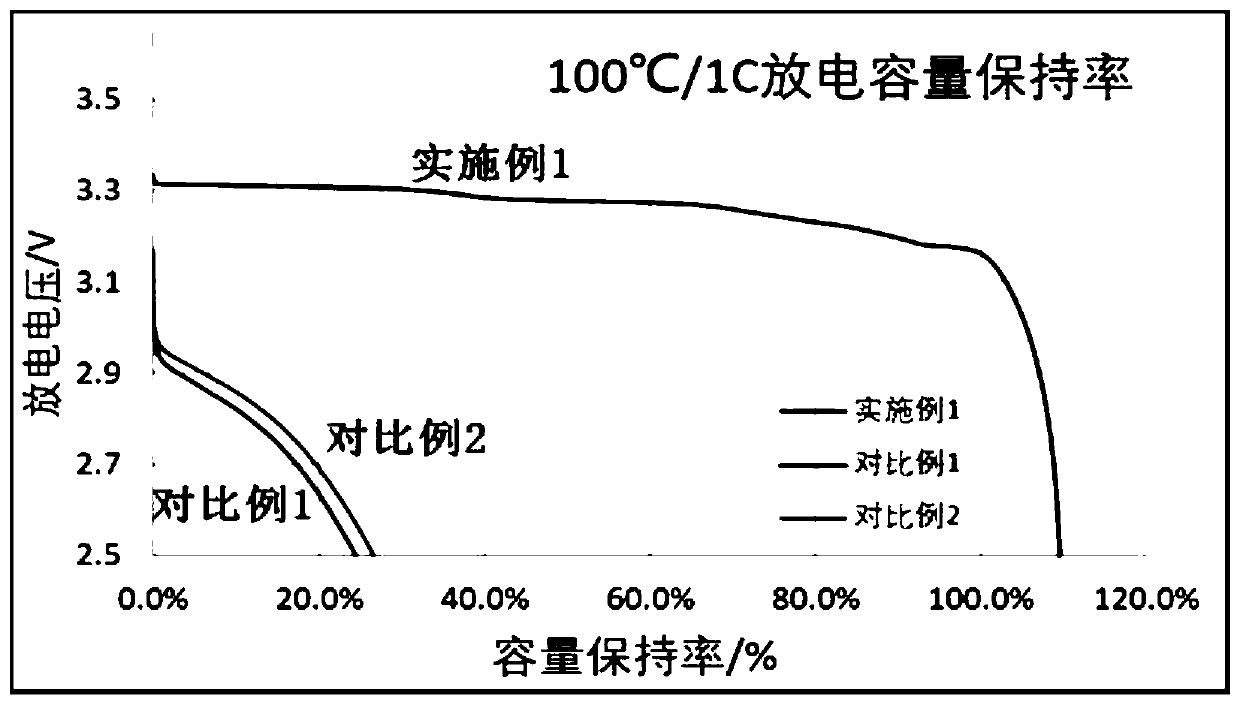

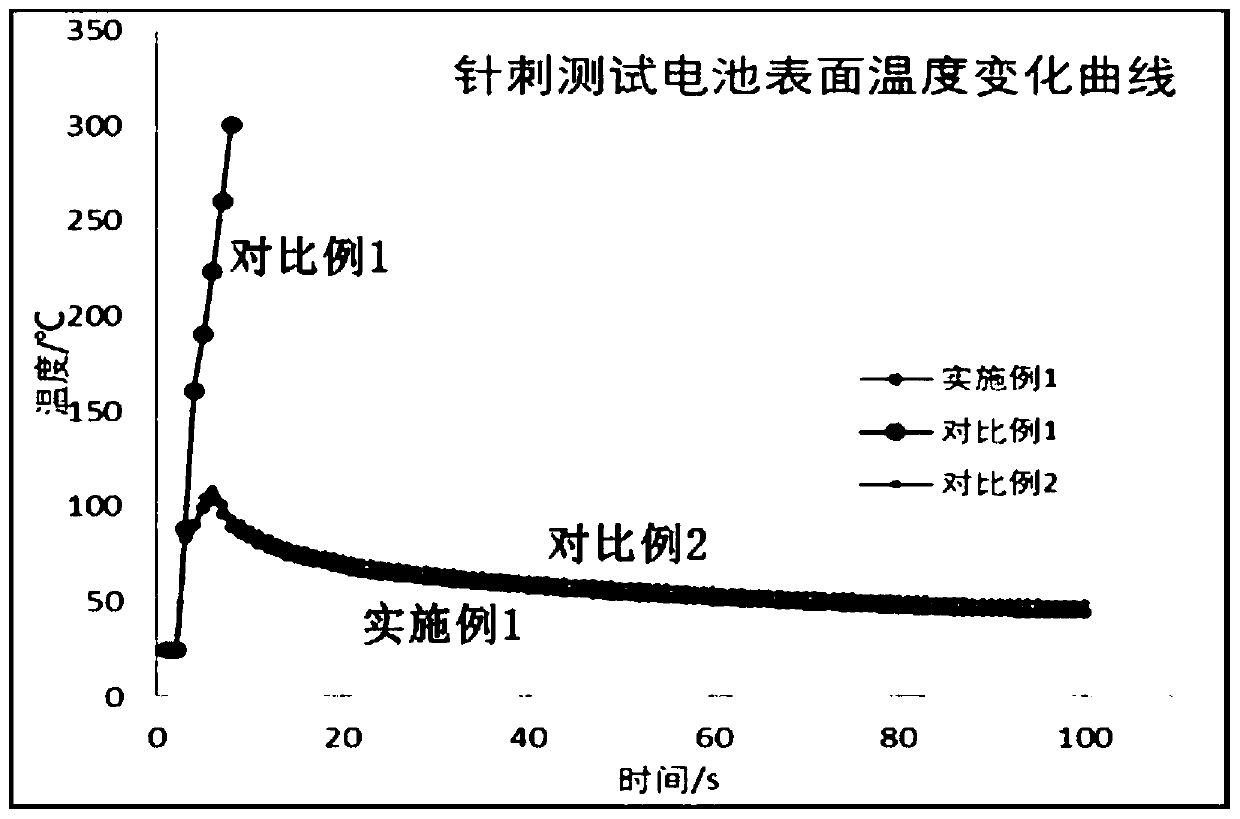

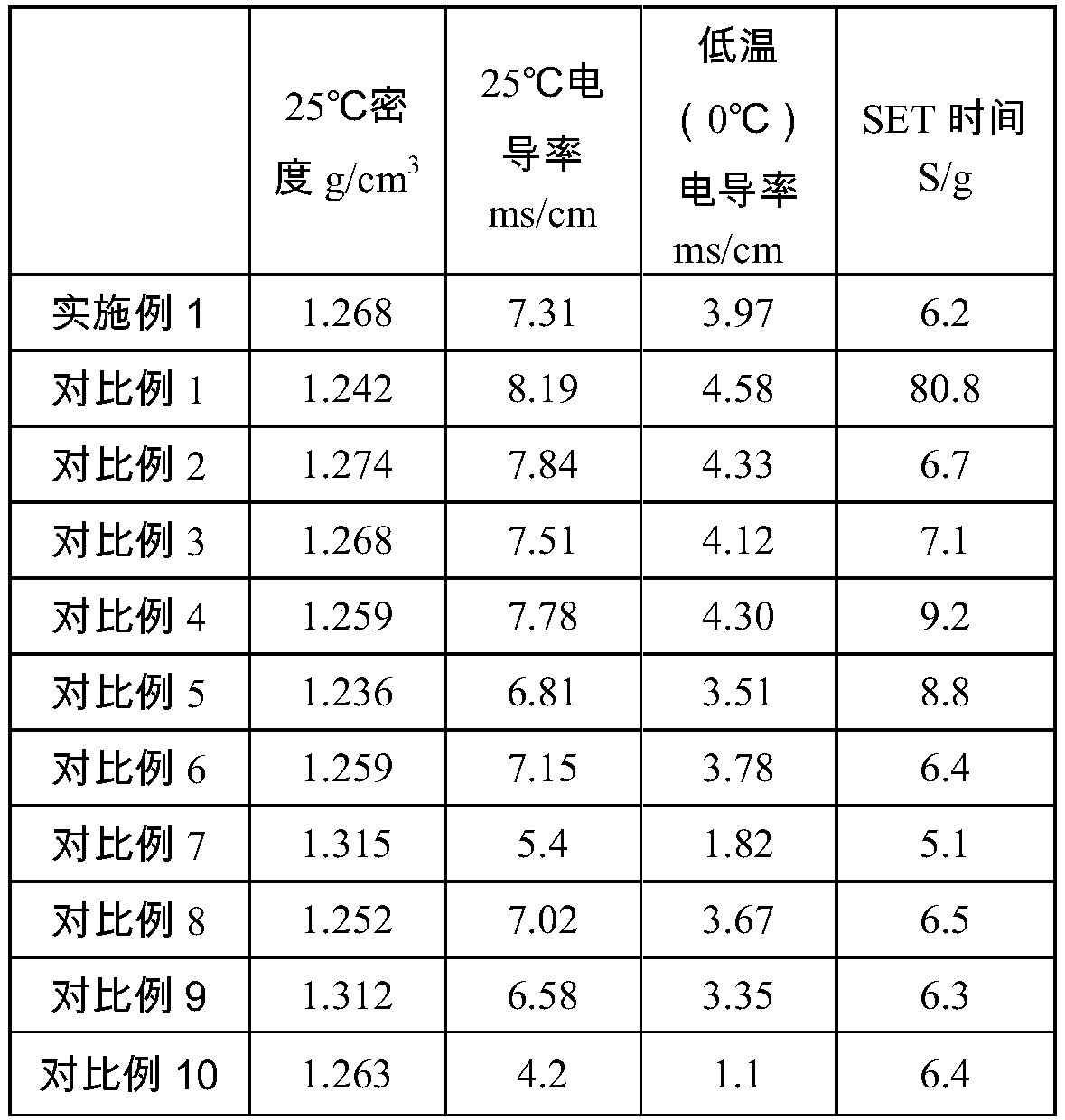

[0026] An ultra-high-temperature and high-safety lithium-ion battery electrolyte. The lithium salt is lithium trifluoromethanesulfonimide (LiTFSI). The lithium salt accounts for 13% of the mass fraction of the electrolyte. If LiTFSI is converted into a mole fraction, it is about 0.6mol / L . Organic solvents are ethylene carbonate (EC), propylene carbonate (PC), diethyl carbonate (DEC), 1,1,2,2-tetrafluoroethyl-2,2,3,3-tetrafluoropropyl Ether, four solvents are mixed according to the mass ratio of 3:1:6:1. The high-temperature film-forming additives are vinyl sulfate (DTD), 1,3-propene sultone (PST), lithium fluorophosphate (LiPF 2 o 2 ), film-forming additives account for 3% of the mass fraction of the entire electrolyte, DTD, PST, LiPF 2 o 2 The mass ratio is 2:1:2. The flame retardant additive in the electrolyte is ethoxy (pentafluoro)cyclotriphosphazene, and the added amount of the flame retardant accounts for 6% of the mass fraction of the entire electrolyte.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com