High-speed communication cable

A high-speed communication and cable technology, applied in the direction of communication cables, cables, insulated cables, etc., can solve the problems of low cut-off frequency, increase the attenuation of electrical signals, etc., and achieve high cut-off frequency, low delay difference, and excellent shielding attenuation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

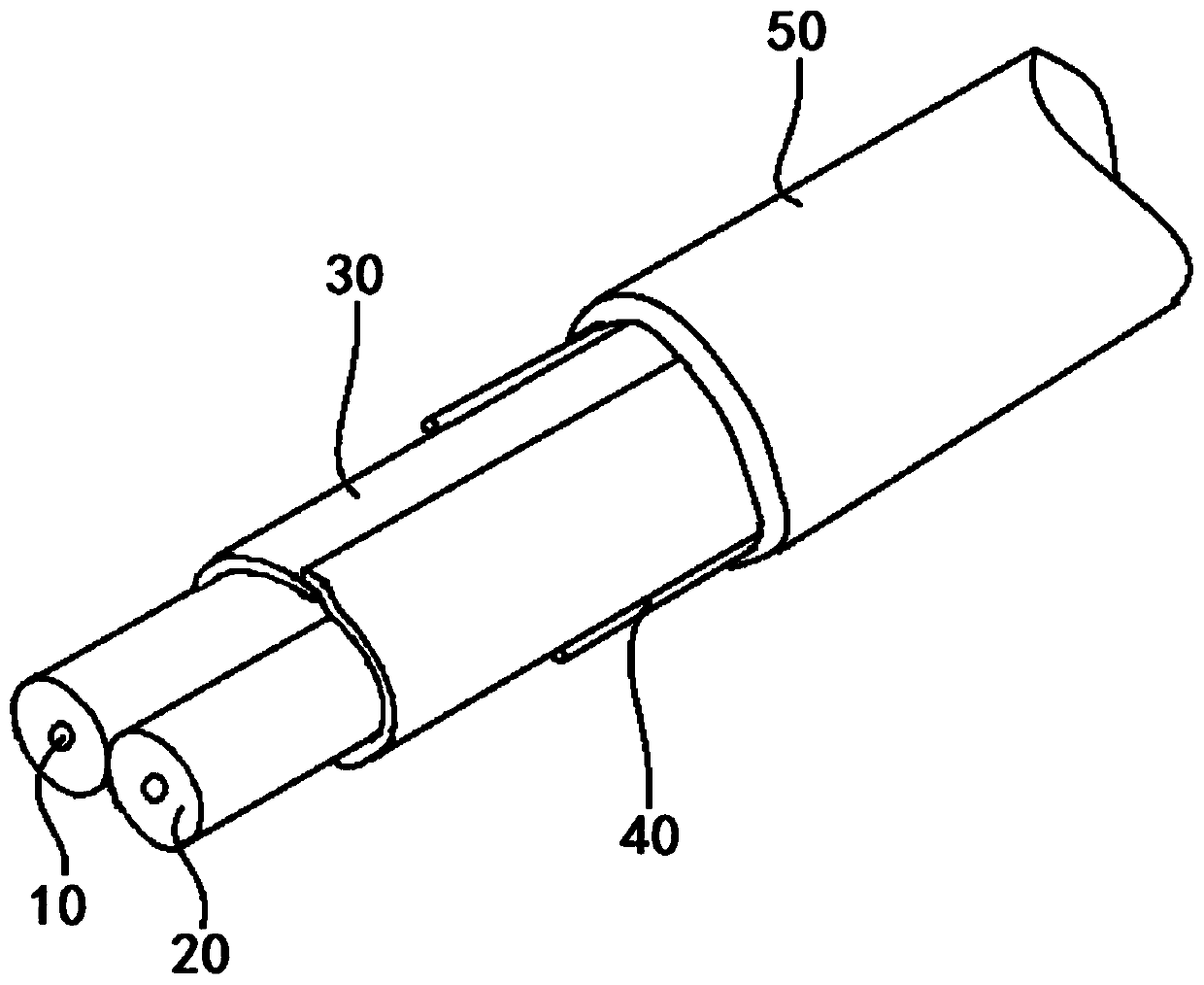

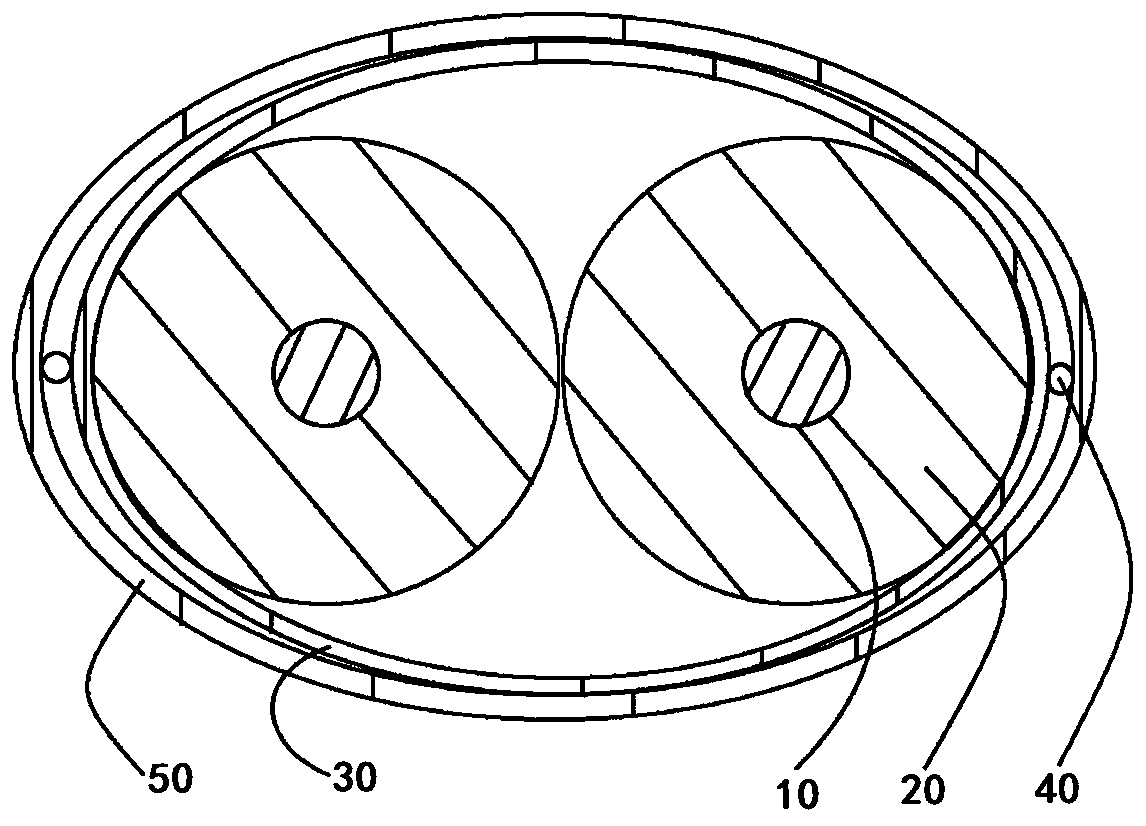

[0037] This embodiment provides a Figure 1-2 The high-speed communication cable with the structure shown includes a pair of conductors 10 arranged side by side in parallel. The type of conductor 10 is solid silver-plated copper with an outer diameter of 0.285±0.02mm; the periphery of each conductor 10 is covered with an insulating material 20, The insulating material 20 is polyethylene, and its outer diameter is 0.80±0.02mm; the periphery of the insulating material 20 is coated with a composite shielding film 30 and an outer sheath 50 in sequence, between the composite shielding film 30 and the outer sheath 50 Two parallel drain lines 40 are provided. The composite shielding film 30 wraps the insulating material 20 along the length direction of the insulating material 20 , and the ends of the composite shielding film 30 are partially overlapped and bonded by conductive glue. The material of the outer sheath is hot-melt polyester tape, the height of the outer sheath is 0.99±0...

Embodiment 2

[0039] This embodiment provides a Figure 1-2 The high-speed communication cable with the structure shown includes a pair of conductors 10 arranged side by side in parallel. The type of conductor 10 is solid silver-plated copper with an outer diameter of 0.285±0.02mm; the periphery of each conductor 10 is covered with an insulating material 20, The insulating material 20 is polyethylene, and its outer diameter is 0.80±0.02mm; the periphery of the insulating material 20 is coated with a composite shielding film 30 and an outer sheath 50 in sequence, between the composite shielding film 30 and the outer sheath 50 Two parallel drain lines 40 are provided. The composite shielding film 30 wraps the insulating material 20 along the length direction of the insulating material 20 , and the ends of the composite shielding film 30 are partially overlapped and bonded by conductive glue. The material of the outer sheath is hot-melt polyester tape, the height of the outer sheath is 0.99±0...

Embodiment 3

[0041] This embodiment provides a Figure 1-2 The high-speed communication cable with the structure shown includes a pair of conductors 10 arranged side by side in parallel. The type of conductor 10 is solid silver-plated copper with an outer diameter of 0.285±0.02mm; the periphery of each conductor 10 is covered with an insulating material 20, The insulating material 20 is polyethylene, and its outer diameter is 0.80±0.02mm; the periphery of the insulating material 20 is coated with a composite shielding film 30 and an outer sheath 50 in sequence, between the composite shielding film 30 and the outer sheath 50 Two parallel drain lines 40 are provided. The composite shielding film 30 wraps the insulating material 20 along the length direction of the insulating material 20 , and the ends of the composite shielding film 30 are partially overlapped and bonded by conductive glue. The material of the outer sheath is hot-melt polyester tape, the height of the outer sheath is 0.99±0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com