Epoxy resin system compatible with liquid oxygen for prepregs and preparation method of epoxy resin system

A technology of epoxy resin system and liquid epoxy resin, which is applied in the field of epoxy resin system and its preparation, can solve the problems of restricting the development of composite fuel storage tanks, improve the compatibility of liquid oxygen, enhance the flame retardant effect, The effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

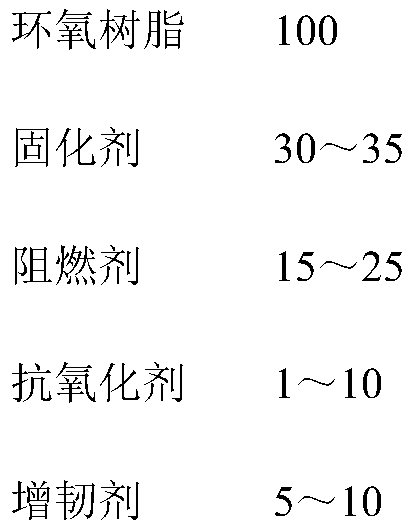

[0036] ①Mix 70 parts of TDE-85 and 5 parts of AG-80 and carry out vacuum distillation treatment, then heat it to 120°C, then add 25 parts of solid epoxy E20 and stir evenly;

[0037] ② Add 10 parts of organophosphorus flame retardant TAD to the above epoxy resin mixture and react at 140°C for 1 hour to obtain phosphorus flame retardant grafted epoxy resin;

[0038] ③Reduce the temperature of the above reaction product to 100°C, add 1 part of antioxidant XH-245, 5 parts of inorganic flame retardant 3.5 water zinc borate, and 8 parts of toughening agent polyurethane to the resin, stir and mix evenly, and carry out vacuum distillation treatment ;

[0039] ④At 100°C, add 33 parts of the curing agent diaminodiphenylsulfone that has been subjected to vacuum distillation to the above epoxy resin mixture, stir and mix evenly, and vacuumize to remove air bubbles;

[0040] ⑤ The above epoxy resin system is lowered to room temperature, and the obtained product can be used for the prepar...

Embodiment 2

[0043] ①Mix 70 parts of TDE-85 and 5 parts of AG-80 and carry out vacuum distillation treatment, then heat it to 120°C, then add 25 parts of solid epoxy E12 and stir evenly;

[0044] ② Add 10 parts of organophosphorus flame retardant TAD to the above epoxy resin mixture and react at 140°C for 1 hour to obtain phosphorus flame retardant grafted epoxy resin;

[0045] ③Reduce the temperature of the above reaction product to 110°C, add 5 parts of antioxidant BASF1010 and 5 parts of antioxidant BASF168, 10 parts of inorganic flame retardant magnesium hydroxide, and 8 parts of toughening agent polyurethane, add resin and mix, fully stir and mix evenly;

[0046] ④At 100°C, add 33 parts of curing agent diaminodiphenyl sulfone to the epoxy resin mixture after vacuum distillation, fully stir and mix evenly, and put the above mixed product into a vacuum oven for degassing treatment;

[0047] ⑤ The above epoxy resin system is lowered to room temperature, and the obtained product can be us...

Embodiment 3

[0050] ①Mix 70 parts of TDE-85 and 10 parts of AG-80 and carry out vacuum distillation treatment, then heat it to 110°C, then add 20 parts of solid epoxy E03, and stir evenly;

[0051] ② Add 10 parts of organophosphorus flame retardant TAD to the above epoxy resin mixture and react at 140°C for 1 hour to obtain phosphorus flame retardant grafted epoxy resin;

[0052] ③Reduce the temperature of the above reaction product to 100°C, add 5 parts of antioxidant XH-245, 5 parts of inorganic flame retardant boehmite, and 8 parts of toughening agent polyurethane into the resin and mix, fully stir and mix evenly;

[0053] ④At 100°C, add 35 parts of curing agent diaminodiphenyl sulfone to the epoxy resin mixture after vacuum distillation, fully stir and mix evenly, and put the above mixed product into a vacuum oven for degassing treatment;

[0054] ⑤ The above epoxy resin system is lowered to room temperature, and the obtained product can be used for the preparation of carbon fiber prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com