A preparation method of phosphorus-containing silicon hybrid nano-hydroxides that improve the application of epoxy resins under liquid oxygen

A technology of oxyhydroxide and epoxy resin solution, which is applied in the field of preparation of phosphorus-containing silicon hybrid nano-oxyhydroxide, can solve the problems of limited energy absorption and lower mechanical properties of the resin system, and achieve strong thermal decomposition ability and cost-effective products High, high thermal stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

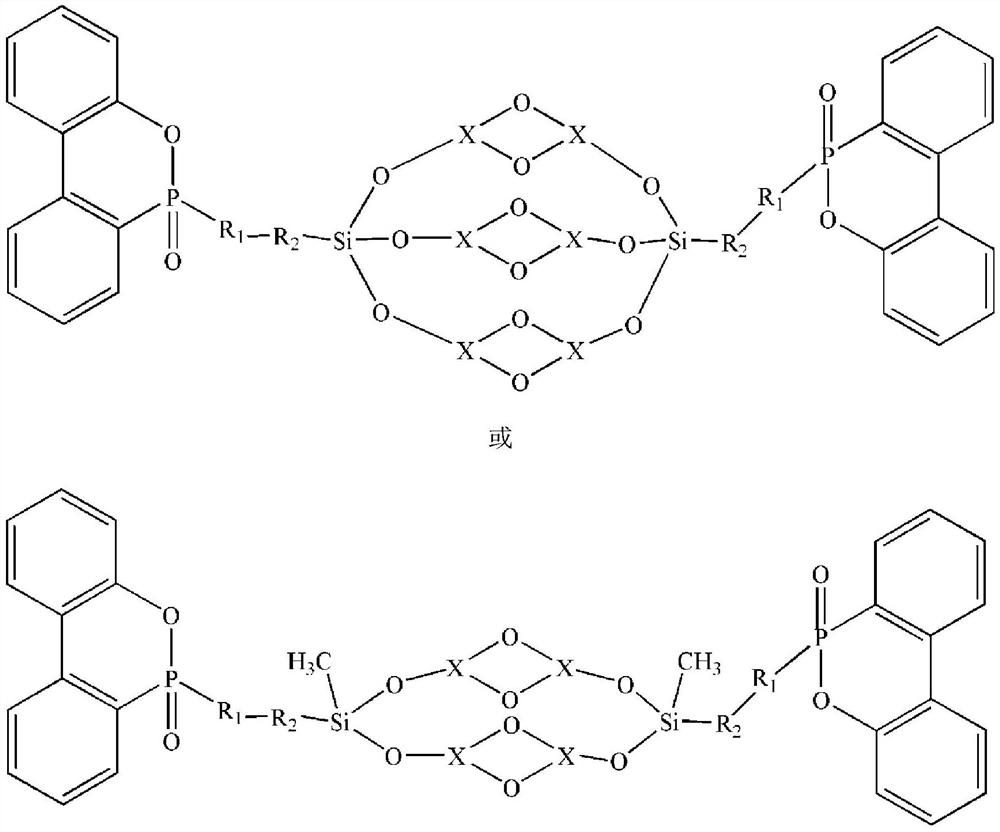

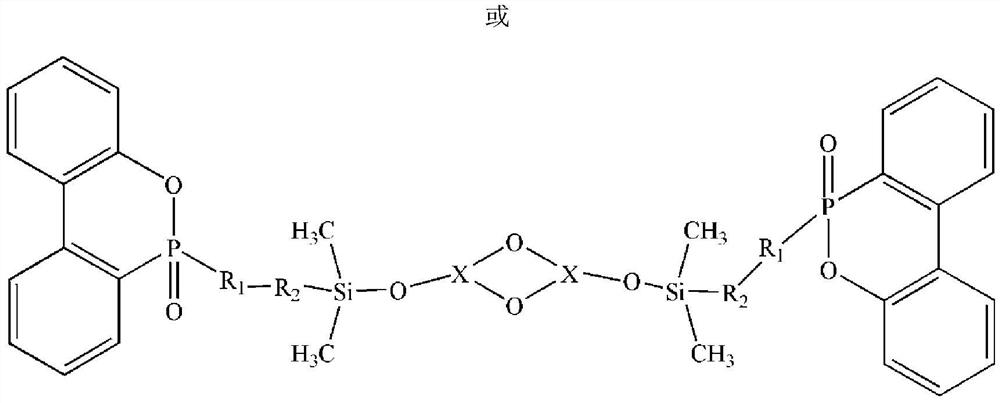

Method used

Image

Examples

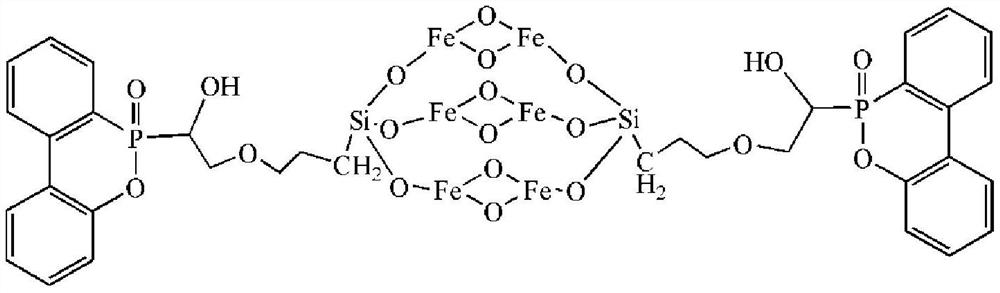

Embodiment 1

[0034] Pour 1 mole of (3-oxiranylmethoxypropyl) trimethoxysilane and 1.1 moles of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide into a three-necked flask, Then it was dissolved with 350ml of ethanol, condensed and refluxed under nitrogen protection atmosphere, while heating and stirring, the heating temperature was 70°C, and the reaction time was 14h, and the reaction liquid was a clear and transparent solution. The mass (g / ml) of the product in the above ethanol liquid was then determined by evaporation of the solvent. Add 1.32 g of nano-flaky ferric oxyhydroxide and ethanol solution containing 2.90 g of the above product into a beaker, then add 33 ml of water, stir at room temperature for 5 h, finally add 3 ml of concentrated ammonia water, stir at room temperature for 12 h, and mix the obtained liquid with fiber The membrane was washed with water and suction filtered until the solution reached neutrality, and then the filter cake was dried at 90°C for 8 hours, and the ...

Embodiment 2

[0037]Pour 1 mole of (3-glycidoxypropyl) methyldimethoxysilane and 1 mole of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide into a three-necked flask , then dissolved in 350ml of toluene, condensed and refluxed under a nitrogen atmosphere, while heating and stirring, the heating temperature was 95°C, and the reaction time was 12h. The reaction liquid was a clear and transparent solution. The mass (g / ml) of the product in the above toluene liquid was then determined by evaporation of the solvent. Add 1.32 g of nano-acicular manganese oxyhydroxide and toluene solution containing 5.28 g of the above product into a beaker, then add 40 ml of water, stir at room temperature for 7 hours, finally add 7 ml of concentrated ammonia water, and stir at room temperature for 18 hours. The membrane was washed with water and suction filtered until the solution reached neutrality, and then the filter cake was dried at 90°C for 8 hours, and the obtained powder was the target product containi...

Embodiment 3

[0040] 1 mole of (3-oxiranylmethoxypropyl) trimethoxysilane and 0.9 moles of 10-(2,5-dihydroxyphenyl)-10-hydrogen-9-oxa-10-phosphaphenanthrene -10-Oxide was poured into a three-necked flask, then dissolved in 400ml of ethanol, condensed and refluxed under a nitrogen atmosphere, while heating and stirring, the heating temperature was 70°C, and the reaction time was 18h. The reaction liquid was a clear and transparent solution. The mass (g / ml) of the product in the above ethanol liquid was then determined by evaporation of the solvent. Add 1.32g of nano-spherical cobalt oxyhydroxide and ethanol solution containing 5.28g of the above product into a beaker, then add 35ml of water, stir at room temperature for 7h, finally add 10ml of concentrated ammonia water, stir at room temperature for 18h, and filter the obtained liquid with a fiber membrane Wash and filter with water until the solution reaches neutrality, then dry the filter cake at 90°C for 8 hours, and the obtained powder i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com