A tough epoxy resin system compatible with liquid oxygen

A tough epoxy resin and epoxy resin technology, applied in the fields of chemical industry and materials, can solve the problems of liquid oxygen incompatibility, material performance degradation, etc., and achieve the effect of good toughness and excellent liquid oxygen compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A flexible epoxy resin system compatible with liquid oxygen prepared by:

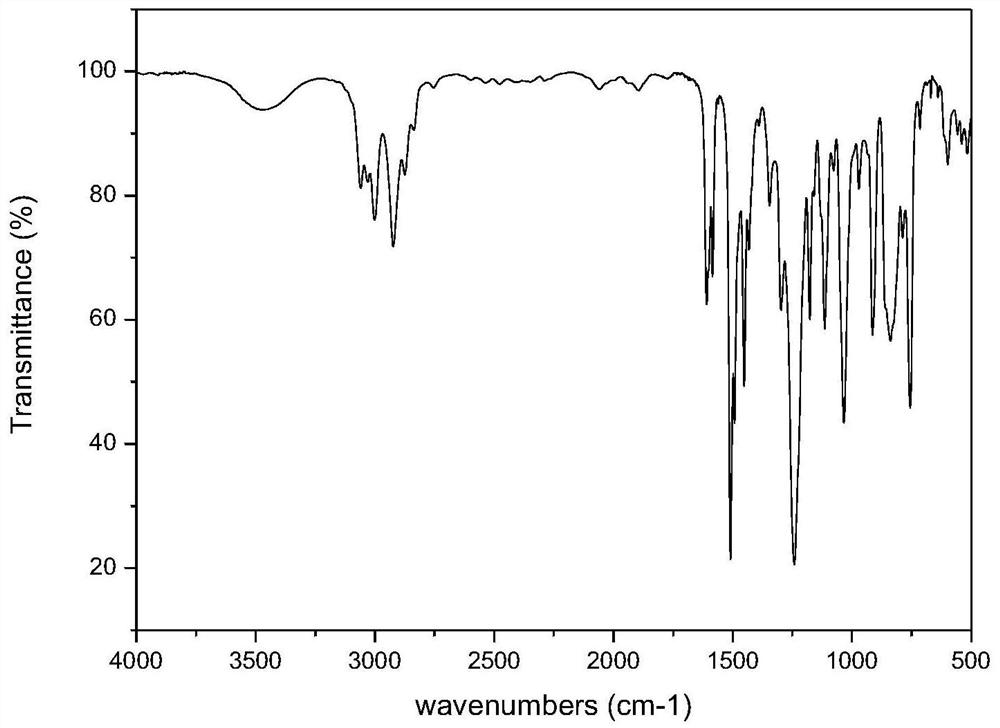

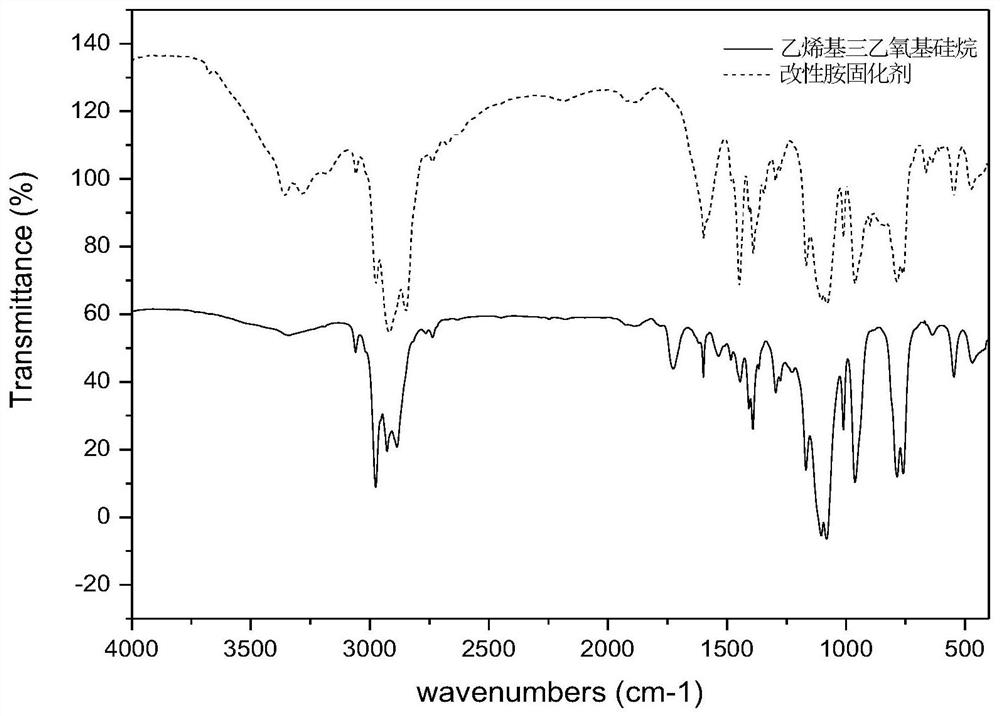

[0027] 1) Preparation of modified amine curing agent: at a temperature of 80°C, slowly add vinyl triethoxysilane to the alicyclic amine curing agent, the mixture of alicyclic amine curing agent and vinyl triethoxysilane The molar ratio is 1:1, and the temperature of the reaction system is controlled at 80°C during the dropping process. After the dropping is completed, it is kept at 80°C for 2 hours to obtain a modified amine curing agent;

[0028] 2) Preparation of modified epoxy resin: at a temperature of 120°C, add DOPO to the epoxy resin for stirring (the mass ratio of DOPO to epoxy resin is 1:13), and after DOPO is completely dissolved, raise the temperature to 160°C and keep it warm 5h, obtain modified epoxy resin;

[0029] 3) Preparation of liquid oxygen compatible epoxy resin system: mix 100 parts of modified epoxy resin with 68 parts of modified amine curing agent in parts by mass, gel a...

Embodiment 2

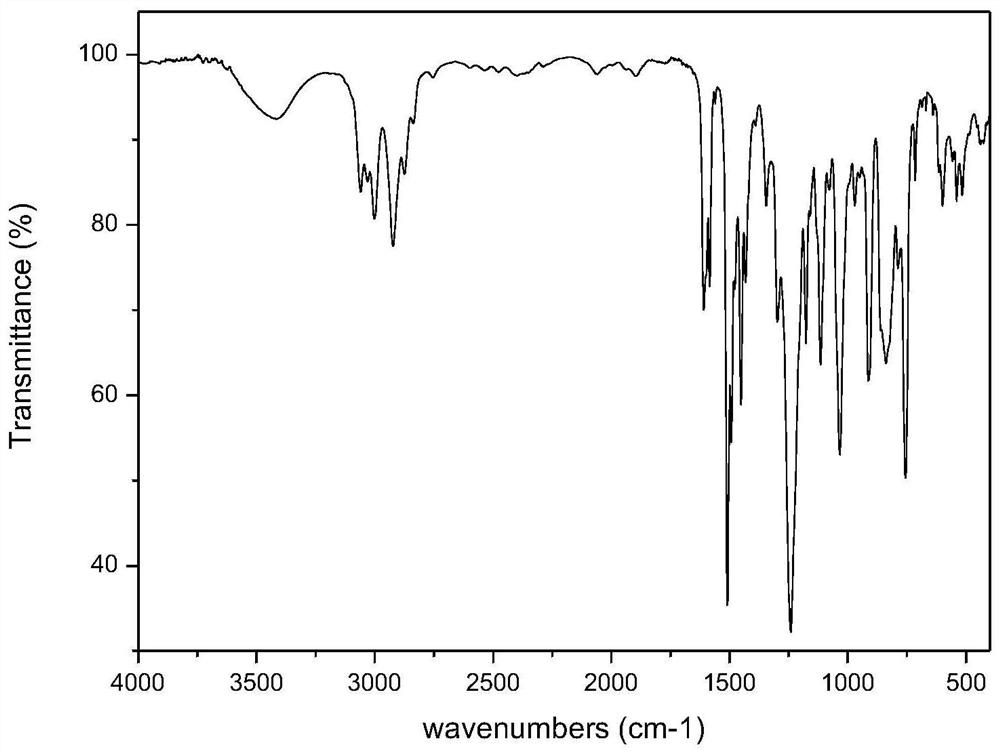

[0032] A tough epoxy resin system compatible with liquid oxygen and a preparation method thereof, the preparation method is as follows:

[0033] 1) Preparation of modified amine curing agent: at a temperature of 80°C, slowly add vinyl triethoxysilane to the alicyclic amine curing agent, the mixture of alicyclic amine curing agent and vinyl triethoxysilane The molar ratio is 1:2, and the temperature of the reaction system is controlled at 80°C during the dropping process. After the dropping is completed, it is kept at 80°C for 2 hours to obtain a modified amine curing agent;

[0034] 2) Preparation of modified epoxy resin: at a temperature of 120°C, add DOPO to the epoxy resin for stirring (the mass ratio of DOPO to epoxy resin is 1:13), and after DOPO is completely dissolved, raise the temperature to 160°C and keep it warm 5h, obtain modified epoxy resin;

[0035] 3) Preparation of liquid oxygen compatible epoxy resin system: mix 100 parts of modified epoxy resin with 102 par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com