A high-temperature synthetic organic heat carrier pulse blending production device and production method

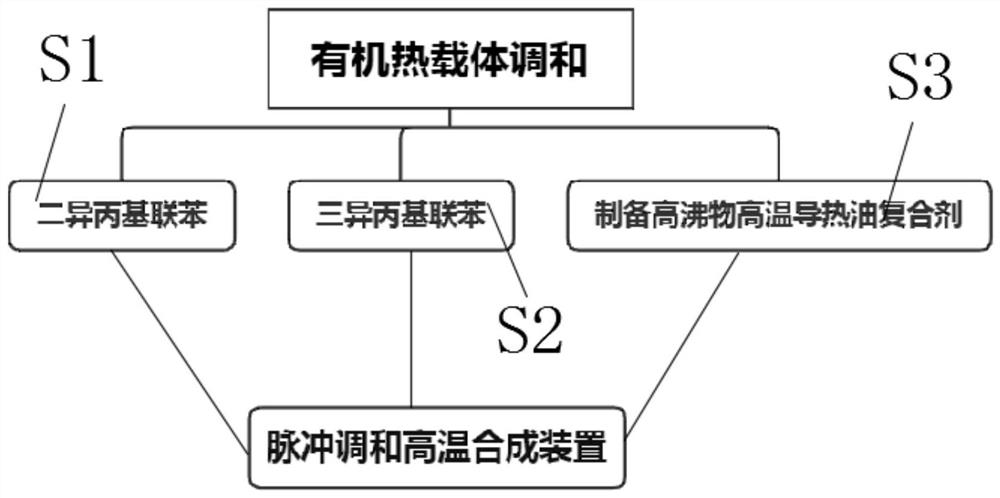

A production device and high-temperature technology, which is applied in the field of high-temperature synthetic organic heat carrier pulse blending production device, can solve the problems of complex production process, high kinematic viscosity and low production efficiency, and achieve high purity, low kinematic viscosity and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

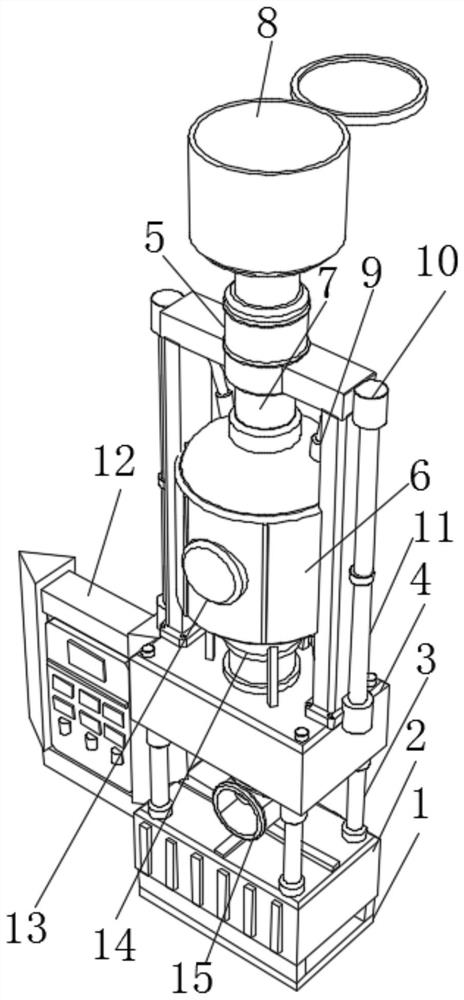

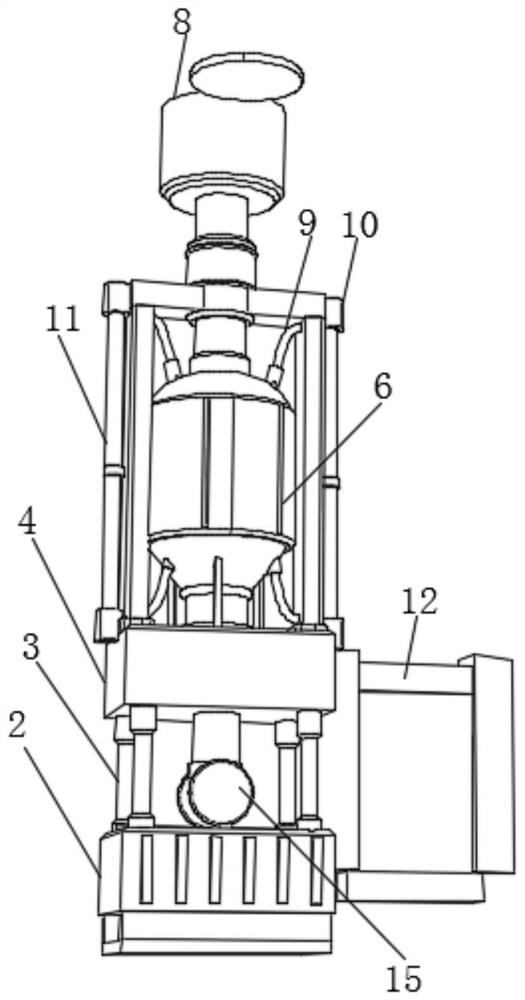

[0040] see Figure 1-5 , the present invention provides the following technical solutions: a high-temperature synthetic organic heat carrier pulse blending production device, including a base 1, a square vibrator 2 is fixedly installed on the top of the base 1, and the four corners of the top of the vibrator 2 are all vertical The limit guide rods 3 are fixedly installed, and the tops of the four limit guide rods 3 are fixedly supported with a support plate 4, and the two sides of the middle part of the support plate 4 are fixedly installed with tank racks 5, and the middle part of the tank rack 5 is provided with tank placement slots , the inside of the tank body placement tank is fixedly installed with a tank body 6 for pulse processing the organic heat carrier, the top middle of the tank body 6 is provided with a feed port, and the top of the feed port is interspersed with a connecting pipe 7, The top end of the connecting pipe 7 passes through the middle part of the tank f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com