Multifunctional supersonic flame spraying method and its intelligent control system

A supersonic flame and multi-functional technology, applied in the direction of coating, injection device, liquid injection device, etc., can solve the problems of many control objects and complicated process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

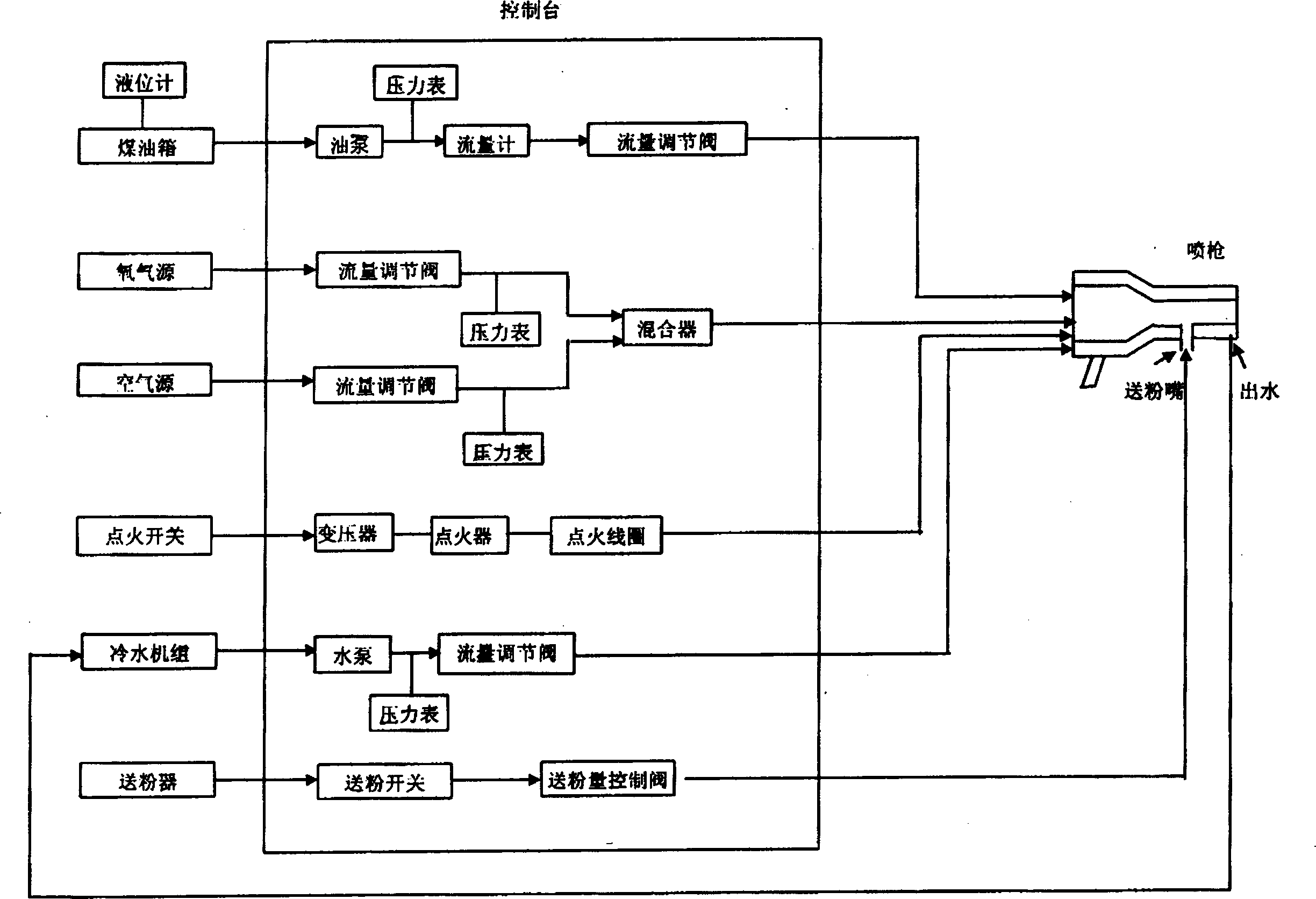

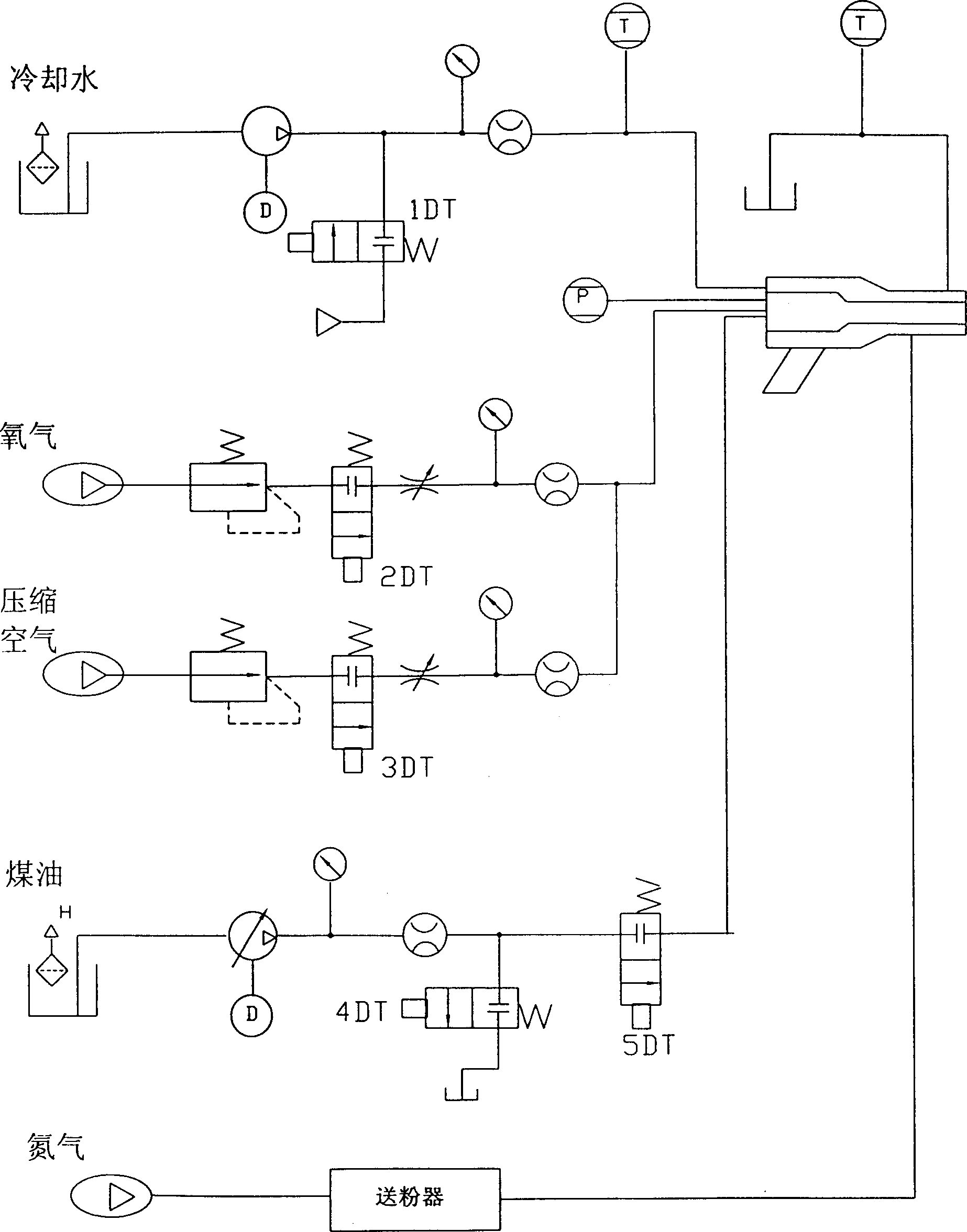

[0033] The working program of the present invention is as follows: pre-spray inspection: according to the pre-spray inspection module on the console, press the corresponding switch to check the oil circuit, gas circuit and water circuit, and check whether the work of each circuit is normal. Spraying: There are two modes of operation for spraying, namely manual and automatic. In manual spraying, operate in the order of water supply, air supply, oil supply, ignition, and spraying. In automatic spraying, operate in the order of ignition and spraying. When spraying stops, operate in the reverse order of spraying.

[0034] Compared with the prior art, the present invention has the following advantages:

[0035] 1. The flying speed of particles is high, the impact kinetic energy is high, and the particle bonding is good. The sprayed coating has high bonding strength, low porosity, and dense coating.

[0036] 2. The flight time of particles in the atmosphere is short, and the oxide co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com