Ni-doped CuCoMnOx spinel structure solar selective absorption coating and preparation method

A spinel structure, selective absorption technology, applied in solar thermal power generation, coating, metal material coating technology, etc., to achieve excellent emissivity and absorption rate, stable application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

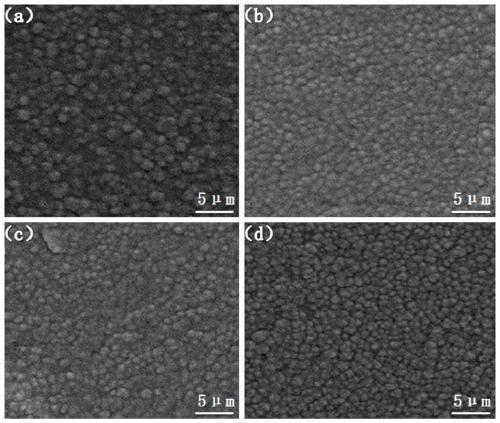

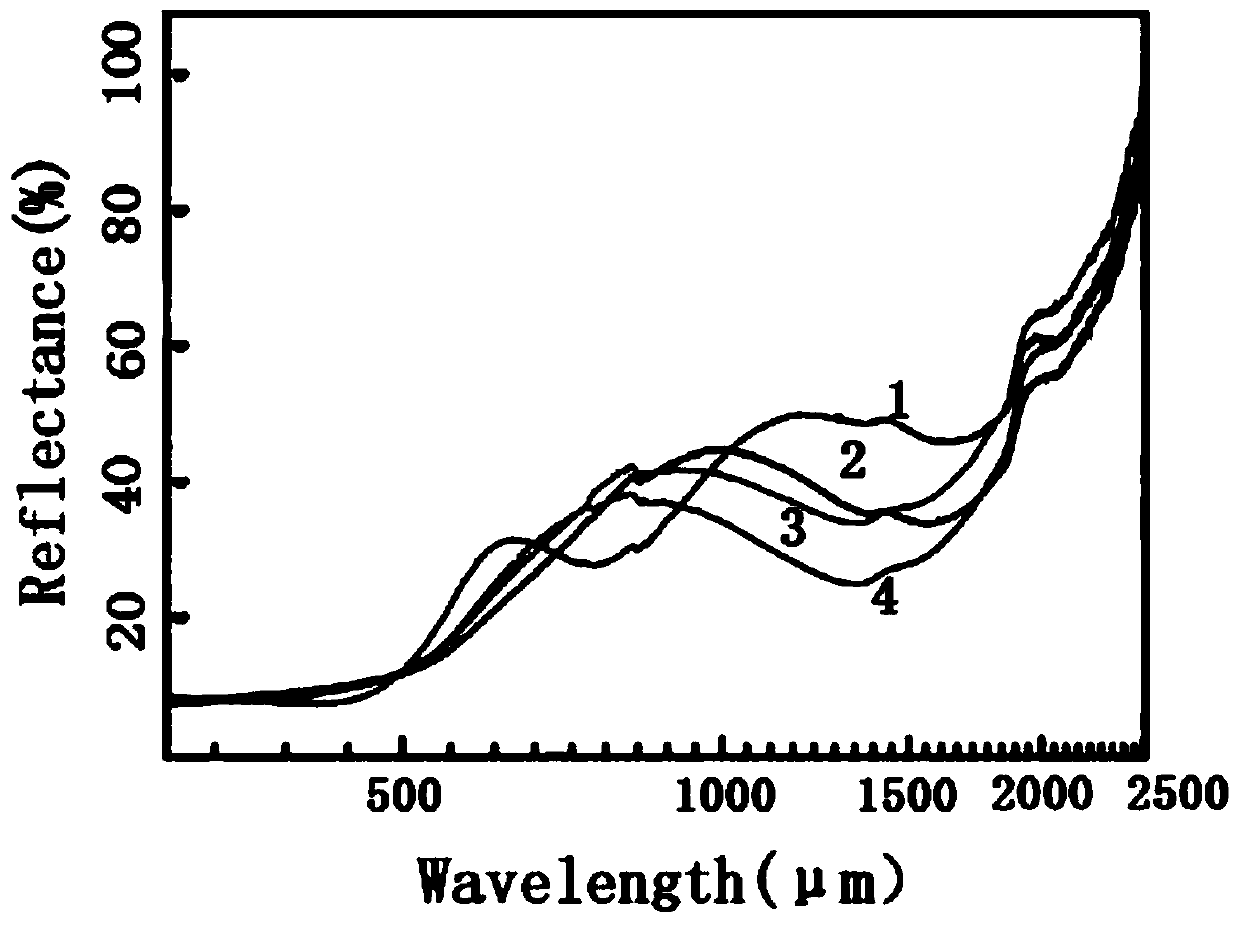

Embodiment 1

[0031] A Ni-doped CuCoMnO x The preparation method of the spinel structure solar energy selective absorption coating comprises the following steps:

[0032] (1) Substrate pretreatment: immerse the stainless steel substrate in pickling and degreasing solution, then ultrasonically wash it with sewage ethanol and deionized water for 15 minutes, and dry it for later use.

[0033](2) Ceramic target material preparation: use copper oxide powder with a particle size of 20 μm, cobalt oxide powder with a particle size of 20 μm, and manganese oxide powder with a particle size of 20 μm to mix according to a certain molar ratio, add polyvinyl alcohol for ball milling for 5 hours, granulate, sieve, The powder is placed in a mold and formed by cold isostatic pressing under a pressure of 15MPa, heated to 500°C for 2 hours, and then heated to 1000°C for sintering to obtain a ceramic target with a spinel structure.

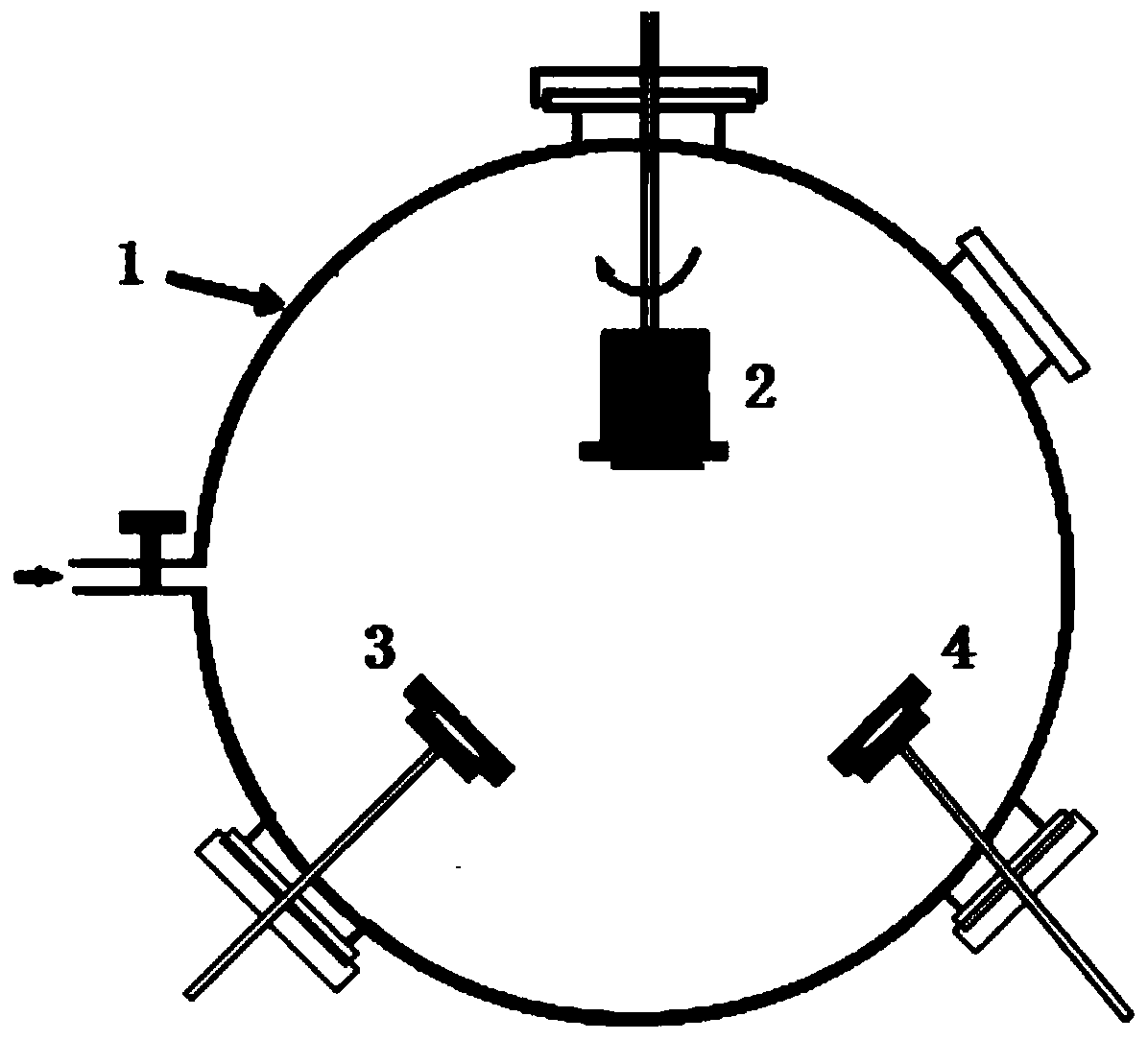

[0034] (3) Ion bombardment treatment: the substrate is placed on the rotatin...

Embodiment 2

[0038] A Ni-doped CuCoMnO x The preparation method of the spinel structure solar energy selective absorption coating comprises the following steps:

[0039] (1) Substrate pretreatment: immerse the aluminum substrate in pickling and degreasing solution, then ultrasonically wash with sewage ethanol and deionized water for 10 minutes, and dry for later use.

[0040] (2) Preparation of ceramic target material: use copper oxide powder with a particle size of 10 μm, cobalt oxide powder with a particle size of 20 μm, and manganese oxide powder with a particle size of 30 μm to mix according to a certain molar ratio, add polyvinyl alcohol for ball milling for 6 hours, granulate, sieve, The powder was placed in a mold and formed by cold isostatic pressing under a pressure of 20 MPa, the temperature was raised to 550°C for 3 hours, and then the temperature was raised to 1200°C for sintering to obtain a ceramic target with a spinel structure.

[0041] (3) Ion bombardment treatment: the s...

Embodiment 3

[0045] A Ni-doped CuCoMnO x The preparation method of the spinel structure solar energy selective absorption coating comprises the following steps:

[0046] (1) Substrate pretreatment: immerse the copper substrate in pickling and degreasing solution, then ultrasonically wash with sewage ethanol and deionized water for 10 minutes, and dry for later use.

[0047] (2) Preparation of ceramic target material: use copper oxide powder with a particle size of 30 μm, cobalt oxide powder with a particle size of 20 μm, and manganese oxide powder with a particle size of 10 μm to mix according to a certain molar ratio, add polyvinyl alcohol for ball milling for 7 hours, granulate, sieve, The powder was placed in a mold and formed by cold isostatic pressing under a pressure of 25 MPa, the temperature was raised to 600°C for 3 hours, and then the temperature was raised to 1100°C for sintering to obtain a ceramic target with a spinel structure.

[0048] (3) Ion bombardment treatment: the sub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com