Water-resistant high-strength inorganic silicate adhesive and preparation method thereof

An inorganic silicate and adhesive technology, applied in inorganic adhesives, adhesives, polymer adhesive additives, etc., can solve the problems of low adhesive strength, poor water resistance, etc., to improve mechanical strength, improve roughness, improve Enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

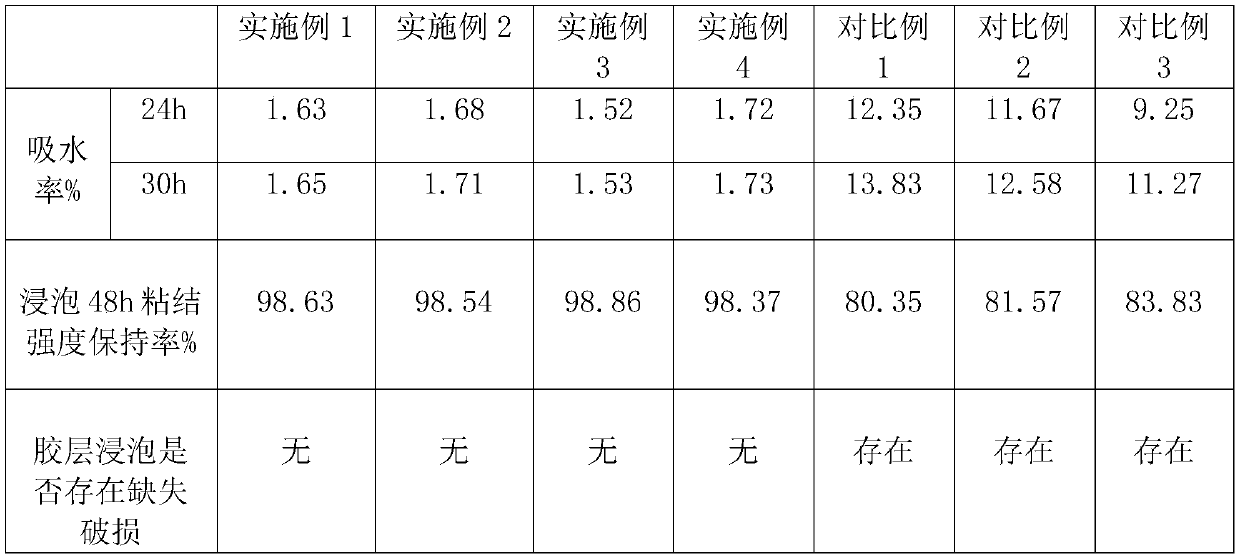

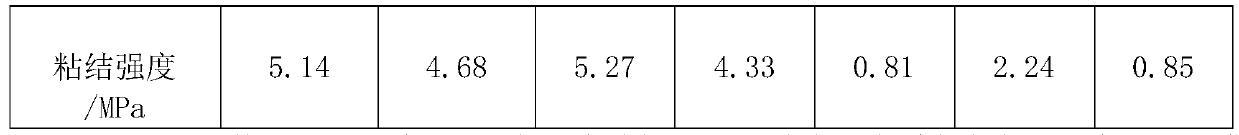

Examples

Embodiment 1

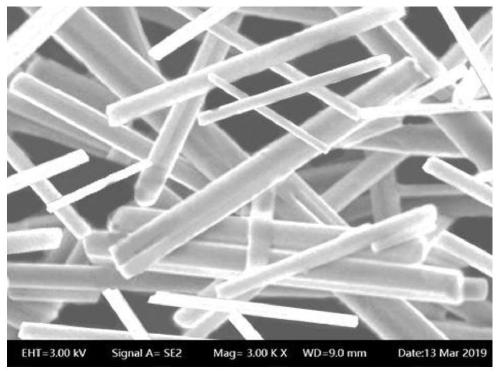

[0028] The preparation method of composite potassium hexatitanate whisker comprises the following steps:

[0029] Mix potassium carbonate, titanium dioxide and boric acid evenly and place them in a ball milling tank. The mass ratio of potassium carbonate to titanium dioxide is 1:5, and the mass ratio of potassium carbonate to boric acid is 1:0.2. Add absolute ethanol to the ball milling tank for ball milling 3h, dry, pass through a 150-mesh sieve to obtain a mixture, put the mixture in a muffle furnace and calcinate at 1000°C for 1h, cool to obtain potassium hexatitanate whiskers, add calcium chloride to deionized water, stir and dissolve to prepare The mass concentration is 5.0% calcium chloride aqueous solution, add potassium hexatitanate whisker and sodium lauryl sulfate to the calcium chloride aqueous solution, the mass ratio of potassium hexatitanate whisker and calcium chloride is 1:0.3, The amount of sodium lauryl sulfate added accounts for 0.5% of the mass concentratio...

Embodiment 2

[0037] The preparation method of composite potassium hexatitanate whisker comprises the following steps:

[0038] Mix potassium carbonate, titanium dioxide and boric acid evenly and place them in a ball milling tank. The mass ratio of potassium carbonate to titanium dioxide is 1:3, and the mass ratio of potassium carbonate to boric acid is 1:0.2. Add absolute ethanol to the ball milling tank for ball milling 5h, dry, pass through a 100-mesh sieve to obtain a mixture, place the mixture in a muffle furnace and calcinate at 800°C for 2h, cool to obtain potassium hexatitanate whiskers, add calcium chloride to deionized water, stir and dissolve to prepare The mass concentration is 5.0% calcium chloride aqueous solution, add potassium hexatitanate whisker and sodium lauryl sulfate to calcium chloride aqueous solution, the mass ratio of potassium hexatitanate whisker and calcium chloride is 1:0.25, The amount of sodium lauryl sulfate added accounts for 0.5% of the mass concentration ...

Embodiment 3

[0046] The preparation method of composite potassium hexatitanate whisker comprises the following steps:

[0047] Mix potassium carbonate, titanium dioxide and boric acid evenly and place them in a ball milling tank. The mass ratio of potassium carbonate to titanium dioxide is 1:4, and the mass ratio of potassium carbonate to boric acid is 1:0.2. Add absolute ethanol to the ball milling tank for ball milling 4h, dry, pass through a 120-mesh sieve to obtain a mixture, put the mixture in a muffle furnace and calcinate at 900°C for 1.5h, cool to obtain potassium hexatitanate whiskers, add calcium chloride to deionized water and stir to dissolve Prepare a calcium chloride aqueous solution with a mass concentration of 5.0%, add potassium hexatitanate whiskers and sodium lauryl sulfate to the calcium chloride aqueous solution, and the mass ratio of potassium hexatitanate whiskers to calcium chloride is 1:0.4 , the addition of sodium lauryl sulfate accounts for 0.5% of the mass conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com