A kind of impact-resistant glass coating and preparation method thereof

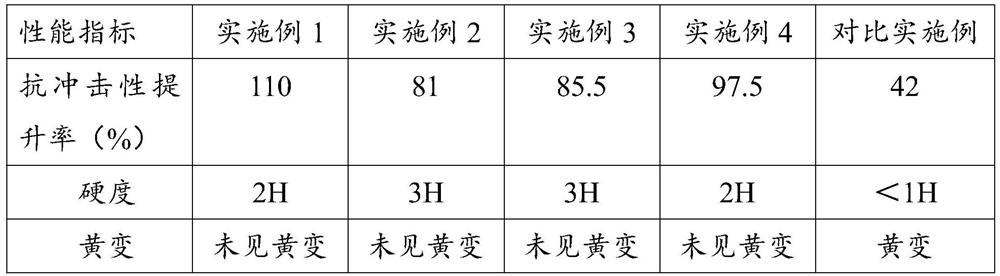

A glass coating and impact-resistant technology, applied in coatings, fire-resistant coatings, etc., can solve the problems of limited impact resistance, soft hardness, and easy yellowing of impact-resistant inks, and achieve improved toughness, elasticity, and strong impact resistance , the effect of improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

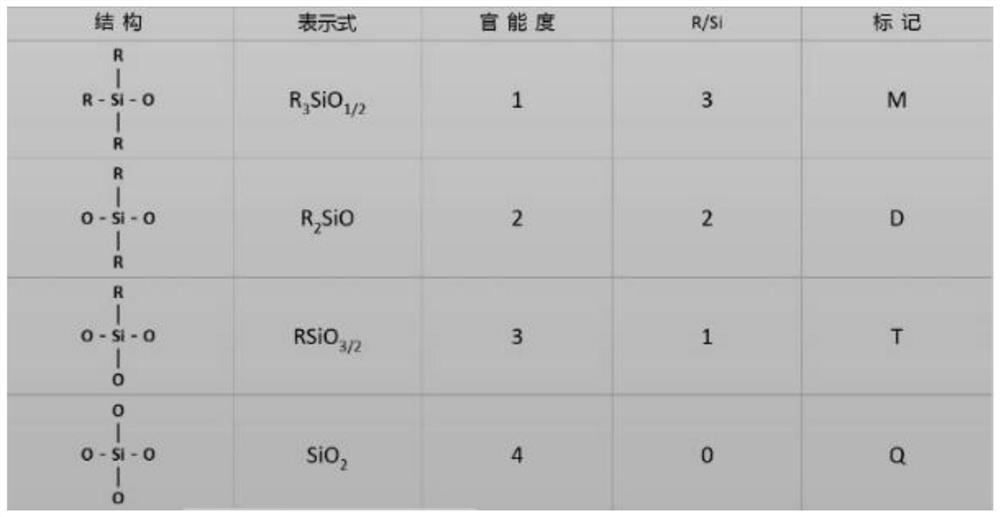

Method used

Image

Examples

Embodiment 1

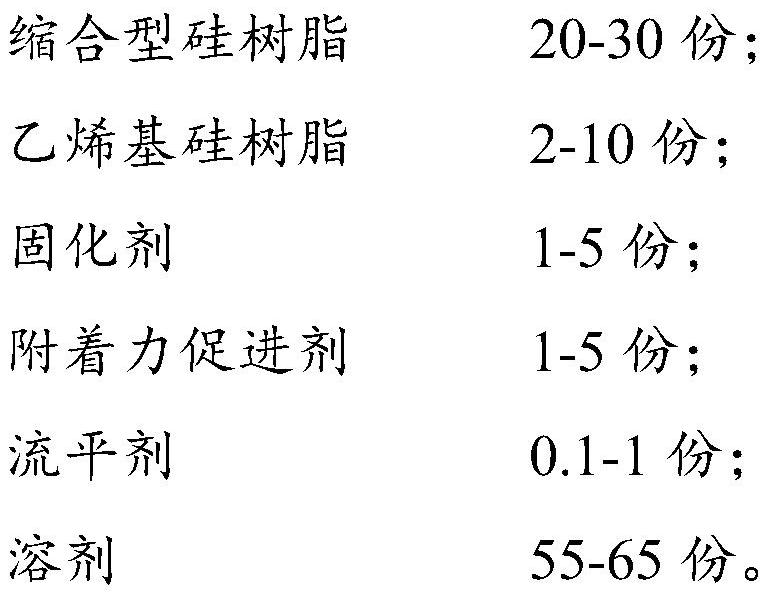

[0027] An impact-resistant glass coating, comprising the following components in parts by weight: 25 parts of T-type-methyl silicone resin, 5 parts of methyl vinyl silicone resin, 1 part of 1-hydroxy-cyclohexyl-phenyl ketone, February: 1 part of dibutyltin silicate, 4 parts of γ-aminopropyltriethoxysilane (KH-550), 0.5 parts of polyether modified silicone and 60 parts of ethyl acetate.

[0028] A preparation method for an impact-resistant glass coating, comprising the following steps:

[0029] S1. Dissolve 25 parts of T-methyl silicone resin in 30 parts of ethyl acetate in parts by weight, and stir magnetically for 1 hour until the T-methyl silicone resin is completely dissolved in ethyl acetate; Add 5 parts of methyl vinyl silicone resin, 4 parts of aminopropyltriethoxysilane (KH-550), 0.5 parts of polyether-modified silicone and another 30 parts of ethyl acetate, and stir magnetically for 2 hours After the stirring is completed, add 1 part of 1-hydroxy-cyclohexyl-phenyl ket...

Embodiment 2

[0033] An impact-resistant glass coating, comprising the following components in parts by weight: 30 parts of T-type-phenyl silicone resin, 2 parts of methylphenyl vinyl silicone resin, 2-hydroxy-2-methyl-1-benzene 0.5 parts of base-1-acetone, 0.5 parts of ethyl orthosilicate, 5 parts of γ-mercaptopropyltrimethoxysilane (KH-590), 1 part of polyester modified silicone and 60 parts of ethyl acetate.

[0034] A preparation method for an impact-resistant glass coating, comprising the following steps:

[0035]S1. Dissolve 30 parts of T-type-phenyl silicone resin in 30 parts of ethyl acetate by weight, and stir magnetically for 1 hour until the T-type-phenyl silicone resin is completely dissolved in ethyl acetate; Add 2 parts of methylphenyl vinyl silicone resin, 5 parts of γ-mercaptopropyl trimethoxysilane (KH-590), 1 part of polyester modified silicone and another 30 parts of ethyl acetate, magnetic Stir for 2 hours; after stirring, add 0.5 part of 2-hydroxy-2-methyl-1-phenyl-1-p...

Embodiment 3

[0039] An impact-resistant glass coating, comprising the following components in parts by weight: 28 parts of T-type-methyl silicone resin, 3 parts of methyl trifluoropropyl vinyl fluorosilicone resin, 1-hydroxy-cyclohexyl-phenyl 1.5 parts of methyl ketone, 1.5 parts of dibutyltin dilaurate, 1 part of γ-mercaptopropyl triethoxysilane (KH-580), 0.1 part of polyether modified silicone and 60 parts of ethyl acetate.

[0040] A preparation method of impact-resistant glass coating, comprising the following steps:

[0041] S1. Dissolve 28 parts of T-type-methyl silicone resin in 30 parts of ethyl acetate by weight, and stir magnetically for 1 hour until the T-type-methyl silicone resin is completely dissolved in ethyl acetate; Add 3 parts of methyl trifluoropropyl vinyl fluorosilicone resin, 1 part of γ-mercaptopropyl triethoxysilane (KH-580), 0.1 part of polyether modified silicone and another 30 parts of acetic acid Ethyl ester, magnetically stirred for 2 hours; after stirring, 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com