Polyethylene composition for hazardous waste storage containers

A technology for storage containers and polyethylene, which is applied in the field of polyethylene compositions for hazardous waste storage containers, and can solve problems such as poor impact resistance, hidden safety hazards for storing nuclear waste, and easy brittleness and rupture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

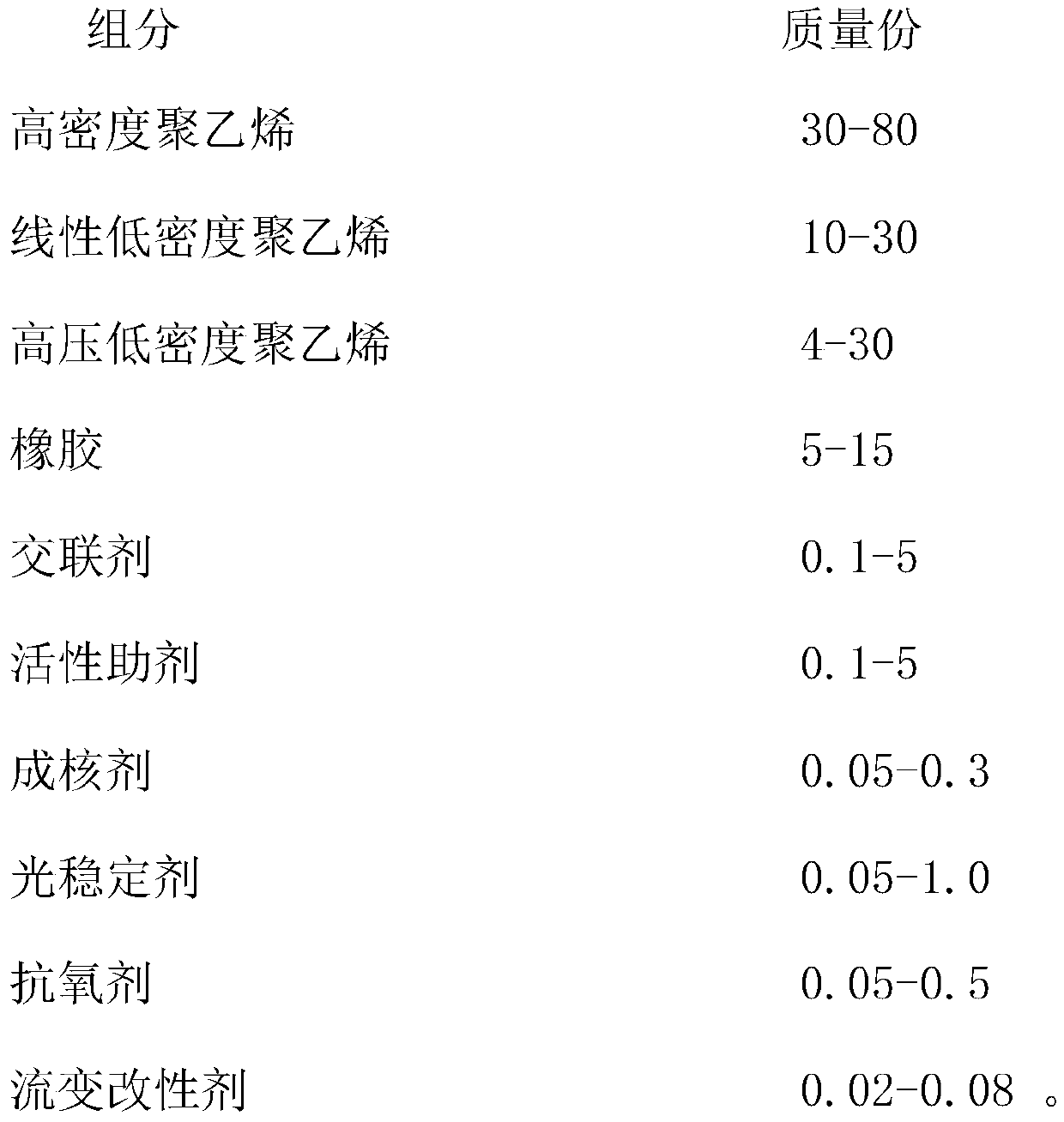

[0027] The polyethylene composition for hazardous waste storage containers includes the following components:

[0028]

[0029]

[0030]Wherein, the density of high-density polyethylene is 0.940g / ml, and the melt flow rate is 5g / 10min; the density of the linear low-density polyethylene is 0.926g / ml, and the melt flow rate is 6g / 10min; the high pressure The density of low-density polyethylene is 0.926 / ml, and the melt flow rate is 20g / 10min.

[0031] The polyethylene composition for hazardous waste storage containers can be prepared by one of the following two preparation methods.

[0032] The first preparation method: first, weigh the components of the above-mentioned parts by mass respectively; secondly, use a mill to grind high-density polyethylene, linear low-density polyethylene, high-pressure low-density polyethylene and silicone rubber into particle sizes 35-100 mesh powder particles, the four kinds of powder particles are uniformly mixed; then, the mixed powder a...

Embodiment 2

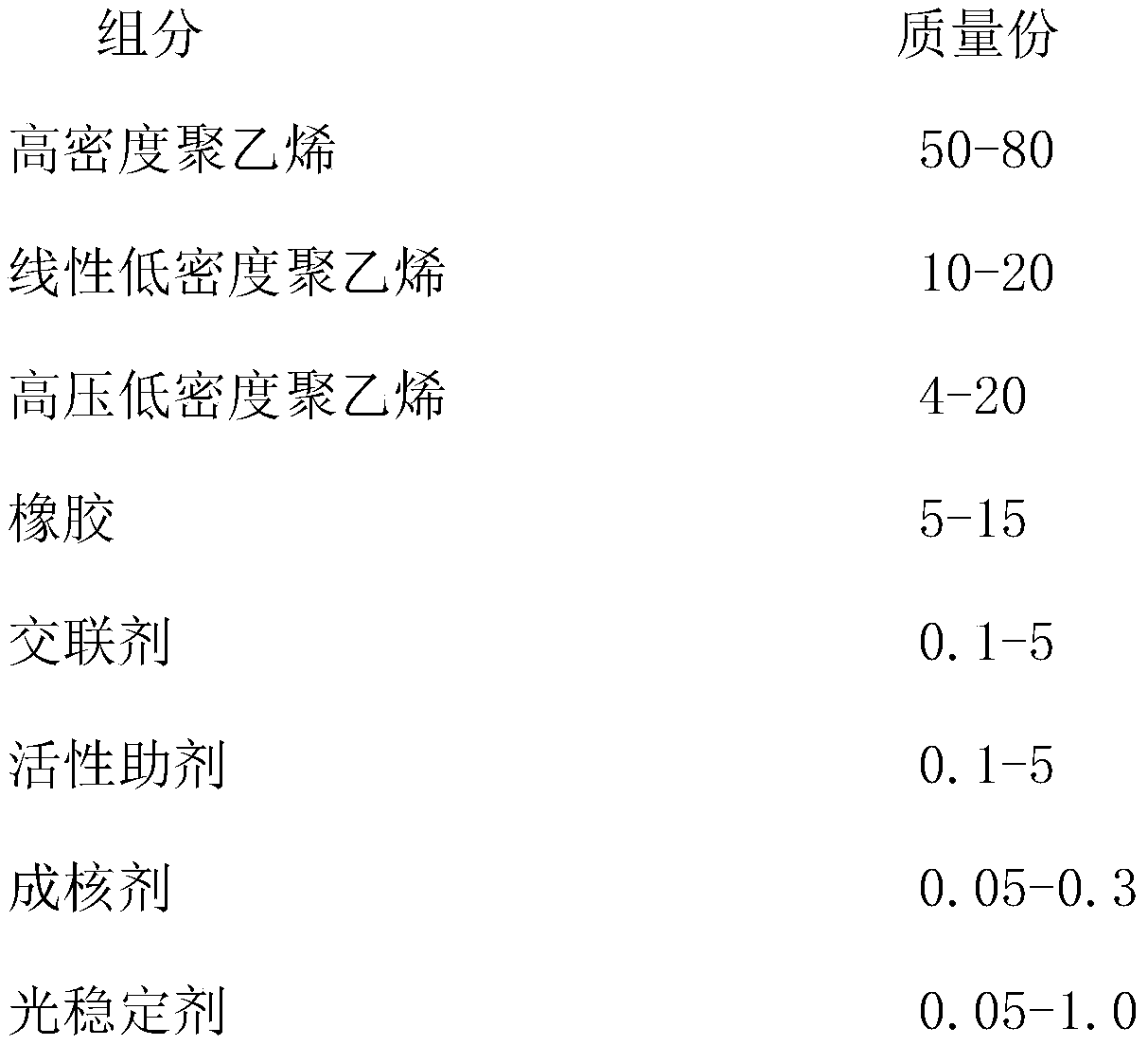

[0035] The polyethylene composition for hazardous waste storage containers includes the following components:

[0036]

[0037]

[0038] Wherein, the density of high-density polyethylene is 0.945g / ml, and the melt flow rate is 7g / 10min; the density of the linear low-density polyethylene is 0.930g / ml, and the melt flow rate is 5g / 10min; the high pressure Low density polyethylene has a density of 0.930 / ml and a melt flow rate of 10g / 10min.

[0039] The preparation method of the polyethylene composition for hazardous waste storage containers is the same as in Example 1.

Embodiment 3

[0041] The polyethylene composition for hazardous waste storage containers includes the following components:

[0042]

[0043]

[0044] Wherein, the density of high-density polyethylene is 0.955g / ml, and the melt flow rate is 12g / 10min; the density of the linear low-density polyethylene is 0.939g / ml, and the melt flow rate is 2.0g / 10min; The density of high-pressure low-density polyethylene is 0.939 / ml, and the melt flow rate is 1.0g / 10min.

[0045] The preparation method of the polyethylene composition for hazardous waste storage containers is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com