Polishing particle and method for manufacturing same, and polishing agent

A manufacturing method and particle technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of increased grinding scratches, inferior sphericity to silicon oxide, defects, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

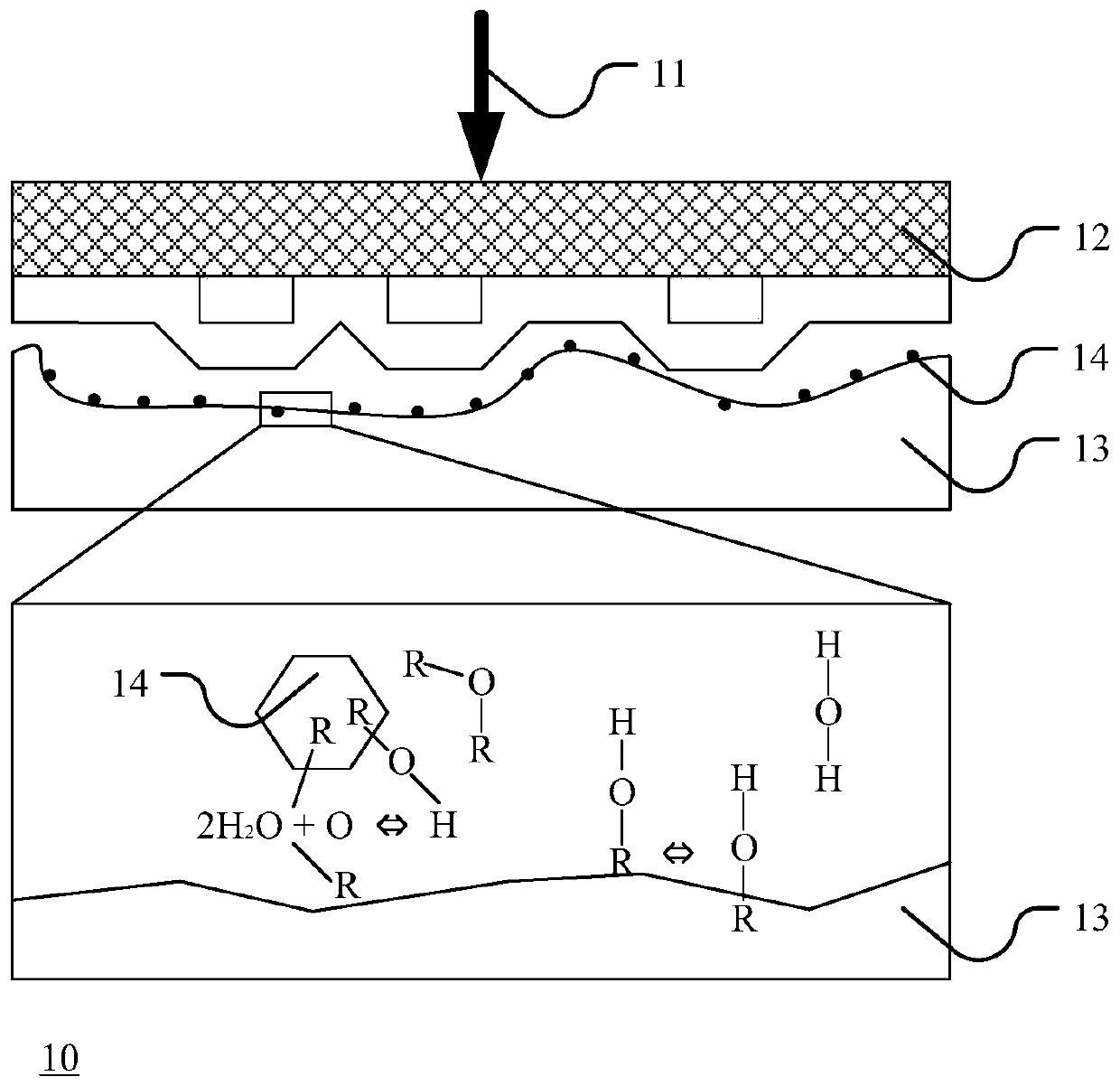

Method used

Image

Examples

Embodiment 2

[0078] In the abrasive particles 300 shown in Embodiment 2, a second core-shell 321 with certain elasticity is added between the core 210 and the first core-shell 322, and the elasticity of the second core-shell 321 is between that of the core 210 and that of the first core-shell. The elasticity of the 322 acts as a transition layer between the core 210 and the first core-shell 322 , which can reduce the probability of damage to the abrasive particles 300 , thereby further reducing scratches on the chip surface.

[0079] exist Figure 8 In the flow chart of the manufacturing method of the abrasive particle in the shown embodiment 2, compared with the embodiment 1, a step of forming the first core-shell is added.

[0080] Step S210: forming core microspheres of abrasive particles.

[0081] Step S220: forming a second core-shell on the surface of the core microsphere.

[0082] In this step, the second core-shell 321 is, for example, a high molecular polymer, which is used to f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com