Preparation method of cellulose polyvinyl alcohol composite film and supercapacitor based on phase inversion

A technology of polyvinyl alcohol and polyvinyl alcohol solution, which is applied in the field of electrochemical materials, can solve the problems of low liquid absorption rate and liquid retention rate, low surface energy, lyophilicity, and poor wettability, and achieve high liquid absorption rate , Good lyophilicity, high liquid retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1) Take an appropriate amount of dry straw, cut it into small pieces of 3 to 4 cm, and then use a universal pulverizer for pulverization (each pulverization takes about 30s), and then screen with a 40-mesh sieve to separate out the cellulose that is required for subsequent experiments. raw material.

[0042] 2) Put the screened powder into a solution with a bath ratio of 50g / L for heating in a water bath, and add an appropriate amount of 40g / L NaOH and 2g / L NaHSO to the solution. 3 , the temperature of the water bath is controlled at 90 degrees Celsius, and the mixture is heated for 4 hours, and during this period, sufficient stirring is performed to facilitate the reaction.

[0043] 3) filter out the solid, add 10g / L sodium chlorite, 5~6ml acetic acid (commercially available concentration 36~38% acetic acid), stir and heat under 70 ℃ of water bath conditions for 4 hours, every 1 hour during the period Add acetic acid once, and add 5-6ml each time. After the water bat...

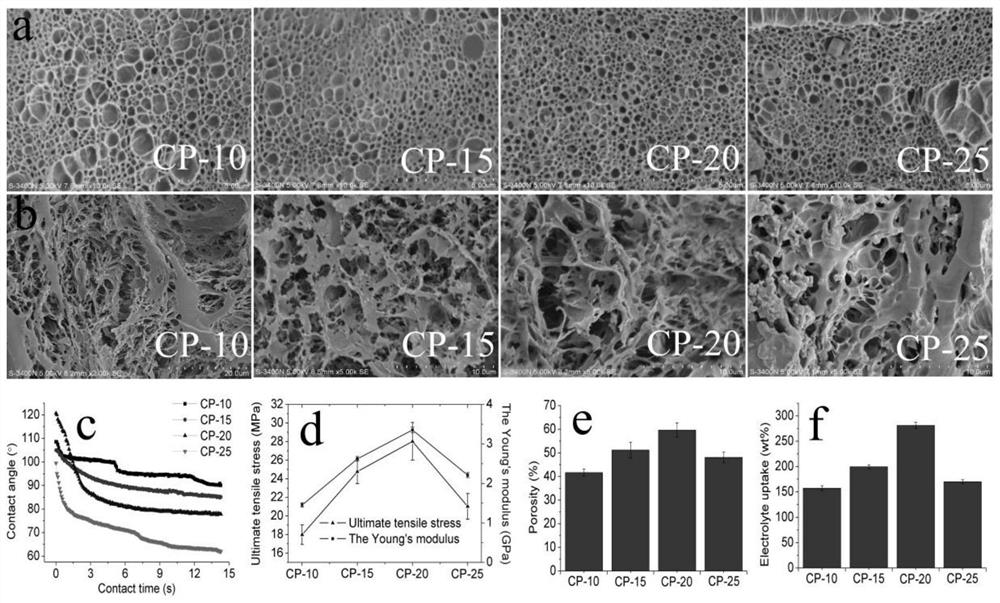

Embodiment 2

[0051] The difference between this example and Example 1 is that the amount of cellulose and polyvinyl alcohol added in step (6) is different (see Table 1 for details), and the prepared composite film is CP-15.

Embodiment 3

[0053] The difference between this example and Example 1 is that the amount of cellulose and polyvinyl alcohol added in step (6) is different (see Table 1 for details), and the prepared composite film is CP-20.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com