Ultra-high molecular weight polyethylene fiber surface continuous ultraviolet grafting treatment system

A polyethylene fiber, ultra-high molecular weight technology, applied in the field of fiber surface treatment, can solve the problems of fiber mechanical properties decline, improper operation, difficult to achieve continuous production, etc., to improve the interface adhesion, mild reaction conditions, and reaction effects excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

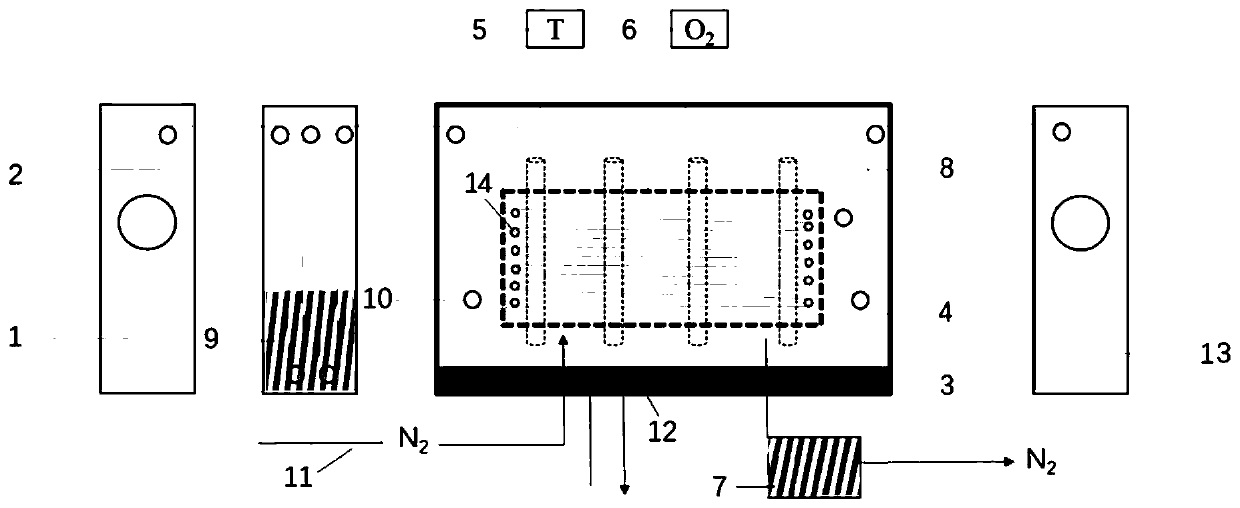

[0030] A continuous ultraviolet grafting treatment system on the surface of ultra-high molecular weight polyethylene fibers, such as figure 1 As shown, including ultraviolet irradiation unit and supporting unit: wherein the ultraviolet irradiation unit is made up of ultraviolet control box 3 and the quartz reactor 4 that is positioned at the ultraviolet control box 3, and quartz reactor 4 has fiber inlet and fiber outlet, and internal setting There are a plurality of quartz rotating shafts 14 for guiding the transmission of the fiber 2, and the ultraviolet lamp 8 for irradiating the quartz reactor 4 and the transmission shaft 10 for guiding the transmission of the fiber 2 are arranged in the ultraviolet control box 3; The solution tank 9 and the fiber rewinding and unwinding mechanism outside the unit, the fiber rewinding and unwinding mechanism is used to drive the fiber through the solution tank 9 and the ultraviolet irradiation unit in sequence.

[0031] In this example, if...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com