Molybdenum-based composite material prepared from microwave sparks as well as method and application thereof

A composite material, molybdenum-based technology, applied in chemical instruments and methods, electrodes, electrolysis process, etc., can solve problems such as rising temperature, achieve the effects of simplifying the preparation process, excellent catalytic activity, and improving the performance of electrocatalytic hydrogen production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

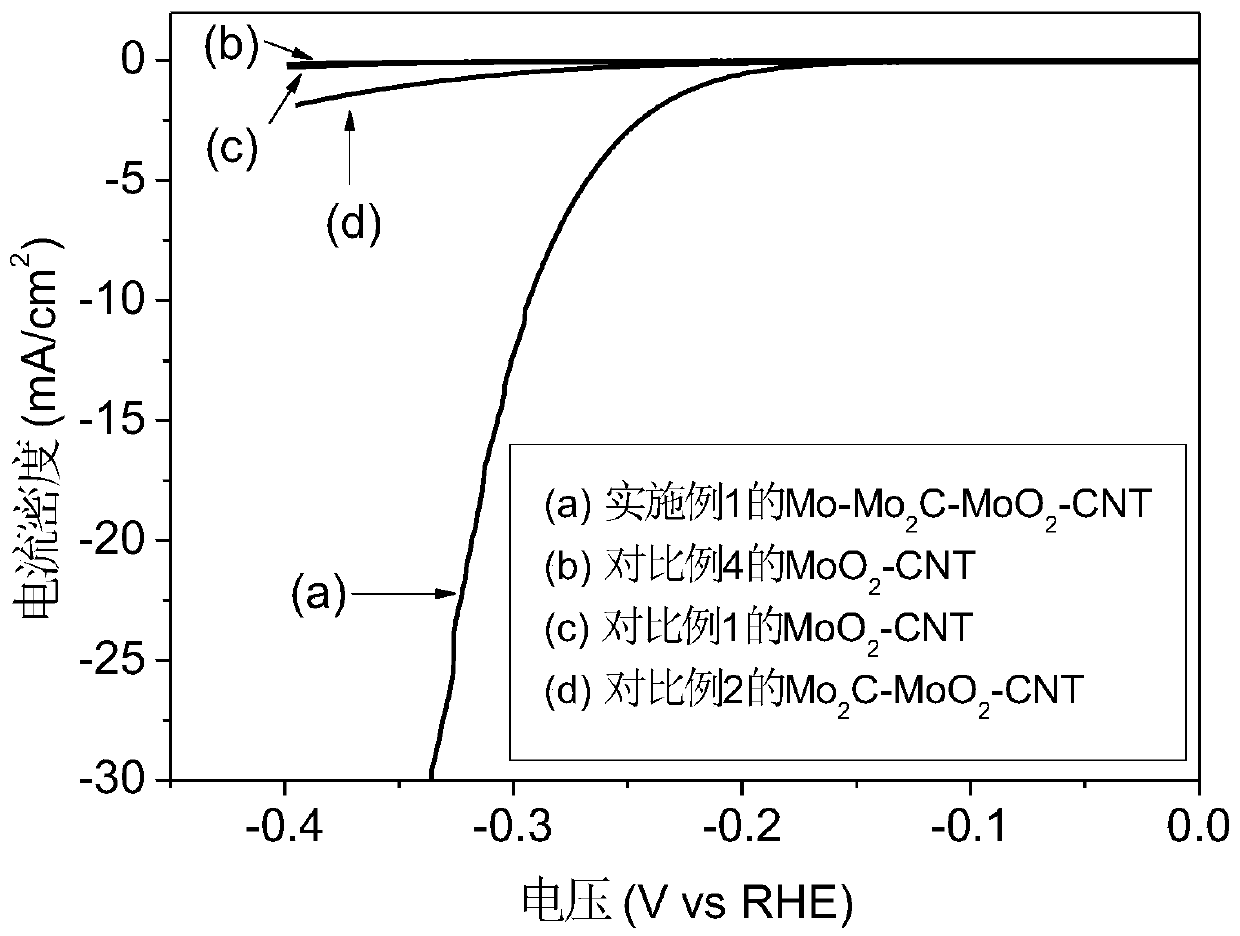

[0046] Embodiment 1 molybdenum-based composite material (being Mo-Mo 2 C-MoO 2 -CNT) preparation

[0047] A method for preparing molybdenum-based composite materials using microwave sparks, the specific preparation process is as follows:

[0048] (1) 0.025g nitrated CNT, 0.036g glucose, 0.6gMoCl 5 Place in a glass vial, drop 50d of cyclohexane, and use ultrasonic to mix evenly; after ultrasonic for 30min, dry in a vacuum oven at 85°C for 11h to obtain a powdery solid, place in a quartz vial, cover with a headspace cap, and pass Argon was used as protective gas.

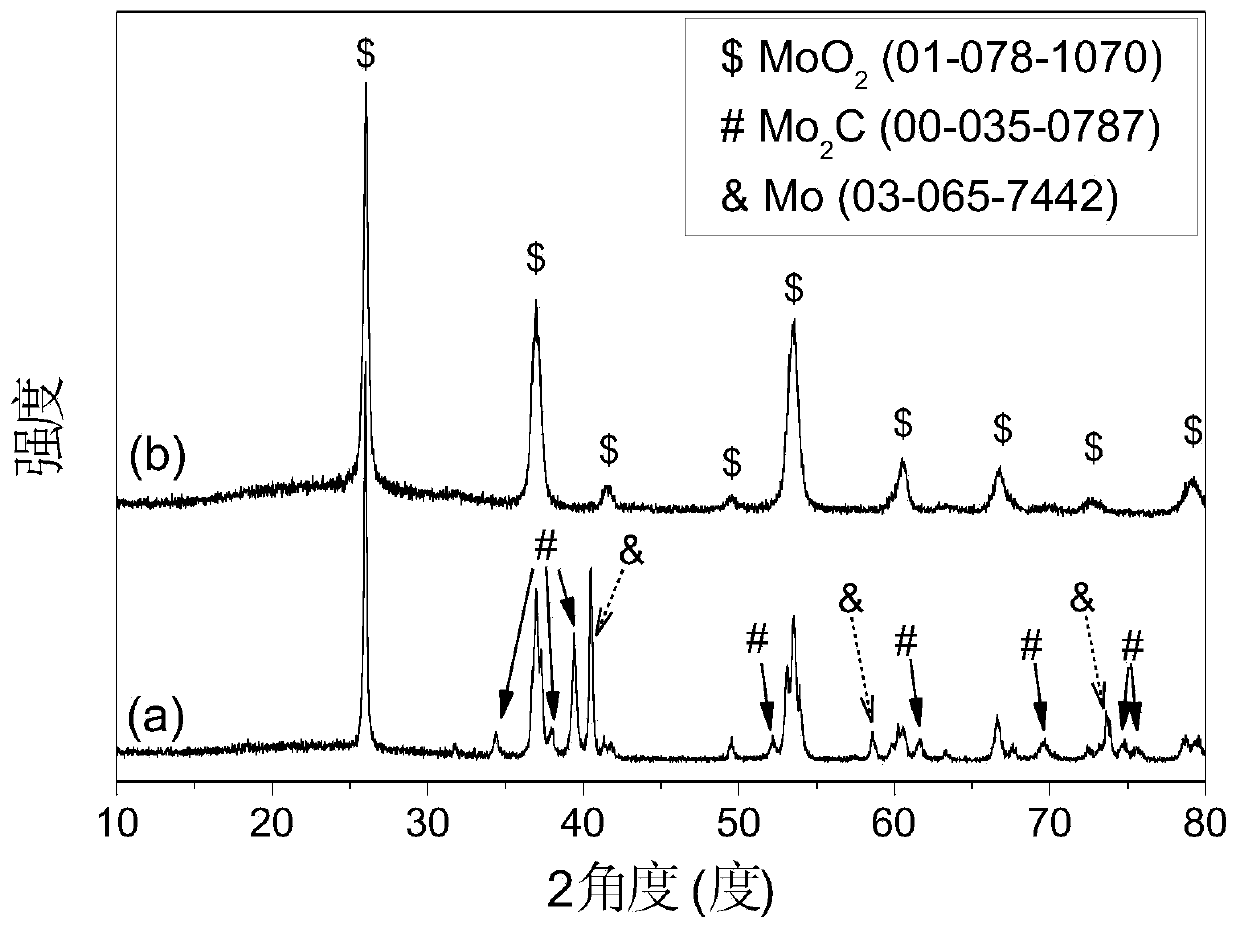

[0049] (2) Then put it into a household microwave oven (frequency is 2.45GHz), microwave at a power of 700W, put it in a ventilated place for one minute in each microwave; Argon exhausts other gases to replace the gas in the bottle, and microwaves for ten minutes to obtain Mo-Mo 2 C-MoO 2 -CNT molybdenum-based composites (such as figure 1 shown in b).

[0050] Wherein, after XRD quantitative analysis, it is fo...

Embodiment 2

[0102] Example 2Mo-Mo 2 C-MoO 2 - Preparation of CNTs

[0103] Concrete preparation process is as follows:

[0104] (1) 0.05g nitrated CNT, 0.036g glucose, 0.6gMoCl 5 Place in a glass vial, drop 50d of n-hexane, and mix evenly with ultrasonic waves; after ultrasonication for 30 min, dry in a vacuum oven at 85°C for 11 h to obtain a powdery solid, place in a quartz vial, cover with a headspace cap, and pass through Argon was used as the shielding gas.

[0105] (2) Remaining steps are the same as in Example 1.

[0106] XRD analysis results show that molybdenum is composed of simple Mo, Mo 2 C. MoO 2 Forms co-exist, get Mo-Mo 2 C-MoO 2 -CNT molybdenum-based composite material.

Embodiment 3

[0107] Example 3Mo-Mo 2 C-MoO 2 - Preparation of GO

[0108] Concrete preparation process is as follows:

[0109] (1) 0.05g nitrated graphene oxide (GO), 0.036g glucose, 0.6gMoCl 5 Place in a glass vial, drop into 50d cyclohexane, and use ultrasonic to mix evenly; ultrasonic for 30min;

[0110] (2) Remaining steps are the same as in Example 1.

[0111] XRD analysis results show that molybdenum is composed of simple Mo, Mo 2 C. MoO 2 Forms co-exist, get Mo-Mo 2 C-MoO 2 -GO molybdenum-based composites.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com