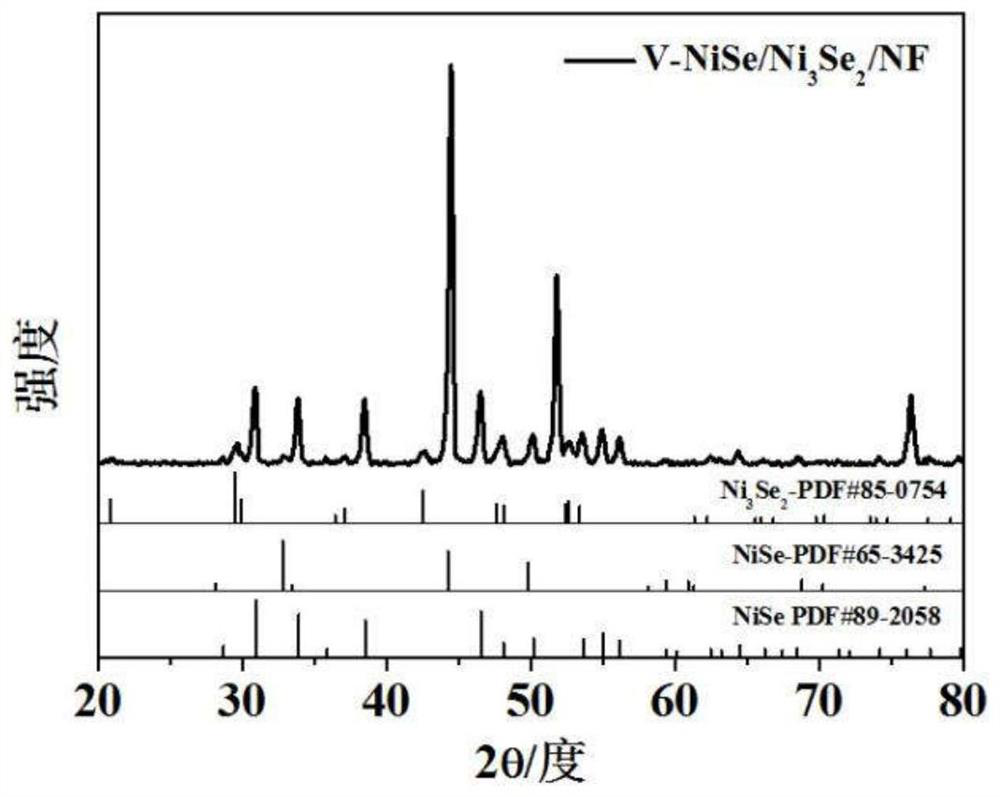

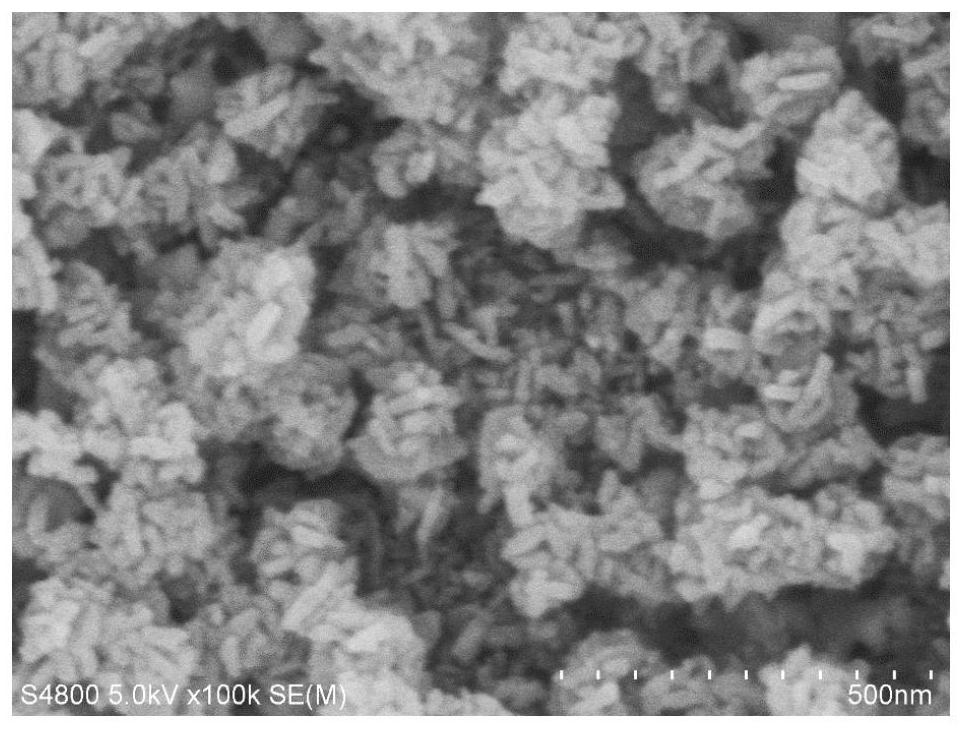

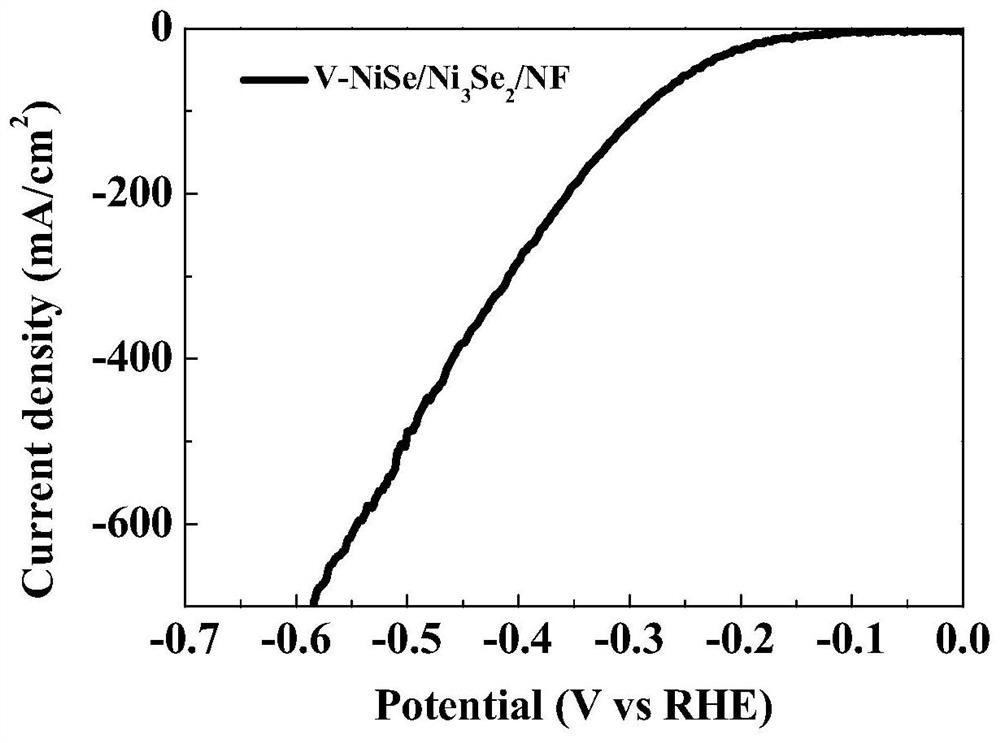

Self-assembled vanadium-modified NiSe/Ni3Se2 self-supporting electrode, synthesis method and application thereof

A technology of self-supporting electrode and synthesis method, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problems of limiting electrocatalyst activity, easy agglomeration, and reducing the exposed area of reaction active sites.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention provides a self-assembled vanadium-modified NiSe / Ni 3 Se 2 The synthesis method of self-supporting electrode comprises the following steps:

[0032] 1) Take the nickel foam and wash and dry it for subsequent use; preferably, the nickel foam is ultrasonically cleaned successively with acetone, hydrochloric acid, deionized water and dehydrated ethanol to remove impurities and oxide layers on the surface of the nickel foam, and wash to neutrality, and wash at normal temperature Drying at low temperature; more preferably, the concentration of hydrochloric acid is 2.8~3.2mol L -1, the ultrasonic treatment time of acetone is 10-15 minutes, and the ultrasonic treatment time of hydrochloric acid, deionized water and absolute ethanol is 5-10 minutes respectively. It should be noted that normal temperature is room temperature, and is defined as 25°C.

[0033] 2) Weigh selenium powder with a mass of 77.96-79.96 mg, add 1.8-2.2 ml of hydrazine hydrate and stir even...

Embodiment 1

[0040] 1) With acetone, the concentration is 3mol L -1 Dilute hydrochloric acid, deionized water and absolute ethanol ultrasonically clean the nickel foam in sequence to remove impurities and oxide layers on the surface, wash until neutral, and dry at room temperature to obtain the desired nickel foam;

[0041] 2) Weigh 78.90 mg of selenium powder and pour it into a beaker, add 2 ml of hydrazine hydrate and stir magnetically at 45° C. for 1.2 h to obtain solution A;

[0042] 3) Weighing 34.825 mg of sodium metavanadate as a morphology regulator of vanadium source and 28 mg of polyallylamine hydrochloride;

[0043] 4) Add the mixed solution A in step 2)) and the vanadium source and shape regulator weighed in step 3) into a high-temperature and high-pressure reactor with 20mL of pure water and a parapolystyrene liner. Stir to obtain solution B;

[0044] 5) Put 220-225 mg of nickel foam treated in step 1) into a high-temperature and high-pressure reaction kettle with a p-polyst...

Embodiment 2

[0047] 1) With acetone, the concentration is 3mol L -1 Dilute hydrochloric acid, deionized water and absolute ethanol ultrasonically clean the nickel foam in sequence to remove impurities and oxide layers on the surface, wash until neutral, and dry at room temperature to obtain the desired nickel foam;

[0048] 2) Weigh 78.58mg of selenium powder and pour it into a beaker, add 2ml of hydrazine hydrate and stir magnetically at 47°C for 1.2h to obtain solution A;

[0049] 3) Weighing 34.829mg of sodium metavanadate as a vanadium source and 25mg of polyallylamine hydrochloride as a morphology regulator;

[0050] 4) Add the vanadium source and the morphology regulator of mixed solution A in step 2) and step 3) to a high-temperature and high-pressure reactor with 19 mL of pure water and a parapolyphenyl liner, and stir magnetically at room temperature to obtain Solution B;

[0051] 5) Put 220-225 mg of nickel foam treated in step 1) into a high-temperature and high-pressure react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com