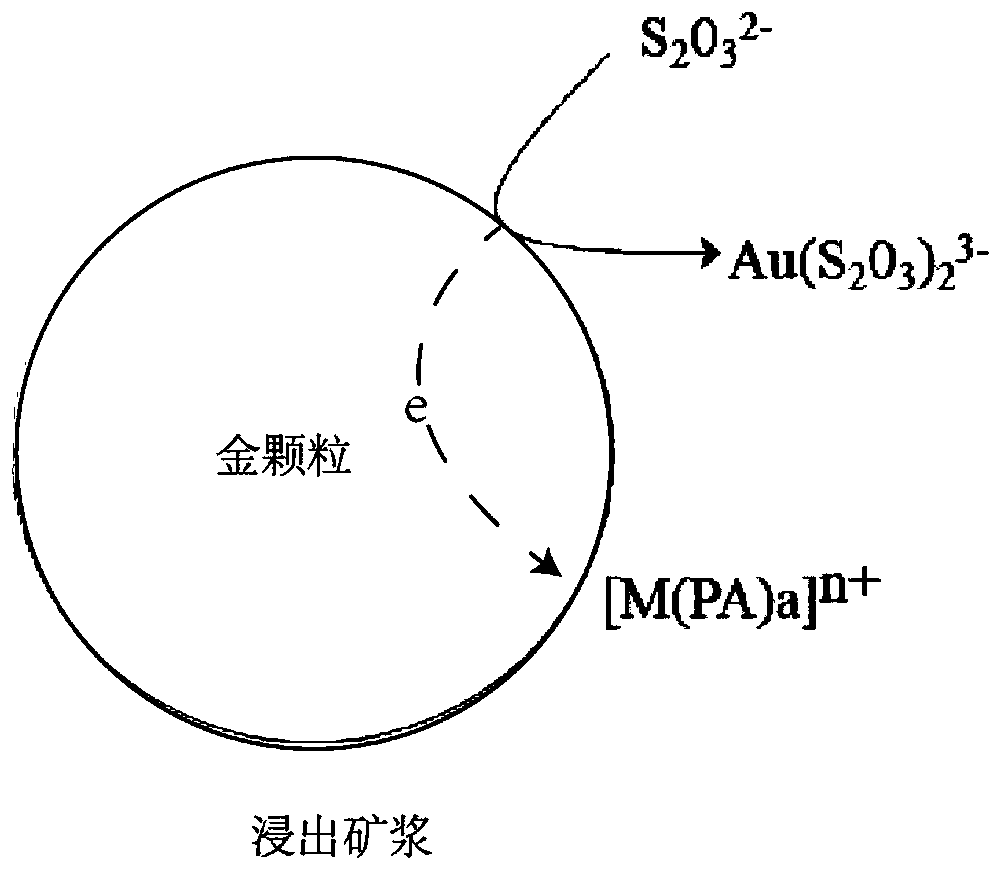

Thiosulfate gold leaching method and application

A thiosulfate and leaching technology, applied in the field of hydrometallurgy, can solve the problems of gold extraction process interference, hindering gold leaching, consumption of thiosulfate leaching agent, etc., so as to avoid safety and environmental impact problems and reduce harmful ions Concentration, improve the effect of excessive consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

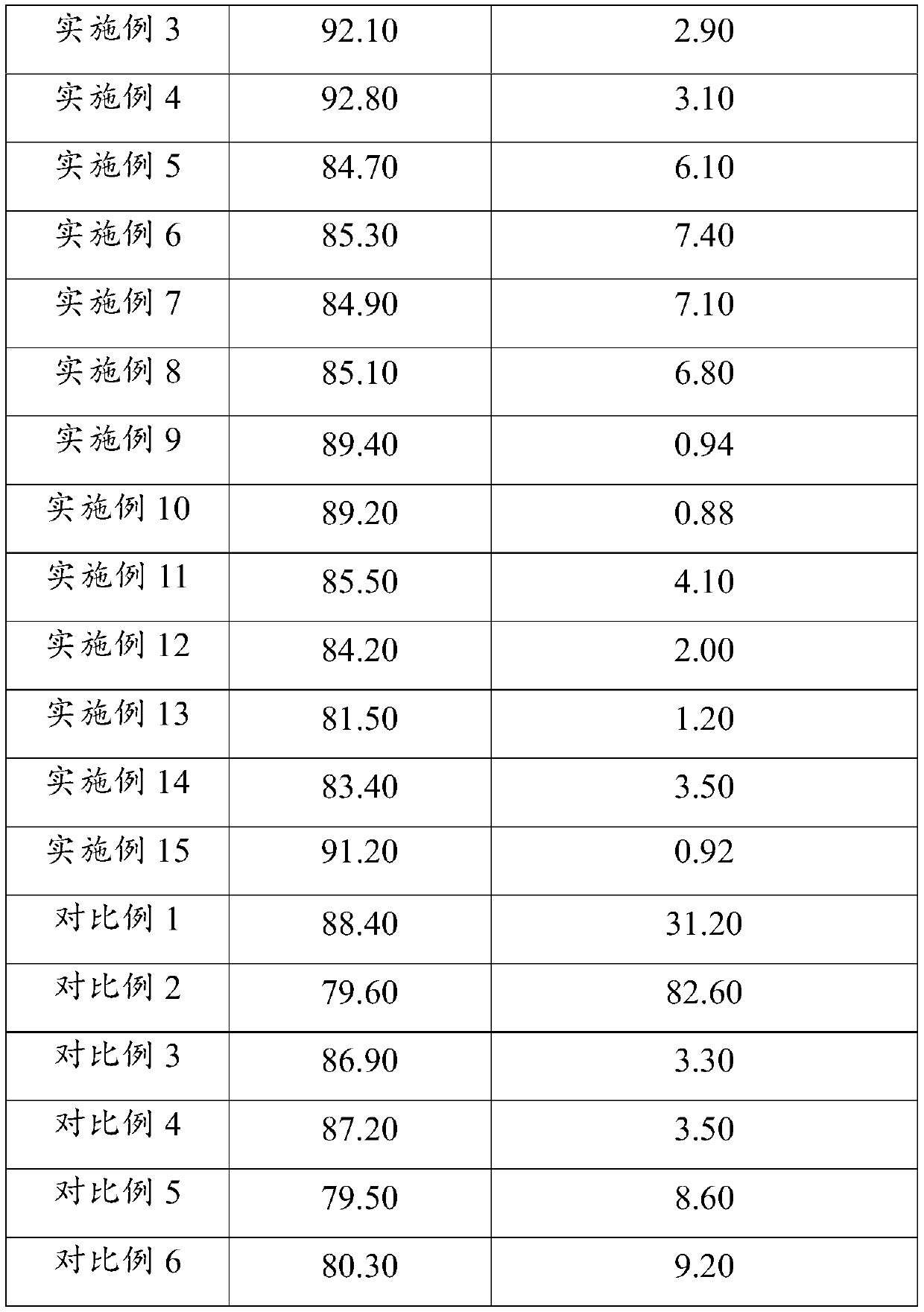

[0053] As an optional embodiment of the present invention, the metal salts include copper sulfate, manganese sulfate, iron sulfate, zinc sulfate, copper chloride, manganese chloride, ferric chloride, zinc chloride, copper nitrate, manganese nitrate, iron nitrate Or any one or a combination of at least two of zinc nitrates.

[0054] As an optional embodiment of the present invention, the initial concentration of the metal salt in the solvent is 0.0008-0.20 mol / dm 3 . A typical but non-limiting initial concentration of the metal salt in the solvent is 0.0008 mol / dm 3 , 0.001mol / dm 3 , 0.002mol / dm 3 , 0.005mol / dm 3 , 0.008mol / dm 3 , 0.01mol / dm 3 , 0.02mol / dm 3 , 0.10mol / dm 3 , 0.12mol / dm 3 , 0.14mol / dm 3 , 0.15mol / dm 3 , 0.16mol / dm 3 , 0.18mol / dm 3 or 0.20mol / dm 3 .

[0055] If the initial concentration of metal salt in the solvent is too low or too high, the leaching rate of gold and the consumption of thiosulfate will be adversely affected, so the initial concent...

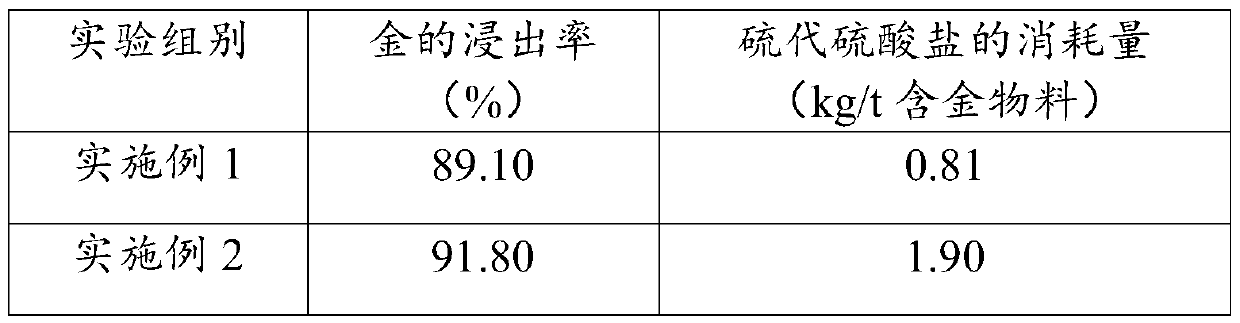

Embodiment 1

[0080] The present embodiment provides a kind of thiosulfate gold leaching method, comprises the following steps:

[0081] (a) Provide gold-bearing slurry formed by gold-bearing materials and solvents:

[0082] Crushing and wet-grinding the gold-containing material to -0.074mm accounts for 90%, adjusting the mass fraction of the gold-containing material in the gold-containing slurry to 45%, and obtaining the gold-containing slurry;

[0083] Among them, the gold-bearing material is oxidized ore of a gold mine, the gold content is 3.58g / t, the main gangue mineral is quartz; the solvent is water;

[0084] (b) adding metal salt, polycarboxylate additives and thiosulfate to the above-mentioned gold-containing pulp for leaching to obtain the leached pulp, adjusting the pH value of the leached pulp to 7.0, mechanical stirring and leaching, the stirring speed is 100r / min, The leaching temperature is 20°C, and the leaching time is 8.0h;

[0085] Wherein, the metal salt is a mixture o...

Embodiment 2

[0087] The present embodiment provides a kind of thiosulfate gold leaching method, comprises the following steps:

[0088] (a) gold-containing ore pulp is identical with the gold-containing ore pulp of step (a) in embodiment 1;

[0089] (b) adding metal salt, polycarboxylate additives and thiosulfate to the above-mentioned gold-containing pulp for leaching to obtain the leached pulp, adjusting the pH value of the leached pulp to 9.0, mechanical stirring and leaching, the stirring speed is 200r / min, The leaching temperature is 90°C, and the leaching time is 4.0h;

[0090] Among them, the metal salt is a mixture of copper chloride, manganese sulfate and zinc chloride (the ratio of the amount of the three substances is 2:1:1), and the initial concentration of the metal salt in the solvent is 0.006mol / dm 3 The polycarboxylate additive is a mixture of sodium polyacrylate, potassium polyacrylate and ammonium polyacrylate (the ratio of the amount of the three substances is 1:1:1), a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com