Gold concentrate oxidizing slag gold leaching process

A gold concentrate and oxidation slag technology, applied in the direction of improving process efficiency, etc., to achieve high gold leaching rate, low cost, and simple treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

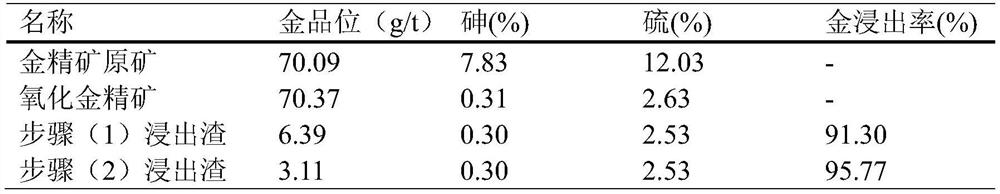

Embodiment 1

[0027] This embodiment provides a process for leaching gold from oxidized slag of gold concentrate. After oxidation of high-sulfur arsenic gold concentrate in a certain area of Jiangxi, this process is used for non-cyanide gold leaching. The specific steps are as follows:

[0028] (1) Take 100g of gold concentrate oxidation slag, add leaching solution 280ml and activated carbon, add water 20ml, use sodium hydroxide to adjust the pH value to 10, add an appropriate amount of ammonium thiocyanate solid, control the mass fraction of ammonium thiocyanate to 15% of the leaching solution , stirring and leaching at normal temperature and pressure for 7 hours, after the leaching is completed, take out the gold-loaded carbon, test its gold content, weigh the weight of the leaching residue, and calculate the leaching rate.

[0029] (2) Add 10ml of water to the leached pulp obtained in step (1), add an appropriate amount of ammonium thiocyanate solid, control the mass fraction of ammoniu...

Embodiment 2

[0036] This embodiment provides a process for leaching gold from oxidized slag of gold concentrate. After oxidation of high-sulfur arsenic gold concentrate in a certain area of Jiangxi, this process is used for non-cyanide gold leaching. The specific steps are as follows:

[0037] (1) Get 100g of gold concentrate oxidation slag, add leaching solution 280ml and activated carbon, add water 20ml, use calcium oxide to adjust the pH value to 12, add an appropriate amount of ammonium thiocyanate solid, control the ammonium thiocyanate mass fraction to be 10% of the leaching solution, Stir and leaching at normal temperature and pressure for 4 hours, take out the gold-loaded carbon after the leaching is completed, test its gold content, weigh the weight of the leaching residue, and calculate the leaching rate.

[0038] (2) Add 10ml of water to the leach pulp obtained in step (1), add an appropriate amount of ammonium thiocyanate solid, control the mass fraction of ammonium thiocyanat...

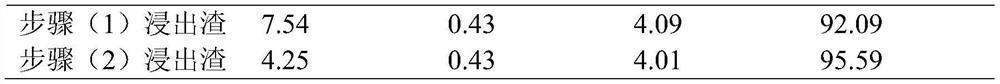

Embodiment 3

[0044] This embodiment provides a process for leaching gold from oxidation slag of gold concentrate. After oxidation of high-sulfur arsenic gold concentrate in a certain area in Hunan, this process is used for non-cyanide gold leaching. The specific steps are as follows:

[0045] (1) Get 100g of gold concentrate oxidation slag, add leaching solution 280ml and activated carbon, add water 20ml, use calcium oxide to adjust the pH value to 11, add an appropriate amount of ammonium thiocyanate solid, control the ammonium thiocyanate mass fraction to be 5% of the leaching solution, Stir and leaching at normal temperature and pressure for 5 hours. After the leaching is completed, take out the gold-loaded carbon, test its gold content, weigh the weight of the leaching residue, and calculate the leaching rate.

[0046] (2) Add 10ml of water to the leach pulp obtained in step (1), add an appropriate amount of ammonium thiocyanate solid, control the mass fraction of ammonium thiocyanate t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com