A kind of environment-friendly gold leaching agent and preparation method thereof

A gold leaching agent and environmental protection technology, which is applied in the field of environmental protection gold leaching agent and its preparation, can solve the problems of environmental pollution and high toxicity, and achieve the effects of simple production process, increased gold leaching rate, and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

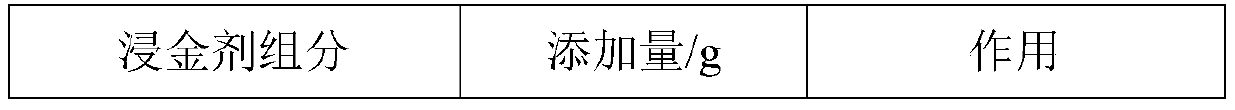

Image

Examples

Embodiment 1

[0023] Gold leaching agent components Amount added / g effect sodium ethylate 20 strong base sodium hydroxide 15 strong base Sodium fluorosilicate 11 anticoagulant silica 6 anticoagulant Sodium Polydisilicate 12 Soaking aid 4A zeolite 8 Soaking aid Melamine ammonium cyanurate 10 synergist Antimony trioxide 5 synergist potassium pyrophosphate 5 Chelating agent sodium oxalate 2 Chelating agent

[0024] The preparation method is as follows:

[0025] S1, take strong alkali, anticoagulant, leaching aid, chelating agent by weight, after mixing evenly, fully grind, pass through 100 mesh sieve, set aside;

[0026] S2. Put the material obtained in step S1 into a crucible, pass through a muffle furnace, and bake at 700° C. for 2.5 hours, take it out, let it stand, and cool to room temperature;

[0027] S3, crushing the cooled material in step S2 to 100 mesh;

[0028] S4. Mix the pulverized ma...

Embodiment 2

[0033] Gold leaching agent components Amount added / g effect sodium ethylate 20 strong base sodium hydroxide 15 strong base Sodium fluorosilicate 11 anticoagulant silica 6 anticoagulant Sodium Polydisilicate 12 Soaking aid 4A zeolite 8 Soaking aid Melamine ammonium cyanurate 5 synergist Antimony trioxide 1 synergist potassium pyrophosphate 3.5 Chelating agent sodium oxalate 1 Chelating agent

[0034] The preparation method is as follows:

[0035] S1, take strong alkali, anticoagulant, leaching aid, chelating agent by weight, after mixing evenly, fully grind, pass through 100 mesh sieve, set aside;

[0036] S2. Put the material obtained in step S1 into a crucible, pass through a muffle furnace, and bake at 750° C. for 2.5 hours, take it out, let it stand, and cool it to room temperature;

[0037] S3, crushing the cooled material in step S2 to 100 mesh;

[0038] S4. Mix the pulverize...

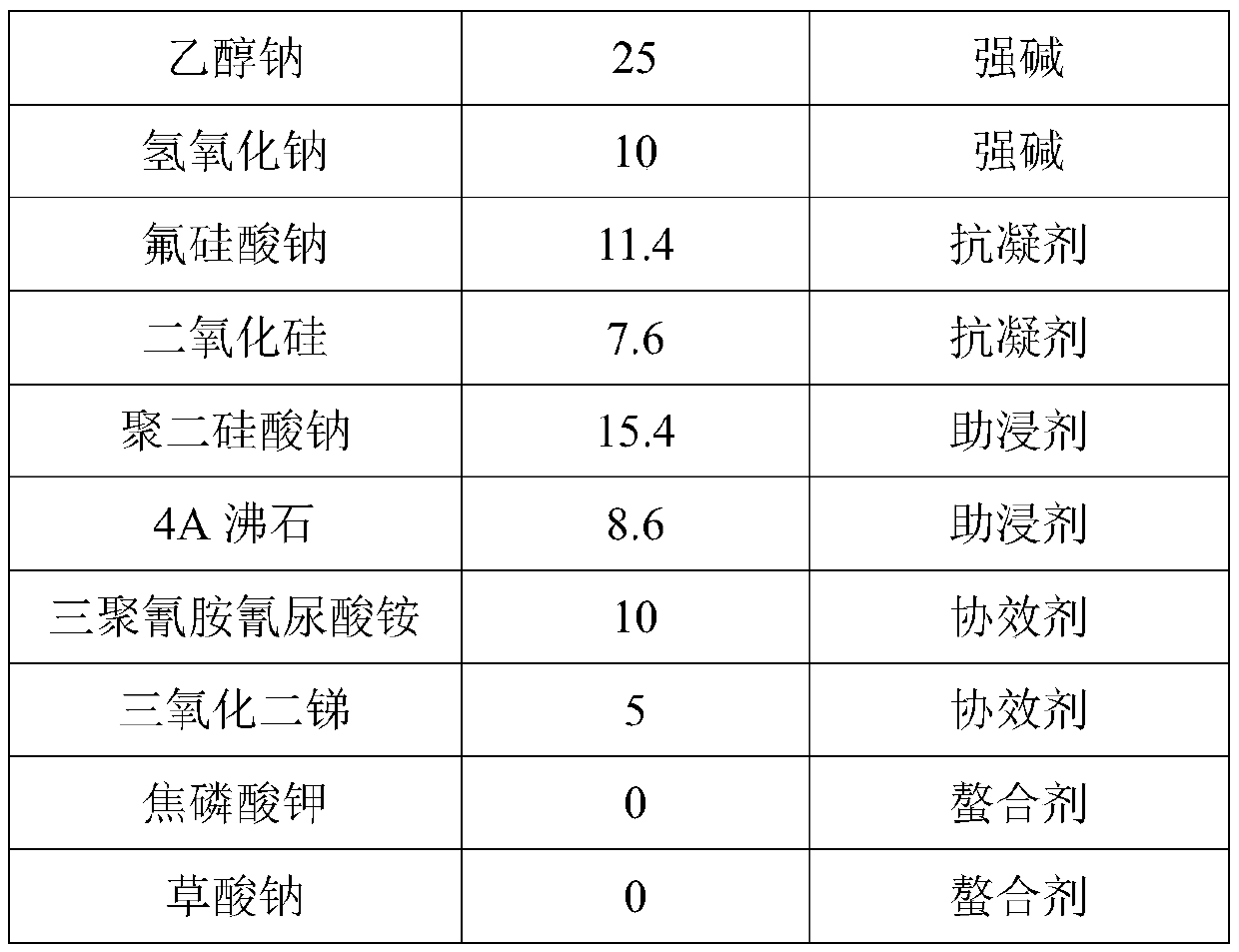

Embodiment 3

[0042] Gold leaching agent components Amount added / g effect sodium ethylate 25 strong base sodium hydroxide 10 strong base Sodium fluorosilicate 11.4 anticoagulant silica 7.6 anticoagulant Sodium Polydisilicate 15.4 Soaking aid 4A zeolite 8.6 Soaking aid Melamine ammonium cyanurate 10 synergist Antimony trioxide 5 synergist potassium pyrophosphate 5 Chelating agent sodium oxalate 2 Chelating agent

[0043] The preparation method is as follows:

[0044] S1, take strong alkali, anticoagulant, leaching aid, chelating agent by weight, after mixing evenly, fully grind, pass through 100 mesh sieve, set aside;

[0045] S2. Put the material obtained in step S1 into a crucible, pass through a muffle furnace, and bake at 700° C. for 2.5 hours, take it out, let it stand, and cool to room temperature;

[0046] S3, crushing the cooled material in step S2 to 100 mesh;

[0047] S4. Mix the pulve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com