Water-absorbing profile adjusting sleeve pipe and adjusting method for water injection well

A water absorption profile and adjustment method technology, which is applied to chemical instruments and methods, earthwork drilling and production, wellbore/well components, etc., can solve the problems of short effective period of measures, low efficiency of measures, and lack of pertinence, so as to reduce the pipe string Corrosion, the effect of solving uneven water flooding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

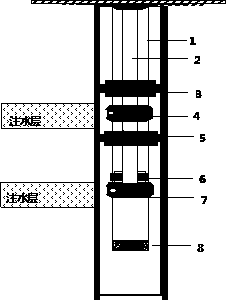

[0023] like figure 1 As shown, a casing for adjusting the water absorption profile of a water injection well includes a first oil pipe 1, a plug 8 is connected to the lower end of the first oil pipe 1, and casing packers 3, The first water distributor 4, the interlayer packer 5, the intubation seal 6 and the second water distributor 7, the first oil pipe 1 is connected with the first water distributor 4, the first oil pipe 1 is also provided with the second oil pipe 2, the second The second oil pipe 2 is connected to the second water distributor 7 .

[0024] The first tubing 1 is connected to the wellhead, the end of the first tubing 1 is connected with a plug, and the casing packer 3, the first water distributor 4, and the interlayer packer are sequentially sleeved outside the first tubing 1 from top to bottom 5. The intubation seal 6 and the second water distributor 7. The second oil pipe 2 is also connected to the wellhead and placed in the first oil pipe 1. The first oil ...

Embodiment 2

[0030] A method for adjusting the water absorption profile of a water injection well,

[0031] In the first step, the casing is run in, and the casing for adjusting the water absorption profile of the water injection well is run into the water injection well;

[0032] The second step is to adjust the water absorption profile. For the two water injection layers, one layer has weak water absorption due to formation blockage, and the other layer has strong water absorption. Through one of the water distributors, the strong water absorption layer is treated with diversion acidification technology. Plugging, through another water distributor to acidify and increase the injection of the weak water absorption layer, the acid liquid system in the split acidification technology adopts chelating acid, polyhydric acid or authigenic acid liquid system, and passes through the strong water absorption layer and the weak water absorption layer Separated by multiple packers;

[0033] Adjust t...

Embodiment 3

[0041] When using the split acidification technology to block the strong water-absorbing layer, if the oil well corresponding to the water injection well in the strong water-absorbing layer has high water content and the oil well is flooded quickly, the diversion agent in the split-flow acidizing technology uses an oil-soluble plugging agent to seal the strong water-absorbing layer. Permanent plugging prevents water from entering the strong water-absorbing layer; the oil-soluble blocking agent is insoluble in acid and insoluble in water.

[0042] If the water injection well in the strong water-absorbing layer corresponds to low water content in the oil well, and the oil-water well has good connectivity, the water-soluble plugging agent used in the diversion agent in the diversion acidification technology can temporarily block the strong water-absorbing layer. After the construction is completed and the water is injected again, the plugging agent It will automatically dissolve i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com