Bismuth sulfide mineral inhibiting agent and application thereof

A technology of inhibitors and minerals, applied in solid separation, flotation, etc., to achieve the effects of reducing mineral processing costs, stable processes, and safe operating environments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

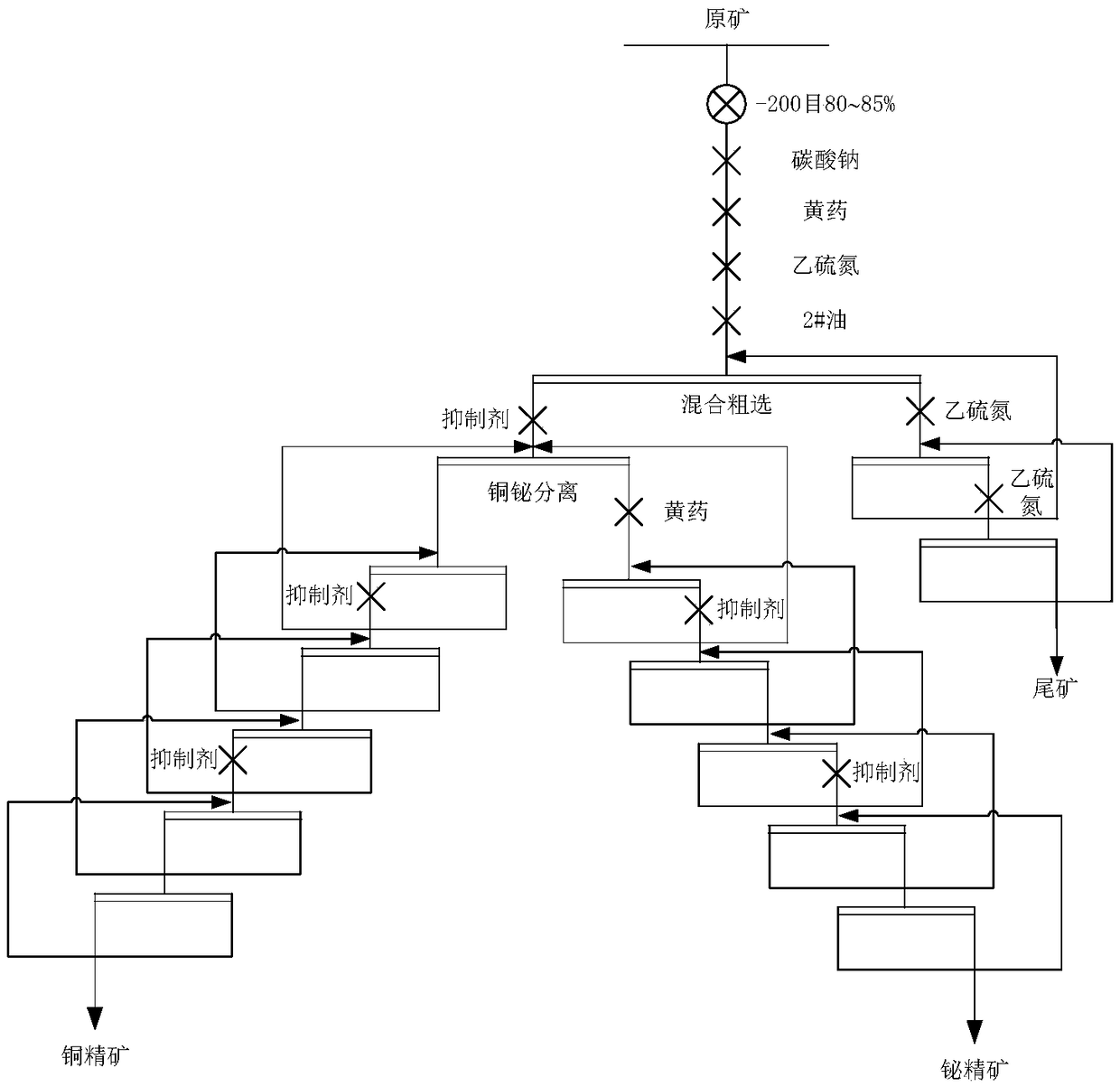

Method used

Image

Examples

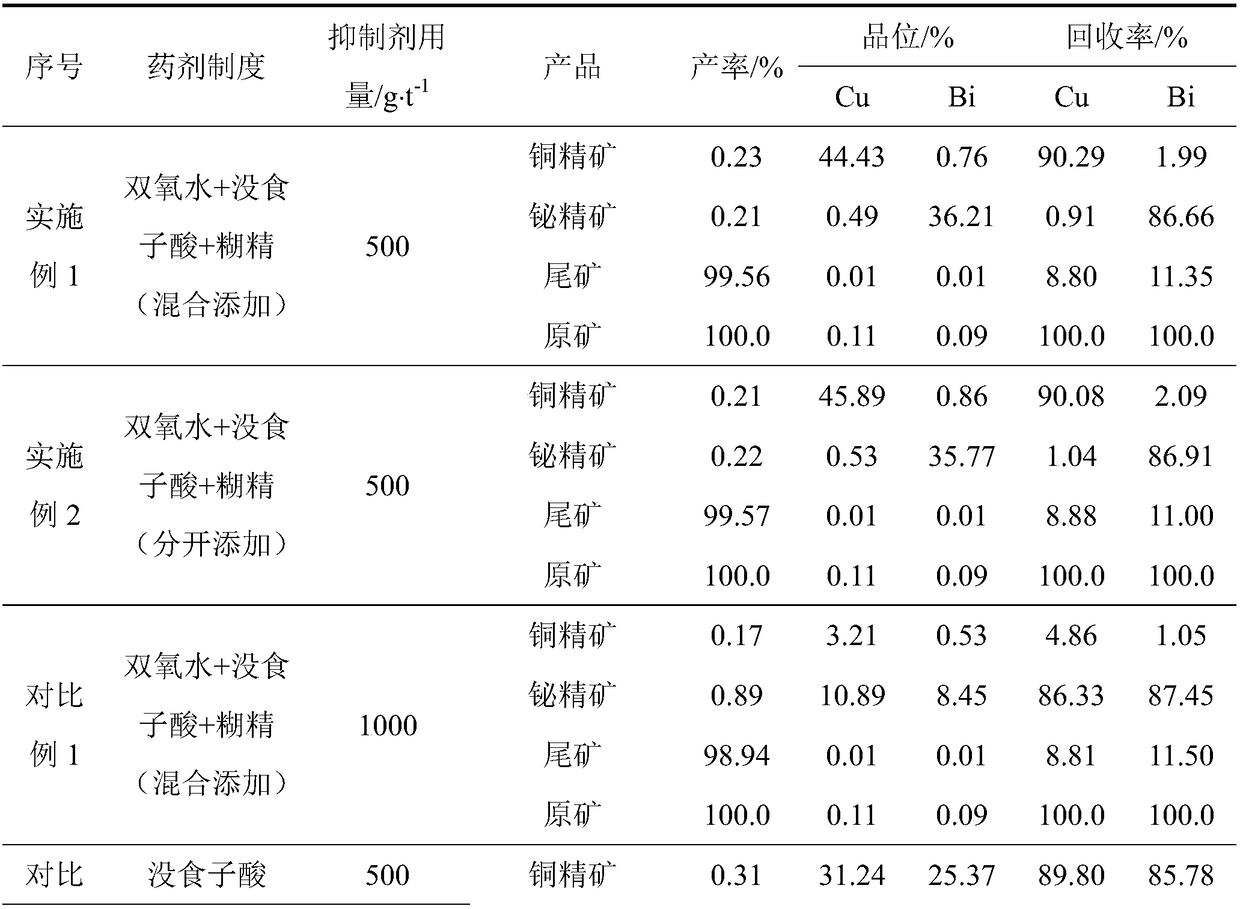

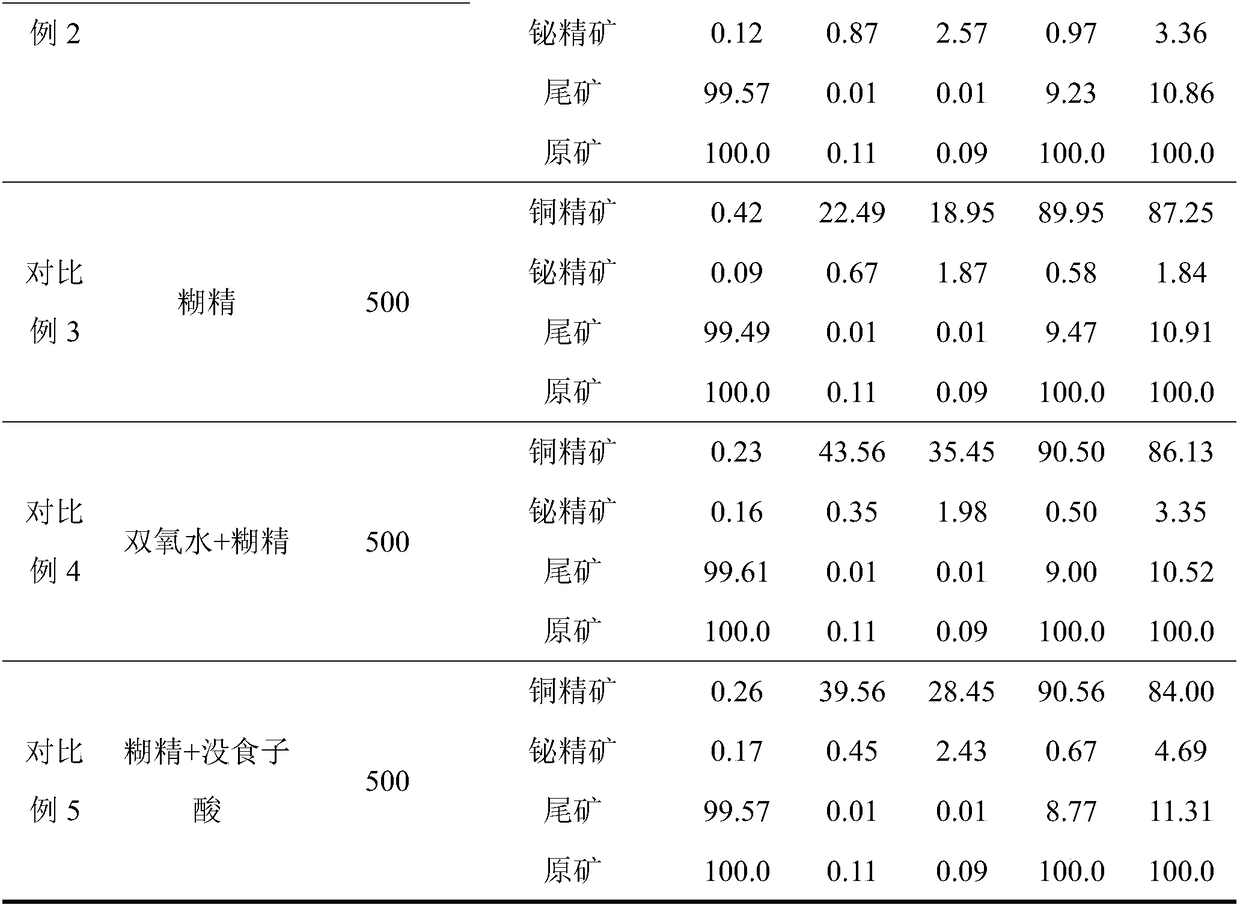

Embodiment 1

[0052] 1. Mineral raw materials

[0053] A copper-bismuth sulfide ore in a place in Jiangxi Province was taken, with a copper grade of 0.11% and a bismuth grade of 0.09%. Among them, the copper-bearing minerals are mainly chalcopyrite, and the bismuth-bearing minerals are mainly bismuthite.

[0054] 2. The operation steps and technical conditions are as follows:

[0055] ① Grind the raw copper-bismuth sulfide ore to -200 mesh, accounting for 80-85%, and add sodium carbonate to adjust the pH of the slurry to 8-9;

[0056] ②Add 300g / t xanthate, stir for 3 minutes, add 80g / t ethyl disulfide, stir for 3 minutes, add 25g / t 2# oil, stir for 3 minutes, then carry out mixed roughing operation to obtain mixed roughing concentrate and mixed roughing tailings;

[0057]③ Weigh 3 parts of hydrogen peroxide, 3 parts of gallic acid and 1 part of dextrin according to parts by mass. After mixing, add 500g / t to the roughing concentrate. After stirring for 3 minutes, separate copper and bismu...

Embodiment 2

[0061] 1. Mineral raw materials

[0062] A copper-bismuth sulfide ore in a place in Jiangxi Province was taken, with a copper grade of 0.11% and a bismuth grade of 0.09%. Among them, the copper-bearing minerals are mainly chalcopyrite, and the bismuth-bearing minerals are mainly bismuthite.

[0063] 2. The operation steps and technical conditions are as follows:

[0064] ① Grind the raw copper-bismuth sulfide ore to -200 mesh, accounting for 80-85%, and add sodium carbonate to adjust the pH of the slurry to 8-9;

[0065] ②Add 300g / t xanthate, stir for 3 minutes, add 80g / t ethyl disulfide, stir for 3 minutes, add 25g / t 2# oil, stir for 3 minutes, then carry out mixed roughing operation to obtain mixed roughing concentrate and mixed roughing tailings;

[0066] ③ Weigh 3 parts of hydrogen peroxide, 3 parts of gallic acid and 1 part of dextrin in parts by mass, add them separately to the mixed roughing concentrate at an amount of 500g / t, stir for 3 minutes and carry out the sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com