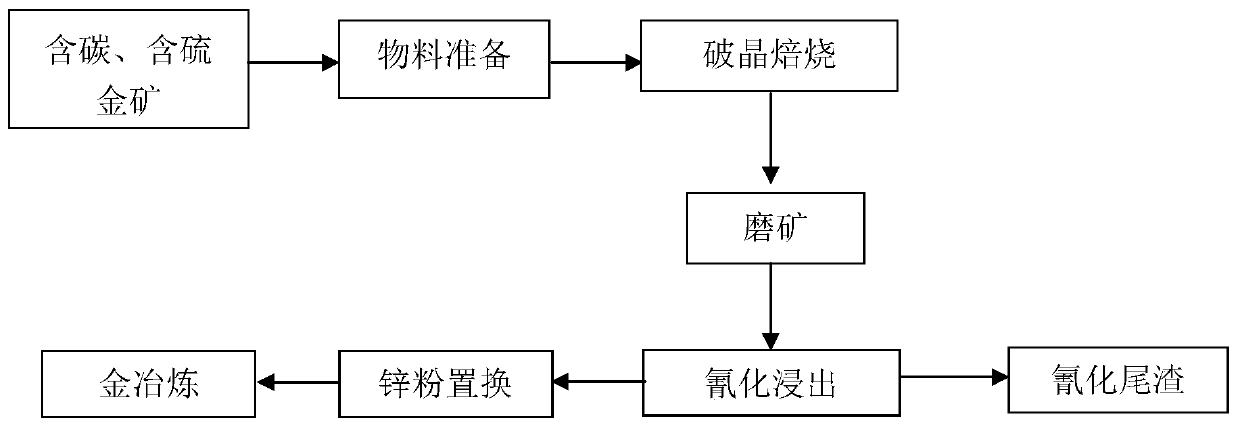

Mineral-separation gold extraction method adopting suspension roasting treatment of sulfur-containing and carbon-containing gold ore

A technology for suspension roasting and gold ore is applied in the field of mineral processing, which can solve the problem of low gold recovery rate, and achieve the effects of high heat utilization rate, saving dosage and reducing Fe ion content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A carbon-bearing gold rough concentrate in Sichuan, with a gold grade of 30g / t and a carbon content of 7.34%.

[0027] A method for beneficiating and extracting gold by suspending and roasting sulfur-containing and carbon-containing gold ores, the specific operation steps are as follows:

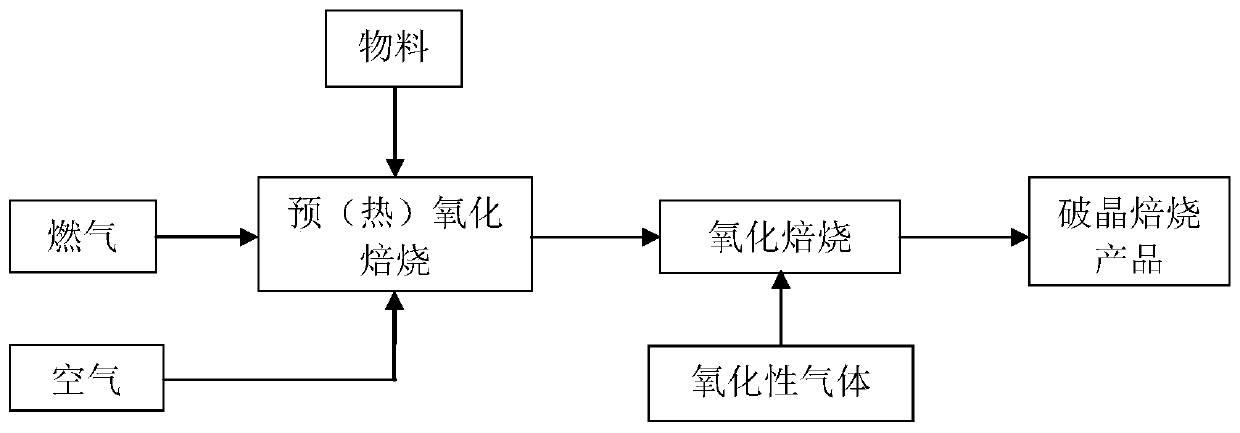

[0028] 1) Feed carbon-containing gold ore with an ore particle size below 0.074mm into the reaction chamber of the suspension roasting system for crystal breaking roasting, wherein the roasting temperature is 400°C, the roasting time is 10 minutes, and sufficient air is introduced during roasting;

[0029] 2) Add the crystal-broken roasted product obtained in the previous step into a stirring tank for slurry mixing, and then perform grinding with a ceramic medium stirring mill, the grinding concentration is 50%, and the grinding fineness-0.045mm particle size content is 90%;

[0030] 3) For the product after grinding, sodium cyanide is used for cyanidation leaching, the amount of sodi...

Embodiment 2

[0034] A sulfur-bearing gold tailing in Jiangxi, with a gold grade of 3.89g / t and a sulfur content of 6.14%.

[0035] A method for beneficiating and extracting gold by suspending and roasting sulfur-containing and carbon-containing gold ores, the specific operation steps are as follows:

[0036] 1) Feed the sulfur-containing gold tailings into the reaction chamber of the suspension roasting system for crystal breaking roasting, wherein the roasting temperature is 500°C, the roasting time is 10 hours, and sufficient air is introduced during roasting;

[0037] 2) Add the crystal-broken roasted product obtained in the previous step into a stirring tank for slurry mixing, and then perform grinding with a ceramic medium stirring mill, the grinding concentration is 50%, and the grinding fineness-0.038mm particle size content is 98%;

[0038] 3) For the product after grinding, use sodium cyanide for cyanidation leaching, the amount of sodium cyanide is 10kg / t, the leaching concentrat...

Embodiment 3

[0042] A carbon-bearing gold mine in Shaanxi, with a gold grade of 4.5g / t and a carbon content of 6.5%.

[0043] A method for beneficiating and extracting gold by suspending and roasting sulfur-containing and carbon-containing gold ores, the specific operation steps are as follows:

[0044] 1) Feed the carbon-containing gold ore whose ore particle size is crushed to below 1 mm into the reaction chamber of the suspension roasting system, and carry out crystal breaking roasting, wherein the roasting temperature is 900 ° C, the roasting time is 20 minutes, and sufficient air is introduced during roasting;

[0045] 2) Add the crystal-broken roasted product obtained in the previous step into a stirring tank for slurry mixing, and then perform grinding with a ceramic medium stirring mill, the grinding concentration is 50%, and the grinding fineness-0.045mm particle size content is 93%;

[0046] 3) For the product after grinding, sodium cyanide is used for cyanidation leaching, the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com