Preparation method of food packaging film based on bacterial nanocellulose

A technology of nanocellulose and packaging film, which is applied in the field of food packaging film, can solve the problems of large application area of food packaging, insufficient biological activity function, poor biodegradability, etc., and achieve high cost performance, good commercial application prospects, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

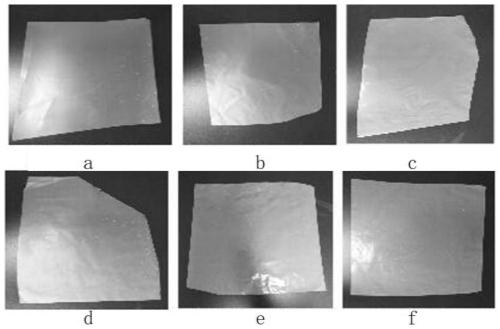

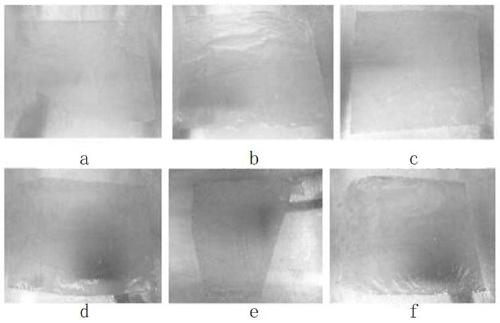

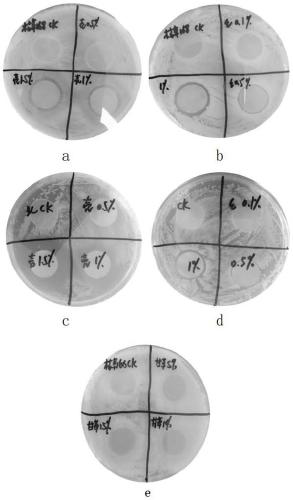

Image

Examples

Embodiment 1

[0034] The present embodiment relates to the preparation method of BC antibacterial composite film, specifically comprises:

[0035] ①Preparation of film-forming solution: Weigh 10% of starch, 1% of bacterial nanocellulose, 1% of sorbitol, and 2% of glycerin in turn, and mix and prepare film-forming solution. Cellulose, specifically Gluconacetobacter xylinus TDS-114, was preserved in the China General Microorganism Collection Center (CGMCC) on March 30, 2020, with the preservation number CGMCC No.19536. The Gluconacetobacter xylinus High-yielding strains from a mutagenesis screen isolated from grapevines and mutagenized with 1-methyl-3-nitro-1-nitrosoguanidine (NTG).

[0036] ②Film-forming liquid treatment: The obtained film-forming liquid was stirred and gelatinized at 90°C for 30 minutes on a constant temperature magnetic stirrer (85-2, Shanghai Chijiu);

[0037] ③Addition of antibacterial agent: Add different antibacterial agents to the film-forming solution after gelatini...

Embodiment 2

[0044] This embodiment relates to the preparation method of the BC composite film containing Chinese herbal medicine components, specifically including:

[0045] Step 1) preparation of Chinese herbal medicine extract, specifically comprising:

[0046] ①Put 200g of licorice and cinnamon purchased from the market (purchased from Taobao) in an oven at 60°C and dry to constant weight;

[0047] ②Crush and grind the dried licorice and cinnamon with constant weight, and weigh 50-150g of the powder;

[0048] ③Add 500mL of 95% ethanol according to the ratio of solid to liquid 1:10, soak and ultrasonically (SK300B, Shanghai Kedao Ultrasonic Instrument Co., Ltd.) for 2-4h;

[0049] ④ Filter with a 200-mesh sieve and collect the filtrate and filter residue respectively, and store the filtrate for future use;

[0050] ⑤ Add 200-500mL of 95% ethanol to the collected filter residue, soak and sonicate for 2-4h;

[0051] ⑥ filter and collect the filtrate;

[0052] ⑦ Combine the filtrates c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com